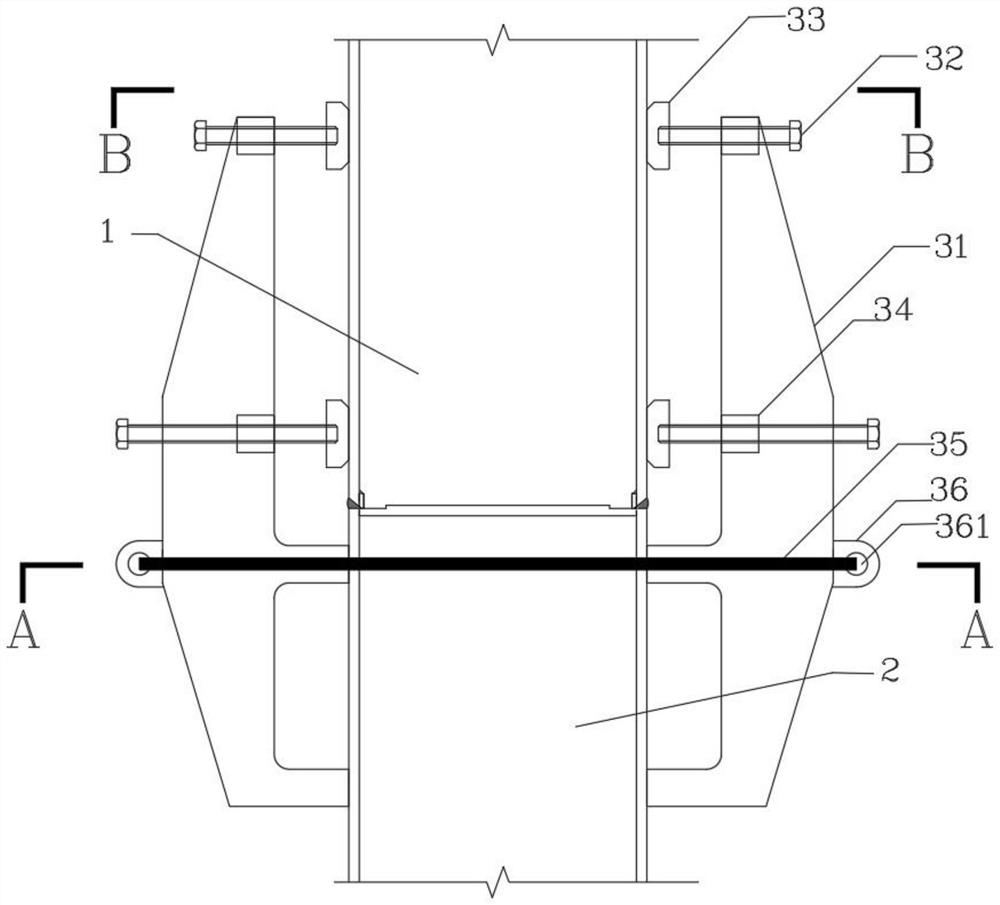

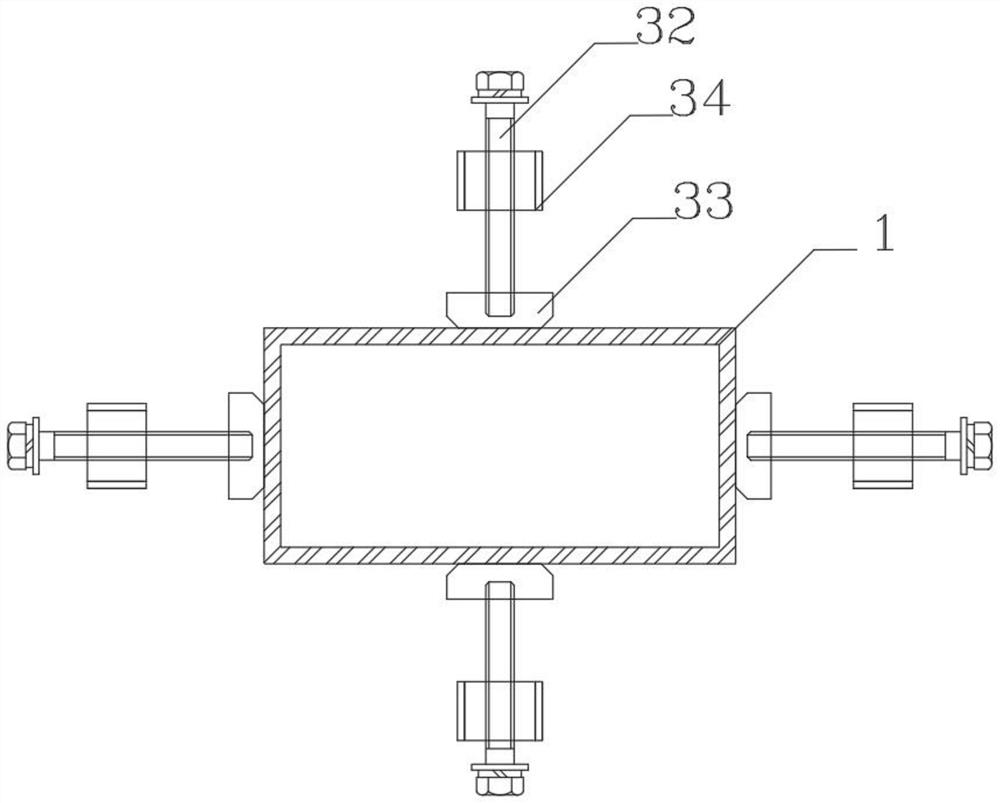

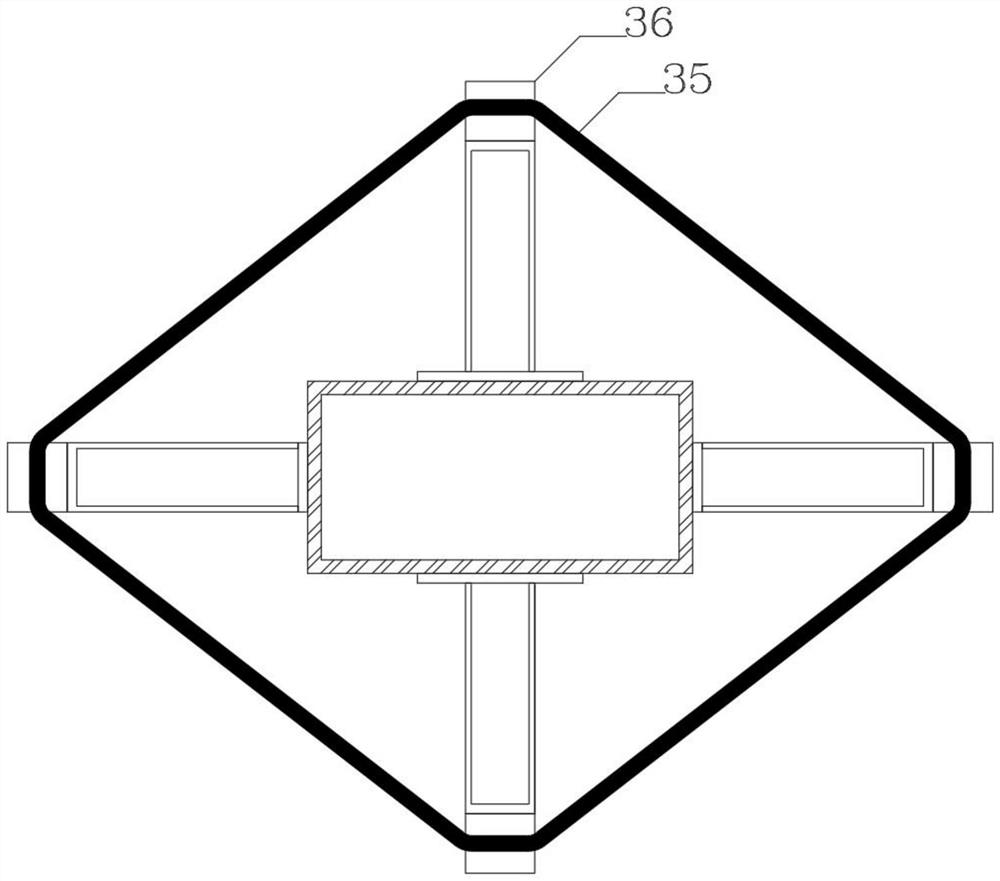

Steel column construction site splicing installation positioner

A locator and steel column technology, which is applied in the direction of construction and building construction, can solve the problems of weak corrosion resistance, labor and materials, etc., and achieve the effects of simplified processing, convenient and accurate installation and positioning, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description is presented to enable any person skilled in the art to make and use the invention and to integrate it into a specific application context. Various modifications, and various uses in different applications will be readily apparent to those skilled in the art, and the generic principles defined herein may be applied to a wider range of embodiments. Thus, the present invention is not limited to the embodiments set forth herein, but is to be accorded the widest scope consistent with the principles and novel features disclosed herein.

[0021] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be apparent to those skilled in the art that the practice of the present invention may not necessarily be limited to these specific details. In other words, well-known structures and devices are shown in block diagram form without detail in order

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap