Injection-mold conveying mechanism with exhaust gas shield

A conveying mechanism and finished product technology, which is applied in the field of plastic processing, can solve the problems of physical injury, severe human injury, and hair loss of workers, and achieve the effects of reducing work intensity, reducing air pollution, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

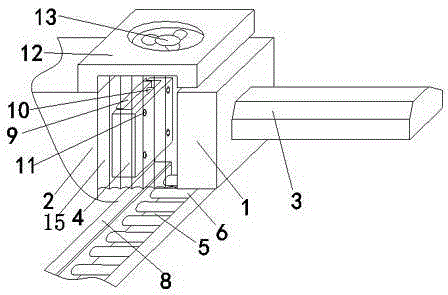

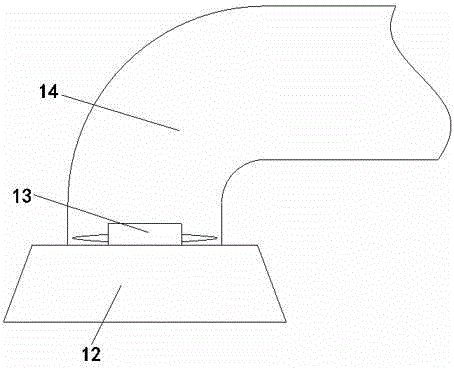

[0017] Such as figure 1 Shown is a schematic structural view of the injection molding product delivery mechanism provided with exhaust gas protection in the present invention; an injection molding product delivery mechanism provided with exhaust gas protection in the present invention includes an injection molding machine base, a fixed frame 2 arranged on the base and a movable Frame 1, described fixed frame 2 is provided with left mold 4, and described movable frame 1 is provided with the right mold that forms mold cavity with left mold, and described left mold 4 is provided with demoulding device and is used for fixing The mounting hole of the plastic product, the left mold 4 is provided with a track below, and the track 5 extends out of the machine base, and the track 5 includes mounting seats 8 arranged on both sides and transport rollers ar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap