Coupling pin disassembling tool for engine test bed

A technology for test benches and dismantling tools, which is applied in the field of mechanical tools, can solve problems such as the difficulty of fixing the head of a wheel pin, and achieve the effects of simple production, convenient use, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments.

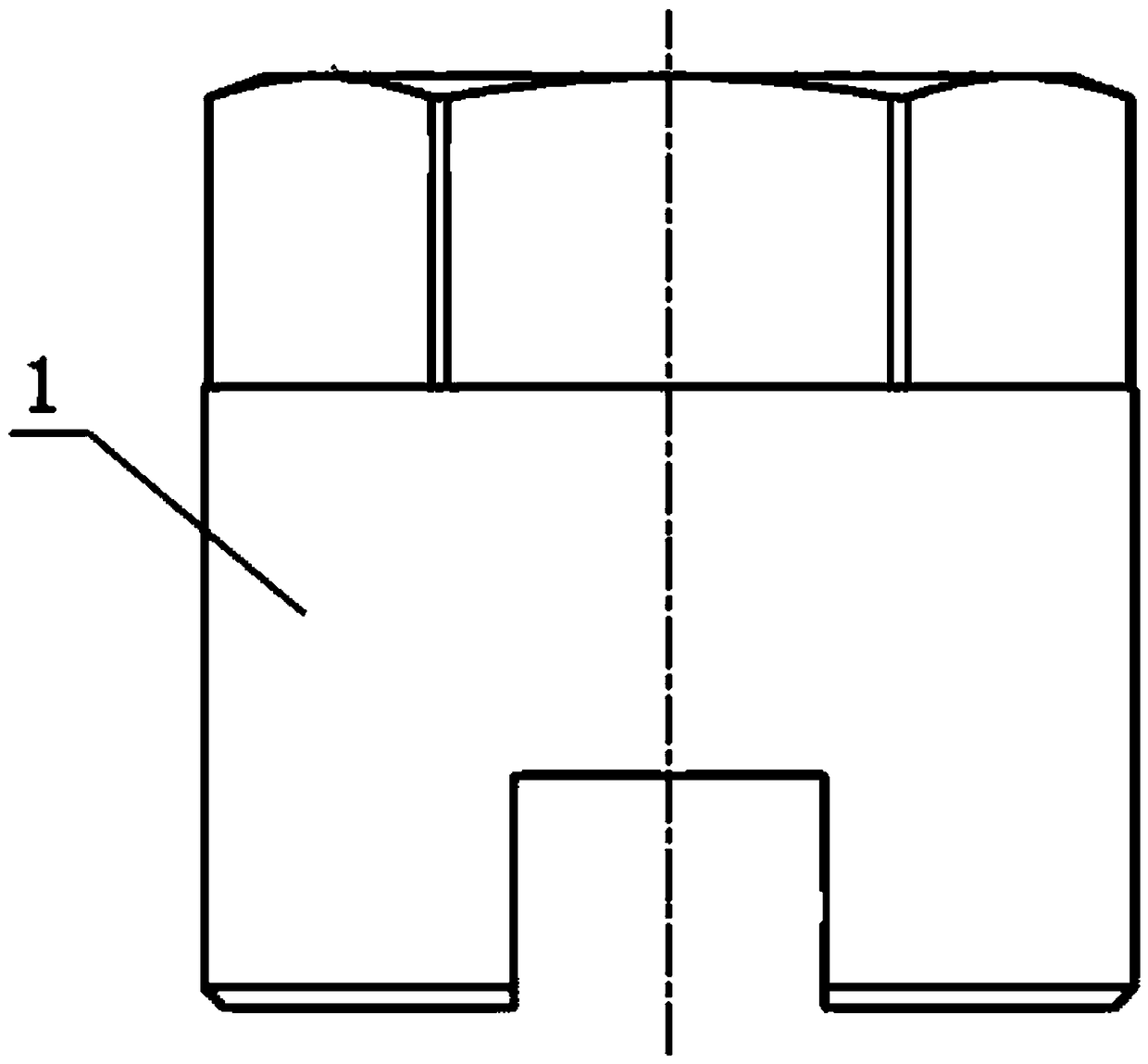

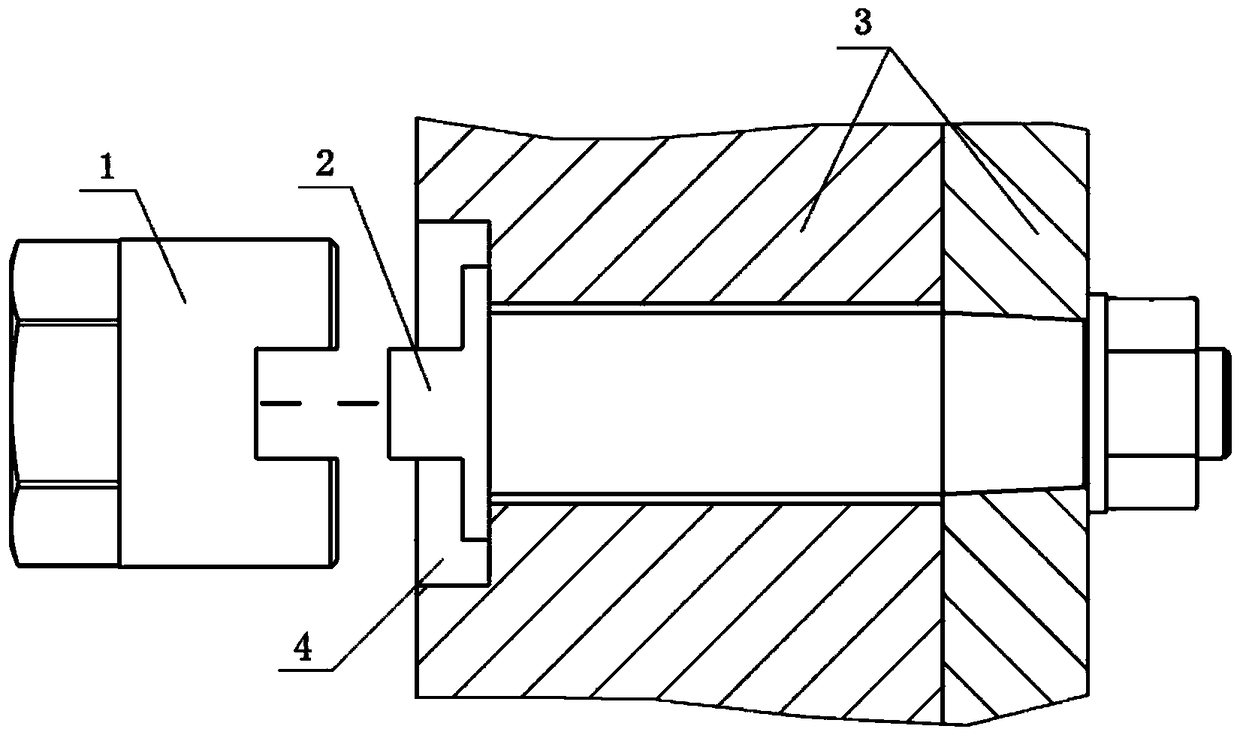

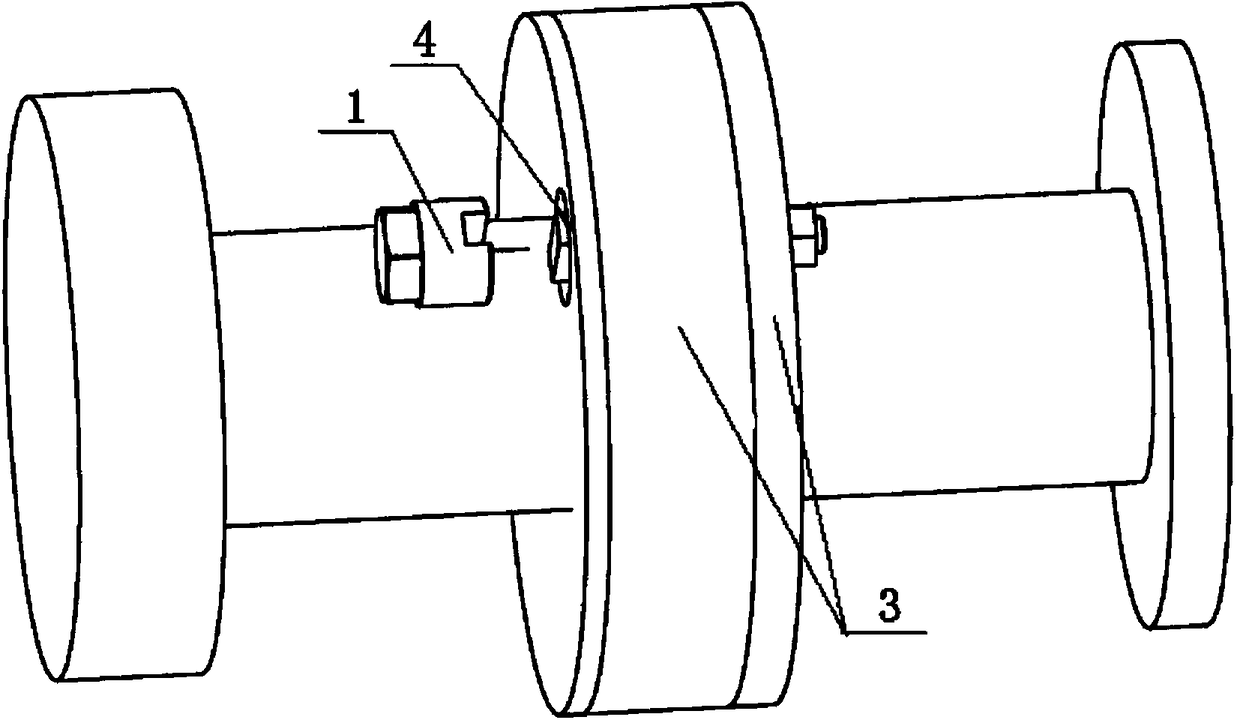

[0011] The tool for dismantling the wheel pin of the engine test stand has the following structure: the dismantling tool 1 is a cylinder, the upper end of the cylinder is a hexagonal nut, and the lower end of the cylinder is provided with a through groove. The groove width of the through groove is greater than the thickness of the wheel pin cap 2 by 1mm; the groove depth of the through groove is greater than the height of the wheel pin cap by 1mm; the outer diameter of the removal tool cylinder is smaller than the inner diameter of the pin perforation 4 in the wheel set of the test bench 1mm .

[0012] When it is necessary to dock or disassemble the wheel set in the engine test bench, insert the front end of the removal tool into the pin hole in the wheel set. Then use a wrench to fix the wheel pin, and finally use another wrench

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap