Long-service-life composite bearing for combustion gas turbine

A technology of composite bearings and gas turbines, which is applied in the direction of rotating combined bearings, bearings, bearing components, etc., can solve the problems of unfavorable lubricating oil film formation, shortening the service life of bearings, vibration and noise, etc., achieve a wide and stable working range, and improve bearing load capacity ability, the effect of reducing the starting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

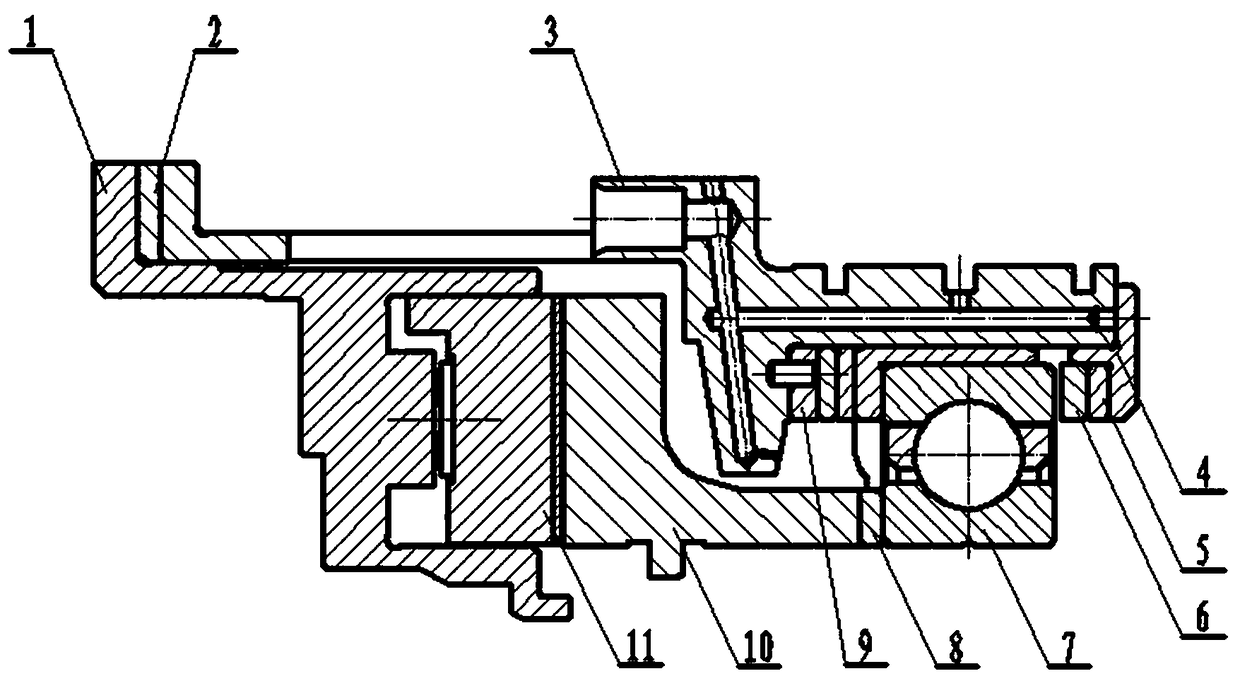

[0009] refer to figure 1 , a long-life composite bearing for a gas turbine, comprising a ball bearing 7 and a thrust bearing, the thrust bearing comprising a thrust bearing pad 11 and a thrust bearing disk 10 installed on a thrust bearing housing 1, the average thickness of the oil film of the thrust bearing passing through the first An adjusting ring 2 is adjusted to adjust the working load of the thrust bearing; the ball bearing 7 is installed on the ball bearing seat 3, and the ball bearing seat 3 is provided with a main elastic ring 9 and an auxiliary elastic ring 6, and the ball bearing 7 and the main elastic ring 9 cooperates with the auxiliary elastic ring 6, and the pre-deformation of the main elastic ring 9 and the auxiliary elastic ring 6 is adjusted and fixed through the second adjustment ring 5 and the stop ring 4, so as to adjust the maximum working load borne by the ball bearing 7, that is, to stabilize Working load; the safety clearance of the ball bearing seat 3 o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap