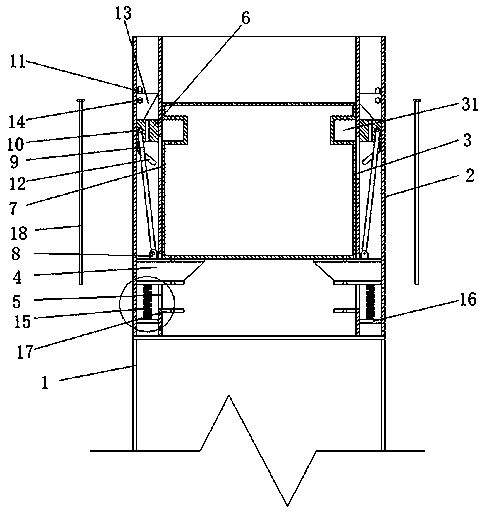

Connecting structure between steel column and high-rise truss beam

A technology for connecting structures and truss beams, which is applied in the direction of building construction and construction, can solve the problems of inability to achieve effective fixation and low connection strength of nodes, and achieve the effect of simple installation structure and improved connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

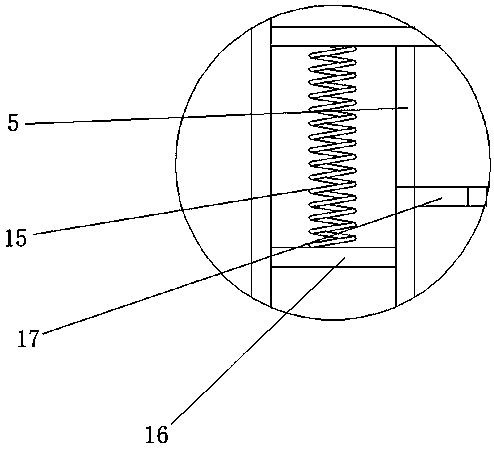

[0014] see Figure 1-2 , this specific embodiment is realized by adopting the following technical scheme, which includes a steel column 1, and the two ends of the upper top surface of the steel column 1 respectively extend vertically upwards to a positioning seat 2, and a positioning seat 2 is arranged between the two positioning seats 2. butt truss beam 3;

[0015] The positioning seat 2 is a hollow square tubular structure as a whole, and an inner armpit beam 4 is arranged inside the positioning seat 2, and one end of the inner armpit beam 4 passes through the inner surface of the positioning seat 2 and extends to two Between the positioni

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap