Environmental greening mountain slope tree planting conveyor

A conveyor and hillside technology, applied in the field of environmental greening hillside tree planting conveyors, can solve the problems of reducing the efficiency of planting trees, easy to transport trees, and increased labor, etc., to increase the distance of conveying, reduce labor, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

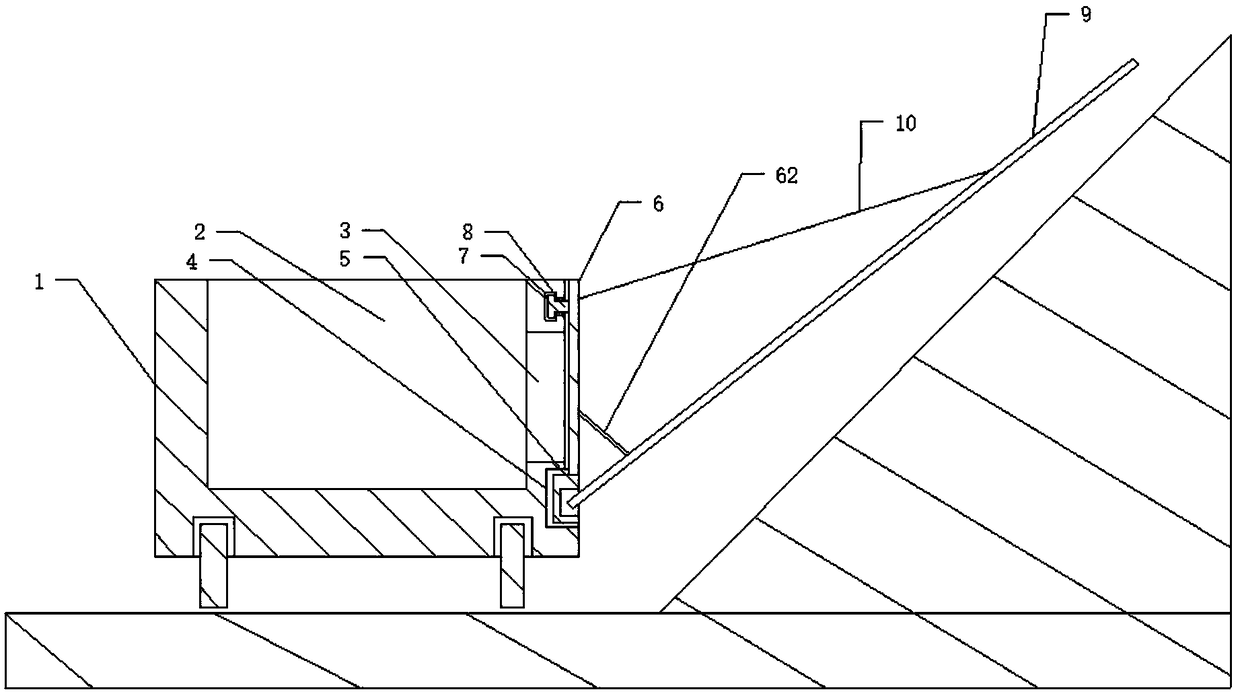

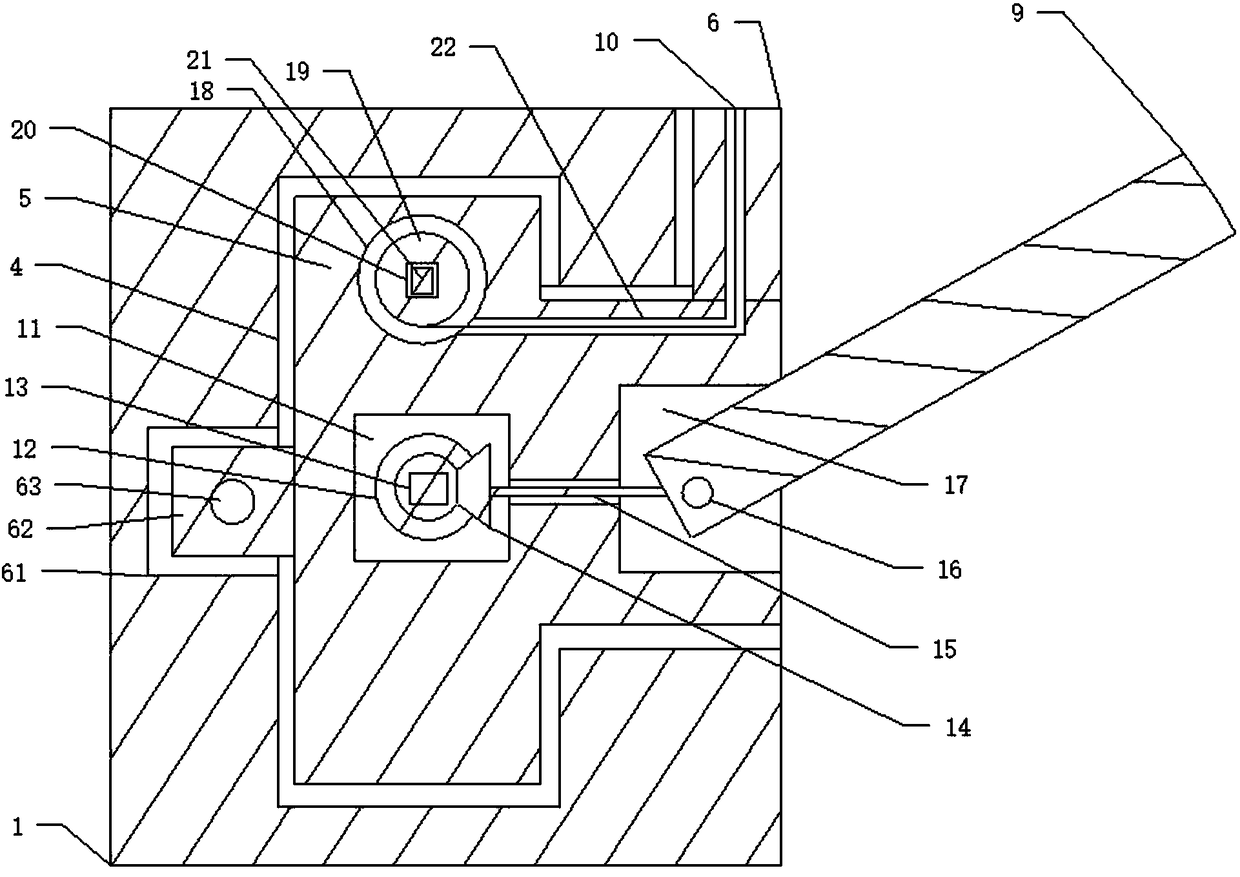

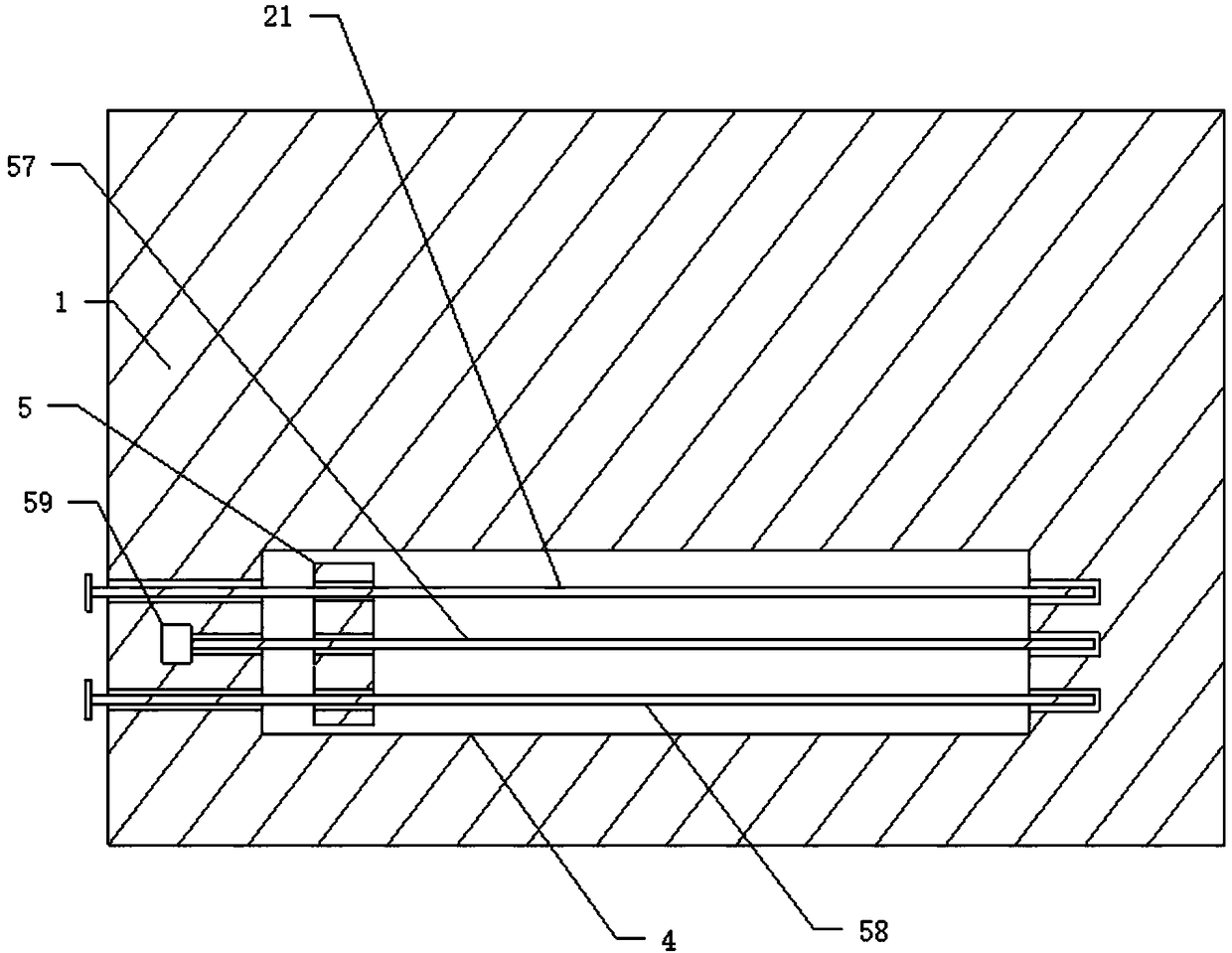

[0028] Such as Figure 1 to Figure 7 Shown, a kind of environmental greening hillside tree planting conveyor comprises a carriage body 1, and said carriage body 1 is provided with rotating wheels, and said carriage body 1 is provided with a compartment inner groove 2, and said carriage body One side of the car body 1 is provided with a car body outlet 3 corresponding to the tank 2 in the car body, and a first chute 4 is provided on one side of the car body 1, and a first chute 4 is set in the first chute 4 There is a sliding first slider 5, on which a rotating first conveying frame 9 is arranged, and on the first conveying frame 9, a first conveying groove that is provided in a concave shape is provided 36. Two ends of the first conveying frame 9 are respectively provided with two eighth rotating shafts 32 and tenth rotating shafts 43 rotating in the first conveying groove 36, and the eighth rotating shaft 32 and the tenth rotating shaft A first driving runner 33 is respectively

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap