Pneumatic tire

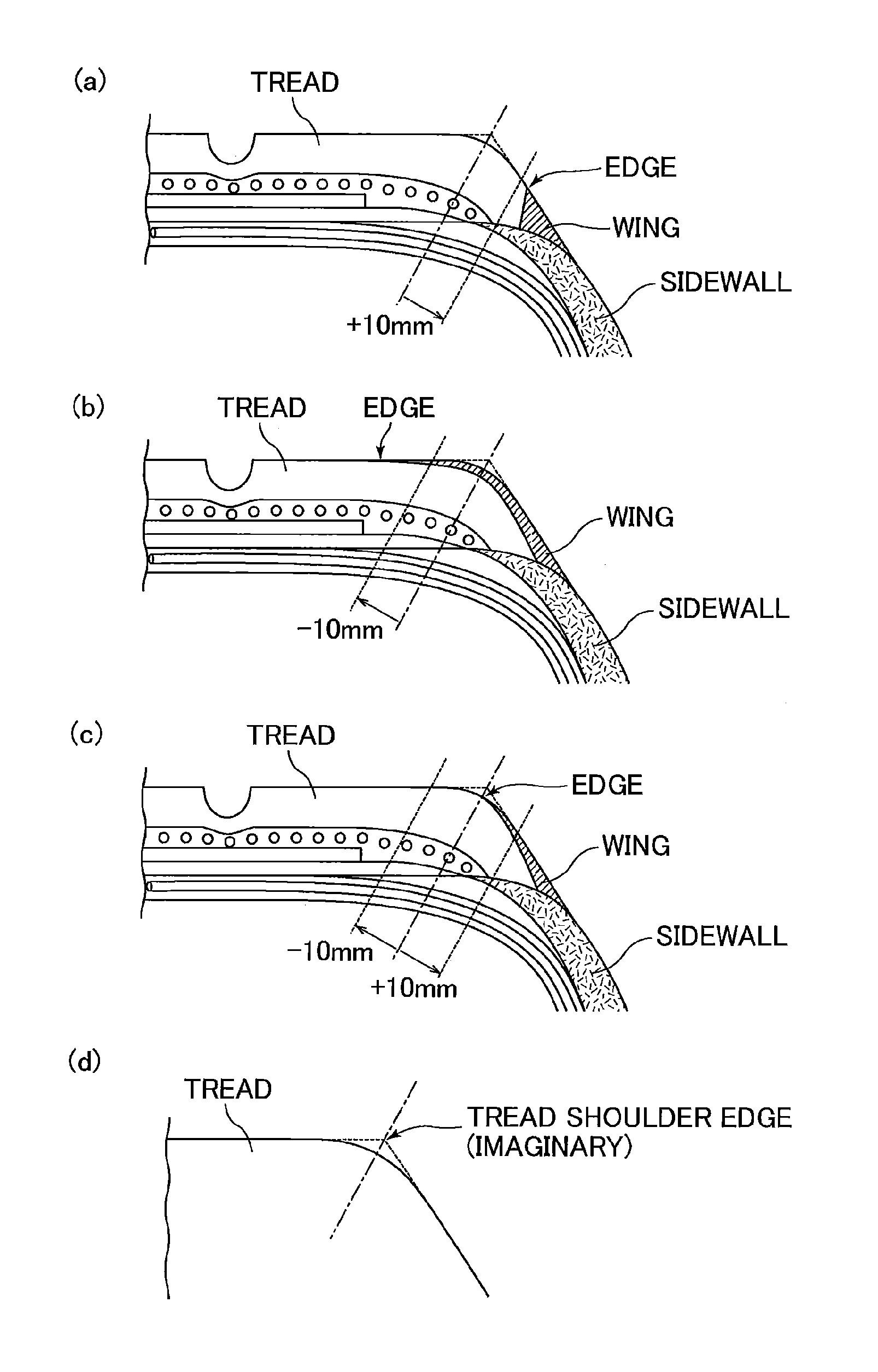

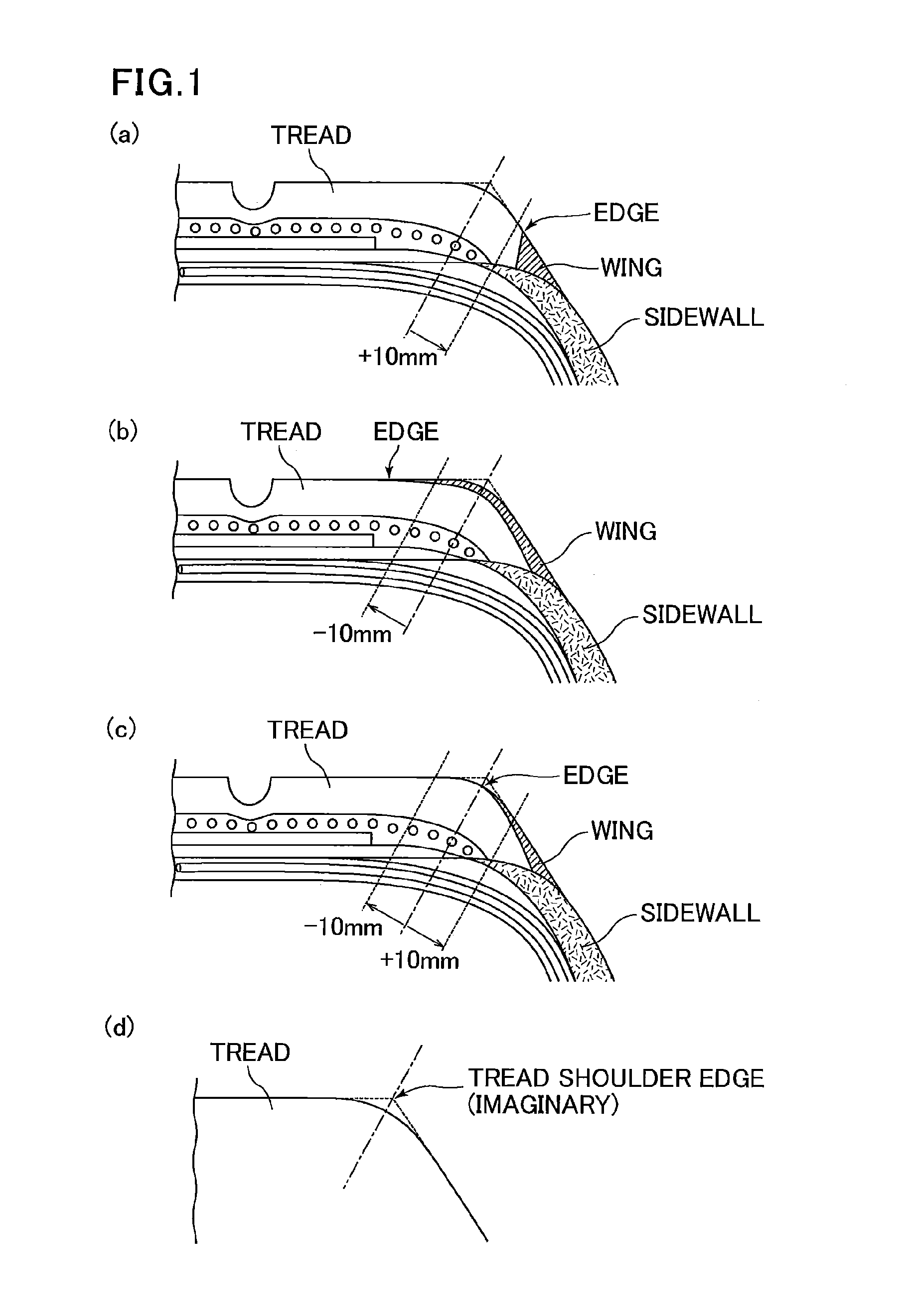

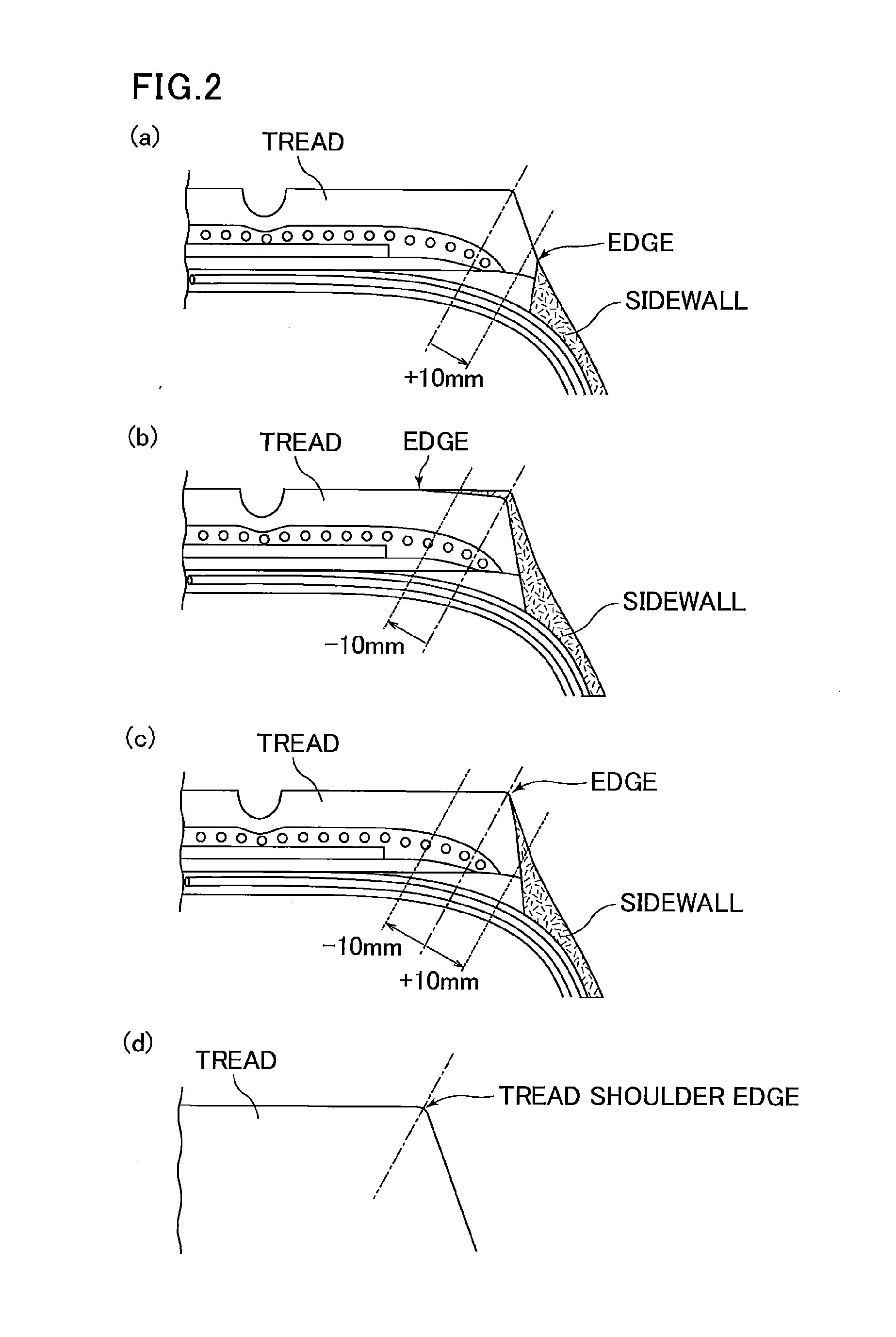

a pneumatic tire and tire body technology, applied in the field of pneumatic tires, can solve the problems of peeling, curling, peeling, and the finish bonding surface between the tread and its adjacent wing or sidewall after vulcanization is sometimes in poor condition, and achieves excellent finish bonding surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0061]The present invention is more specifically described with reference to examples of tires for passenger vehicles with a TOS structure, but the present invention is not limited to these examples.

Preparation of Terminal Modifier

[0062]A measuring flask (100-mL) was charged with 23.6 g of 3-(N,N-dimethylamino)propyltrimethoxysilane (AZmax. Co.) in a nitrogen atmosphere, and was further charged with anhydrous hexane (Kanto Chemical Co., Inc.) to thereby prepare a terminal modifier in a total amount of 100 mL.

Copolymer Preparation 1

[0063]A sufficiently nitrogen-purged, pressure-resistant vessel (30-L) was charged with 18 L of n-hexane (Kanto Chemical Co., Inc.), 2000 g of butadiene (Takachiho Trading Co., Ltd.), and 2 mmol of tetramethylethylenediamine (Kanto Chemical Co., Inc.), and then the temperature was raised to 60° C. Next, 10.3 mL of butyllithium (Kanto Chemical Co., Inc.) was added to the mixture, and then the temperature was raised to 50° C., followed by stirring for three hou

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap