Gas-liquid separation mechanism capable of monitoring gas concentration

A gas-liquid separation and gas concentration technology, applied in the preparation of test samples, etc., can solve the problems of affecting the gas concentration efficiency in the detection liquid, cumbersome separation process, complex structure, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

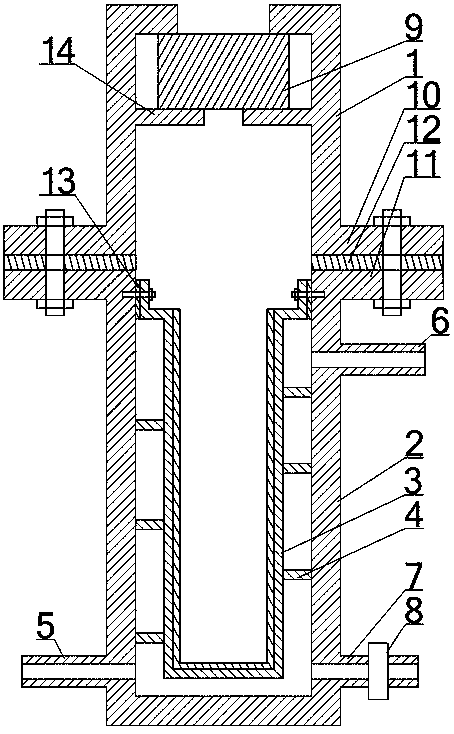

[0018] Such as figure 1 As shown, the gas-liquid separation mechanism that can monitor the gas concentration includes an upper shell 1, a lower shell 2, and a gas-liquid filter diaphragm 3, wherein the upper shell 1 forms a drum shape with an open lower end, and the lower shell 2 forms an upper end. Open barrel shape, the upper end of the lower housing 2 is sealed and connected with the lower end of the upper housing 1 , the gas-liquid filter membrane 3 is arranged in the lower housing 2 , and its upper end is sealed and connected with the inner wall of the lower housing 2 . A gas cavity is formed between the upper shell 1, the lower shell 2, and the gas-liquid filter diaphragm 3, and a transition chamber is formed between the lower shell 2 and the gas-liquid filter diaphragm 3. The upper and lower sides of the lower shell 2 A liquid outlet pipe 6 and a liquid inlet pipe 5 are respectively arranged on the wall, and both the liquid outlet pipe 6 and the liquid inlet pipe 5 are con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap