Electric earthing switch arrangement for gas insulated substation

A gas-insulated, earthing switch technology, applied in earthing switches, electrical switches, switchgear and other directions, can solve problems such as expensive and expensive switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

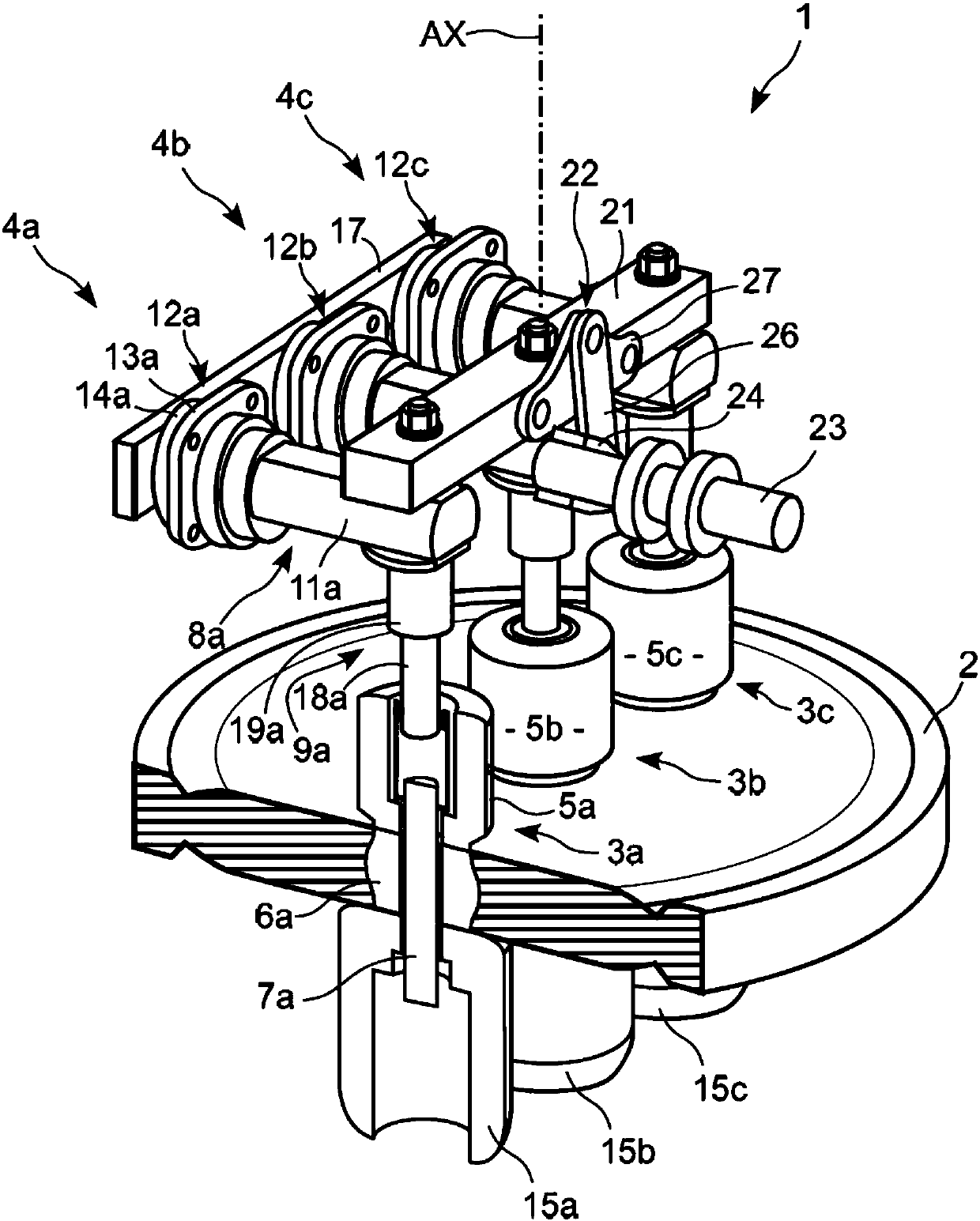

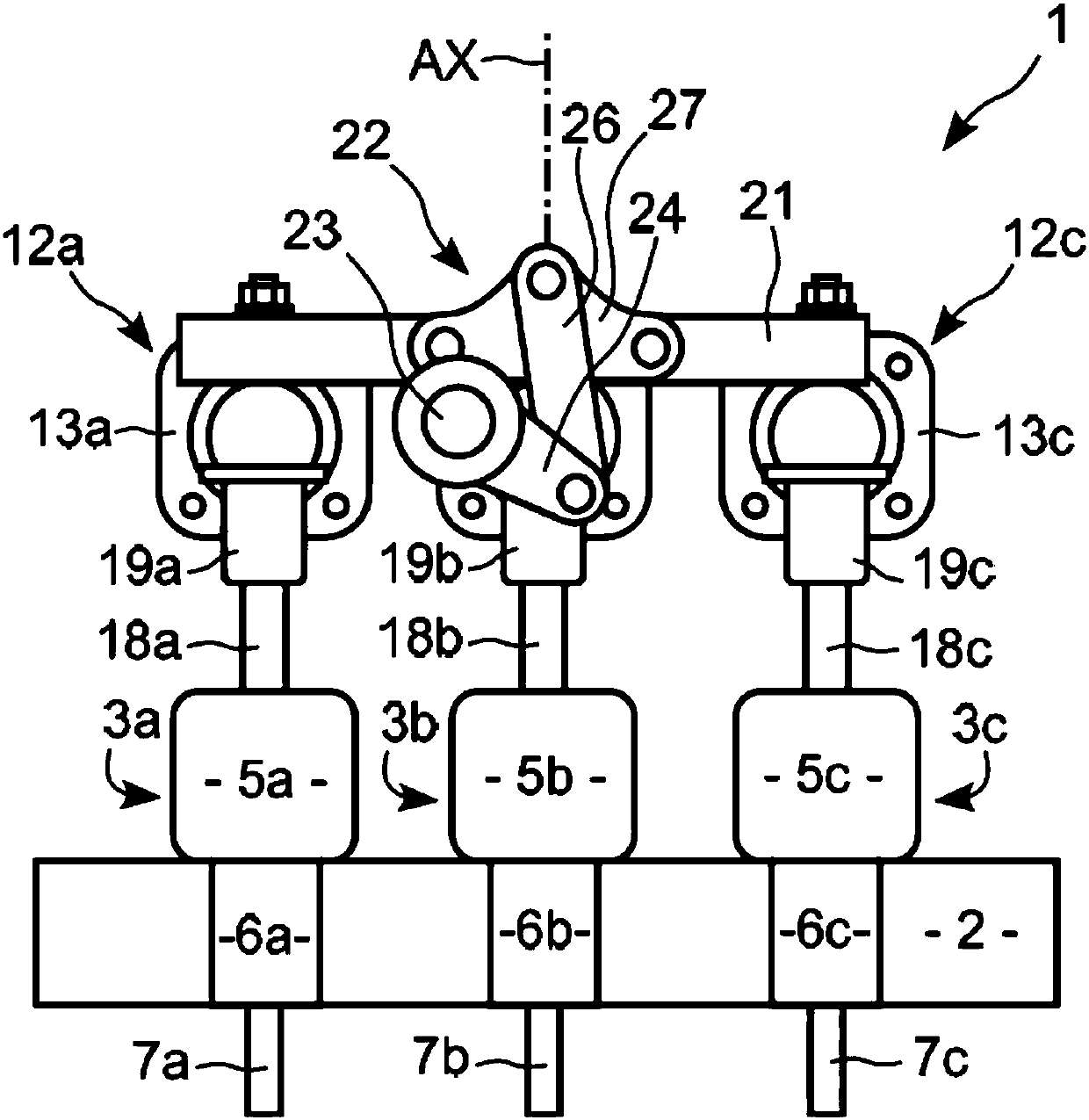

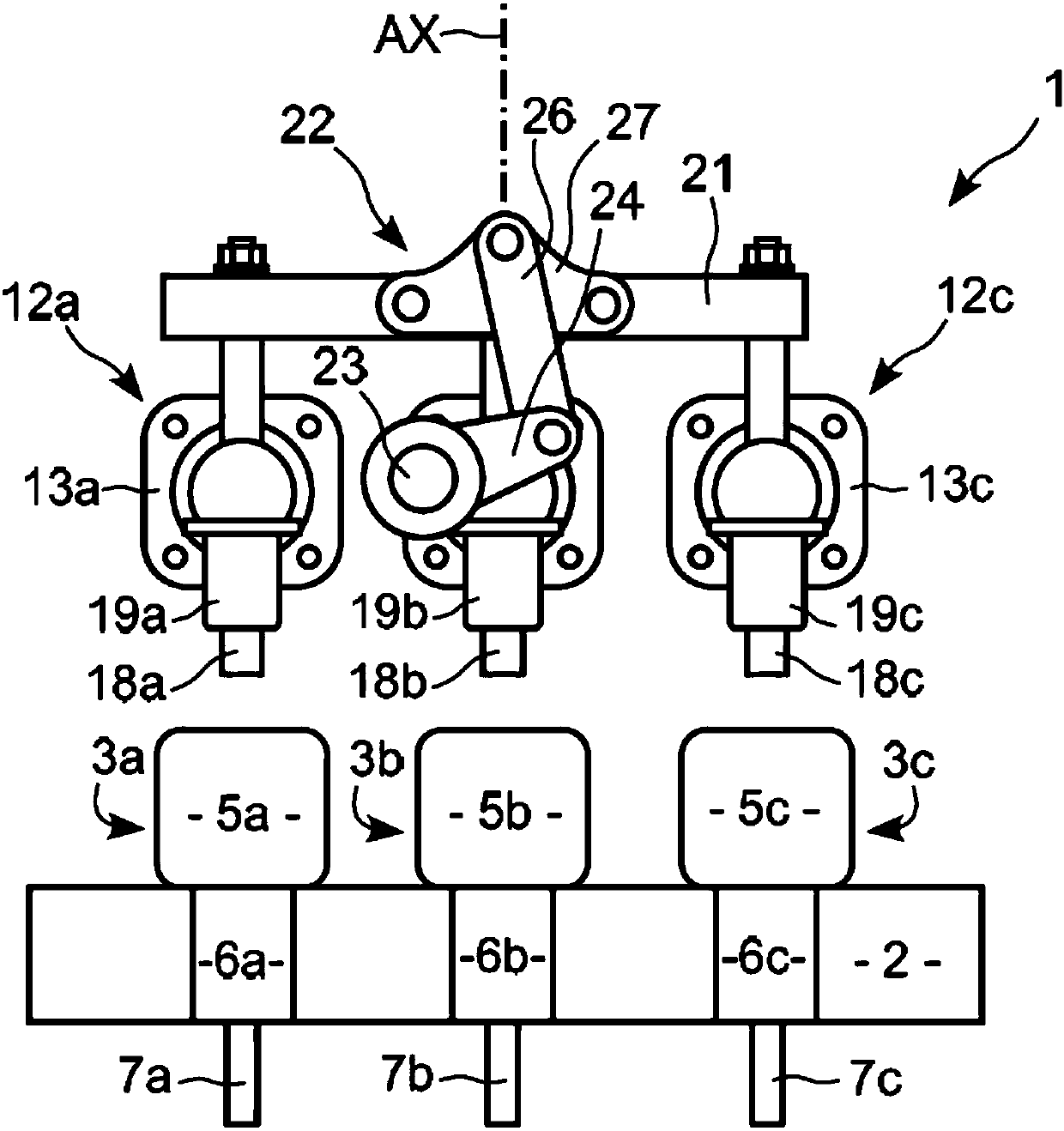

[0028] figure 1 The shown electrical earthing switch 1 according to the invention comprises a main insulating plate 2 which is substantially circular and carries three line contacts 3a, 3b, 3c. The example in the figures is a three-phase electrical grounding switch, but the invention is also applicable to single-phase or other types of multi-phase grounding switches.

[0029] The earthing switch 1 comprises three corresponding earthing contacts 4a, 4b, 4c, which are located in the switch such as figure 1 with figure 2 When closed as shown, it can make contact with the corresponding line contact 3a, 3b, 3c, or in the switch such as image 3 Disconnection is possible from these line contacts when open as shown.

[0030] In the following, the first line contact 3a and the first ground contact 4a will be described in more detail, their components and parts having reference symbols suffixed by the letter "a". Since the second and third contacts have the same part as the assembly,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap