Valve rod of acting valve

A technology of actuating valve and valve stem, which is applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of high processing difficulty, complex valve stem structure, unstable action time, etc., and achieves low design difficulty, simple structure, Easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] In the following description, the clockwise and counterclockwise rotations are viewed from left to right.

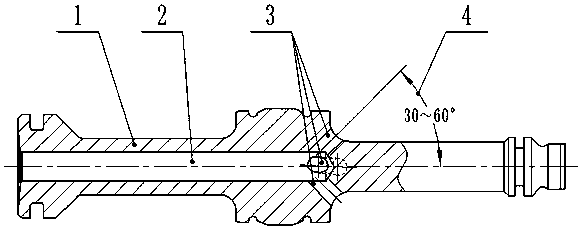

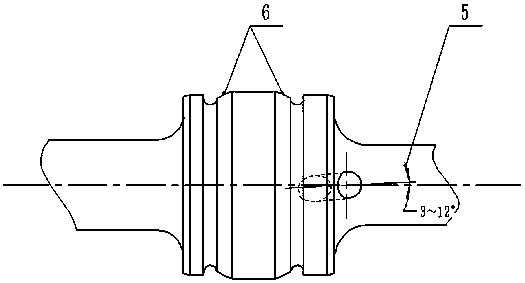

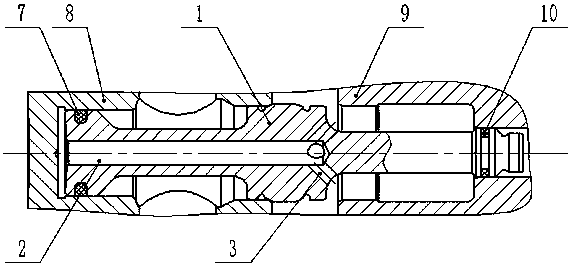

[0019] figure 1 , 2 In the center position of one end of the valve stem body 1, a deep hole coaxial with the valve stem is opened as the oil passage 2, and its outlet is 4 compound angle oil holes 3. The 4 compound angle oil holes 3 should be uniformly distributed in the axial direction. The total cross-sectional area should be approximately equal to the cross-sectional area of the oil passage. The axis of a single composite hole should form an angle -4 with the axis of the oil passage in the Y direction, and the angle -4 should be 30°-60°, and intersect at a point on the axis of the oil passage. The axis of the oil passage should be at the axis of the oil passage. There is an included angle of 2 in the X direction, which should be 3°-12°. The valve stem body 1 has a sealing surface, and the sealing surface is a spherical sealing surface 6 for sealing with the valve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap