Displacement adjusting device for H-shaped steel support and construction method thereof

A displacement adjustment and construction method technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of large steel support deflection and steel support instability, and achieve the effect of maintaining stability and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

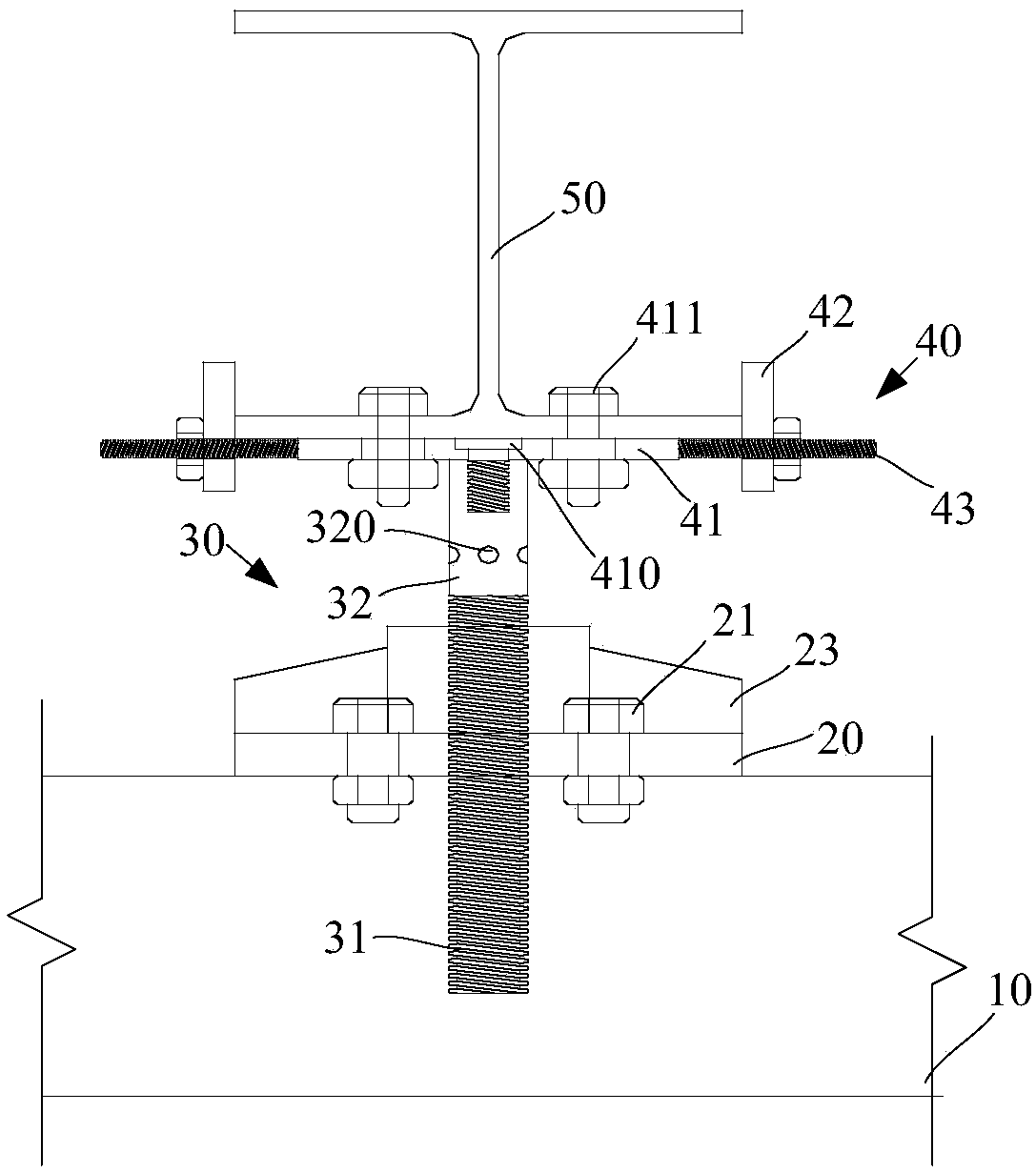

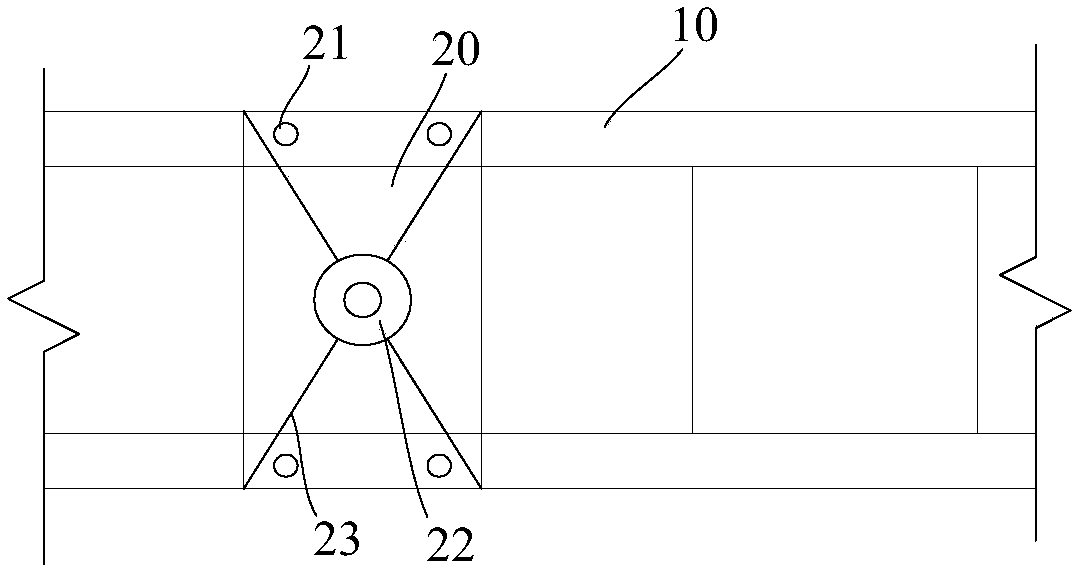

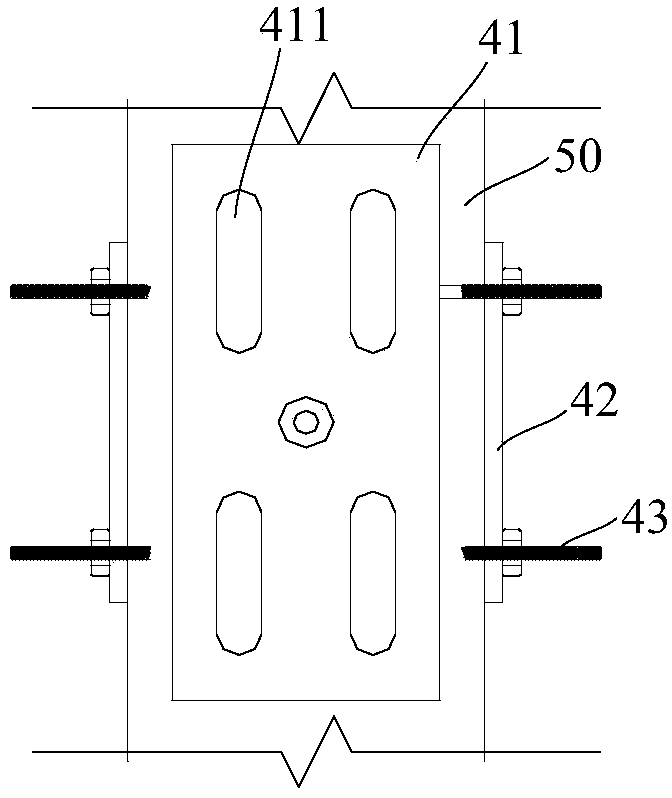

[0052] refer to figure 1 , shows a schematic structural view of the displacement adjustment device for H-shaped steel supports of the present invention. Such as figure 1 As shown, the displacement adjustment device for H-shaped steel support of the present invention includes: a base 20 detachably fixed on the joist 10; an adjustment rod 30 inserted vertically and screwed to the base 20; detachably fixed on the adjustment The support structure 40 at the top of the rod 30; and a plurality of clamping structures located on the opposite sides of the support structure 40 for clamping the H-shaped steel support, the clamping distance of the clamping structure is adjustable; Move up and down inside to adjust the distance between the H-shaped steel support and the joist to ensure that the H-shaped steel support is always in a straight state.

[0053] A

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap