Metal ion guiding carboxylic acid ligand functionalized polyacid compound, preparation method thereof and application of catalytic degradation chemical warfare agent simulant

A metal ion, catalytic degradation technology, applied in the field of catalytic chemistry, can solve the problems of low catalytic efficiency, difficult to reuse the catalyst, low selectivity, etc., to achieve the reduction of reaction conversion rate and selectivity, the same catalytic effect, and safe operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

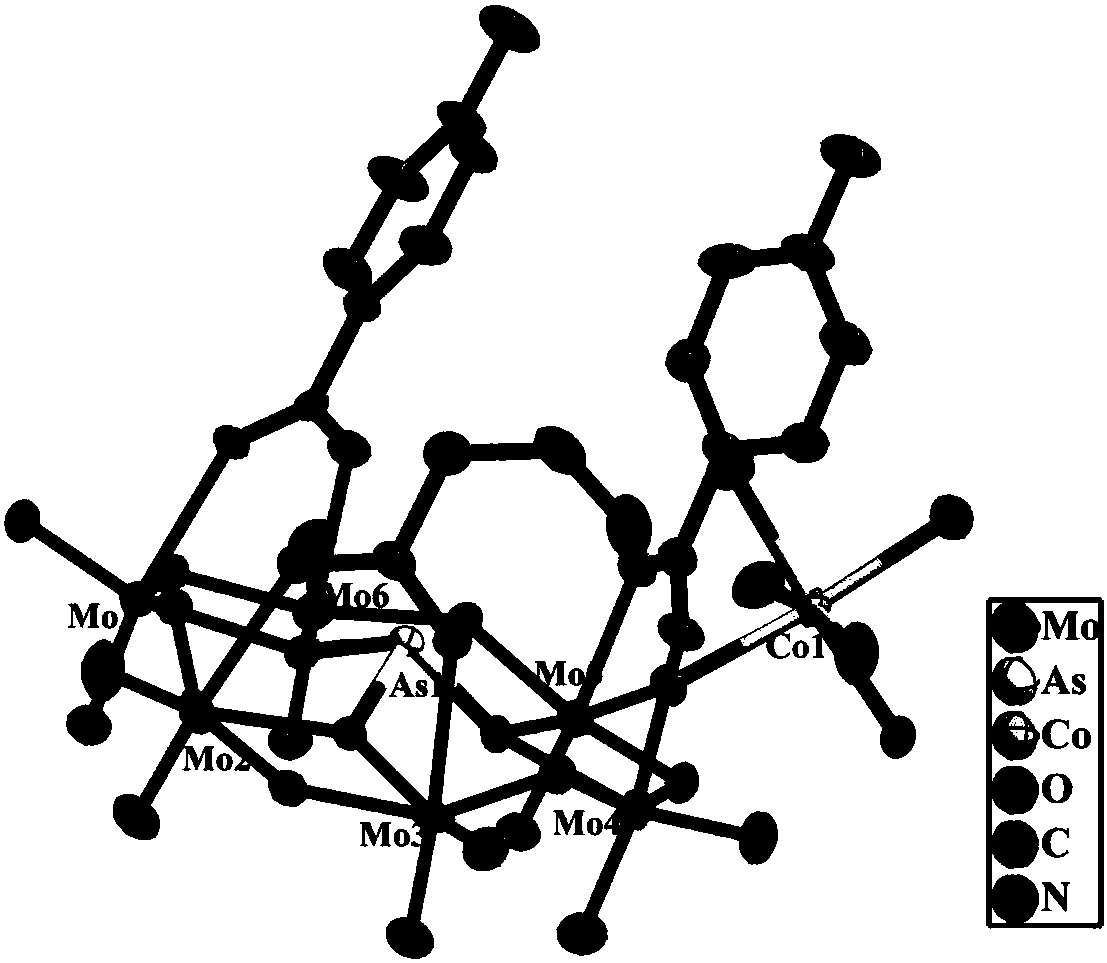

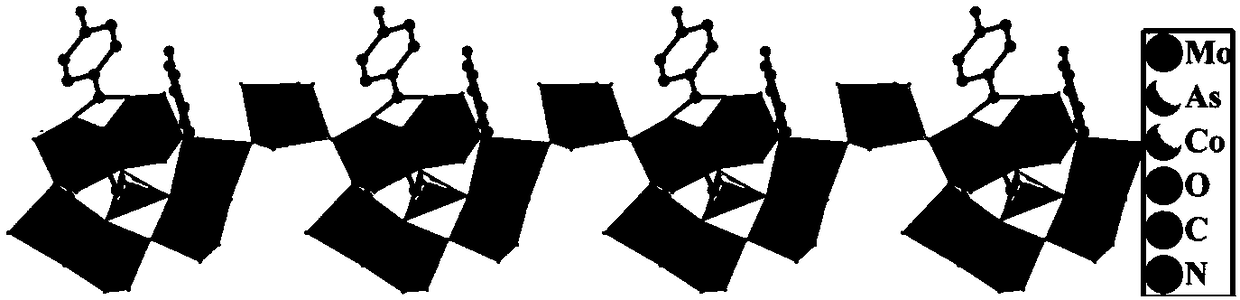

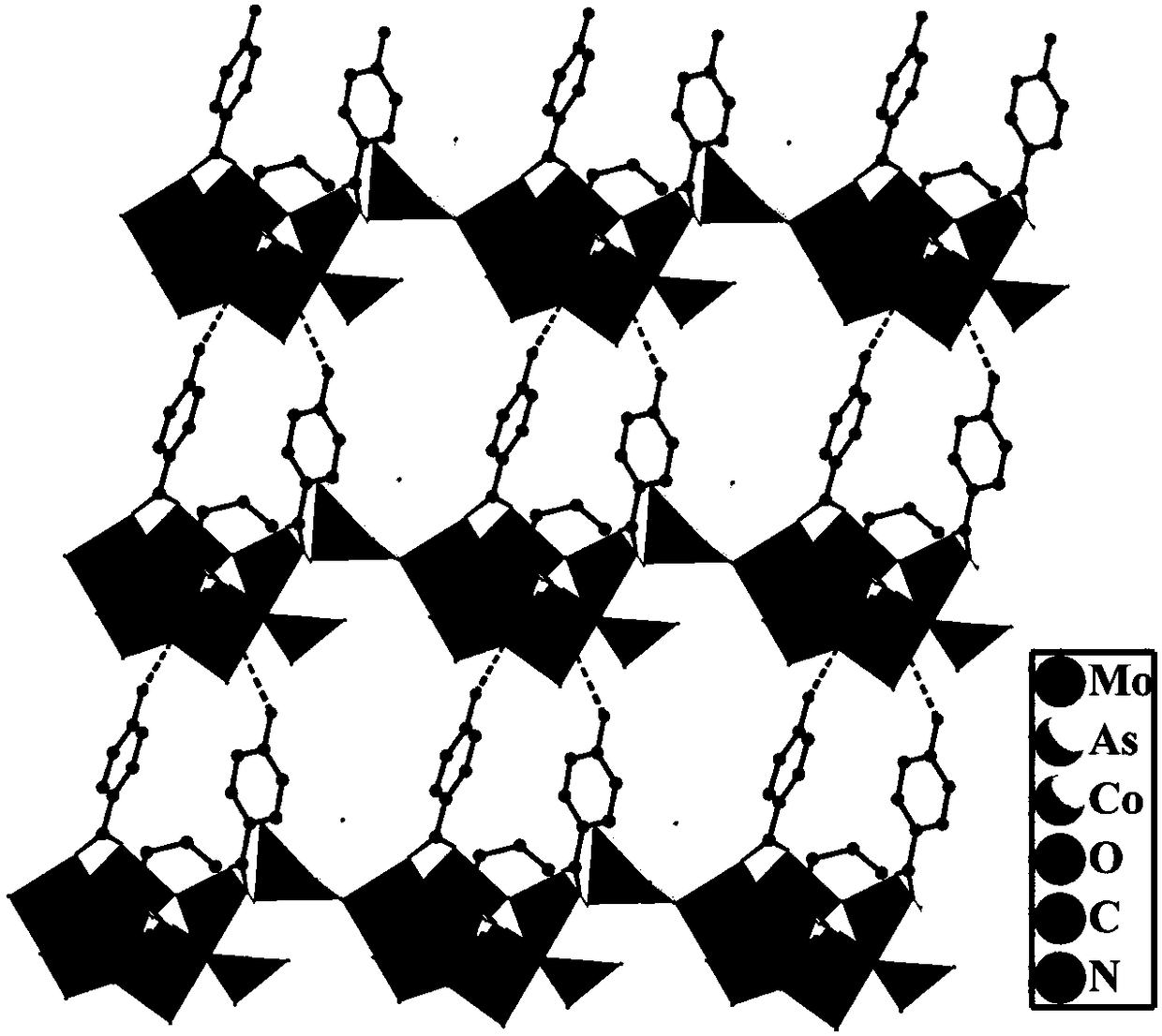

[0040] Example 1 Preparation of metal ion-guided carboxylic acid ligand functionalized polyacid hybrid compound catalyst, the specific steps are as follows:

[0041] Dissolve 0.145g sodium molybdate, 0.0197g arsenic dioxide, 0.0224g potassium chloride, 0.0089g alanine and 0.0274g p-hydroxybenzoic acid in 20mL water and stir, adjust the PH=3.5 with HCl, and then stir at room temperature 1 After hours, add 0.0714g of cobalt chloride, finally reflux at 80°C for one hour, and cool to obtain the desired compound.

[0042] The 0.0714g cobalt chloride is replaced by 0.0678g nickel chloride, 0.0861g zinc chloride or 0.0486g manganese chloride.

Example Embodiment

[0043] Example 2 Preparation of metal ion-guided carboxylic acid ligand functionalized polyacid hybrid compound catalyst, the specific steps are as follows:

[0044] Dissolve 0.145g sodium molybdate, 0.0197g arsenic dioxide, 0.0224g potassium chloride, 0.0089g alanine and 0.0274g p-hydroxybenzoic acid in 20mL water and stir, adjust the PH=3.5 with HCl, and then stir at room temperature 1 Then add 0.0873g nickel nitrate, and finally reflux at 80°C for one hour, and cool to obtain the desired compound.

Example Embodiment

[0045] Example 3 Preparation of metal ion-guided carboxylic acid ligand functionalized polyacid hybrid compound catalyst, the specific steps are as follows:

[0046] Dissolve 0.145g sodium molybdate, 0.0197g arsenic dioxide, 0.0224g potassium chloride, 0.0089g alanine and 0.0274g p-hydroxybenzoic acid in 20mL water and stir, adjust the PH=3.5 with HCl, and then stir at room temperature 1 Then add 0.0893g zinc nitrate, and finally reflux at 80°C for one hour. Cooling is the preparation of metal ion-guided carboxylic acid ligand functionalized polyacid hybrid compound catalyst in Example 4. The specific steps are as follows:

[0047] Dissolve 0.145g sodium molybdate, 0.0197g arsenic dioxide, 0.0149g potassium chloride, 0.0089g alanine and 0.0274g p-hydroxybenzoic acid in 20mL water and stir, adjust the PH=3.5 with HCl, and then stir at room temperature. Then add 0.0843g cobalt sulfate, finally reflux at 80°C for one hour, and cool to obtain the desired compound.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap