Lubricating system and oil pumping unit comprising lubricating system

A lubricating system and pumping unit technology, which is applied in the direction of lubricating parts, engine lubrication, mechanical equipment, etc., can solve problems such as affecting the lubrication effect, impurities in the return oil, and poor return oil filtration effect, so as to reduce clogging, Reliable lubrication and avoidance of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

[0036] The present invention will be further described in detail below in conjunction with specific embodiments, which should not be understood as limiting the scope of protection claimed by the present invention.

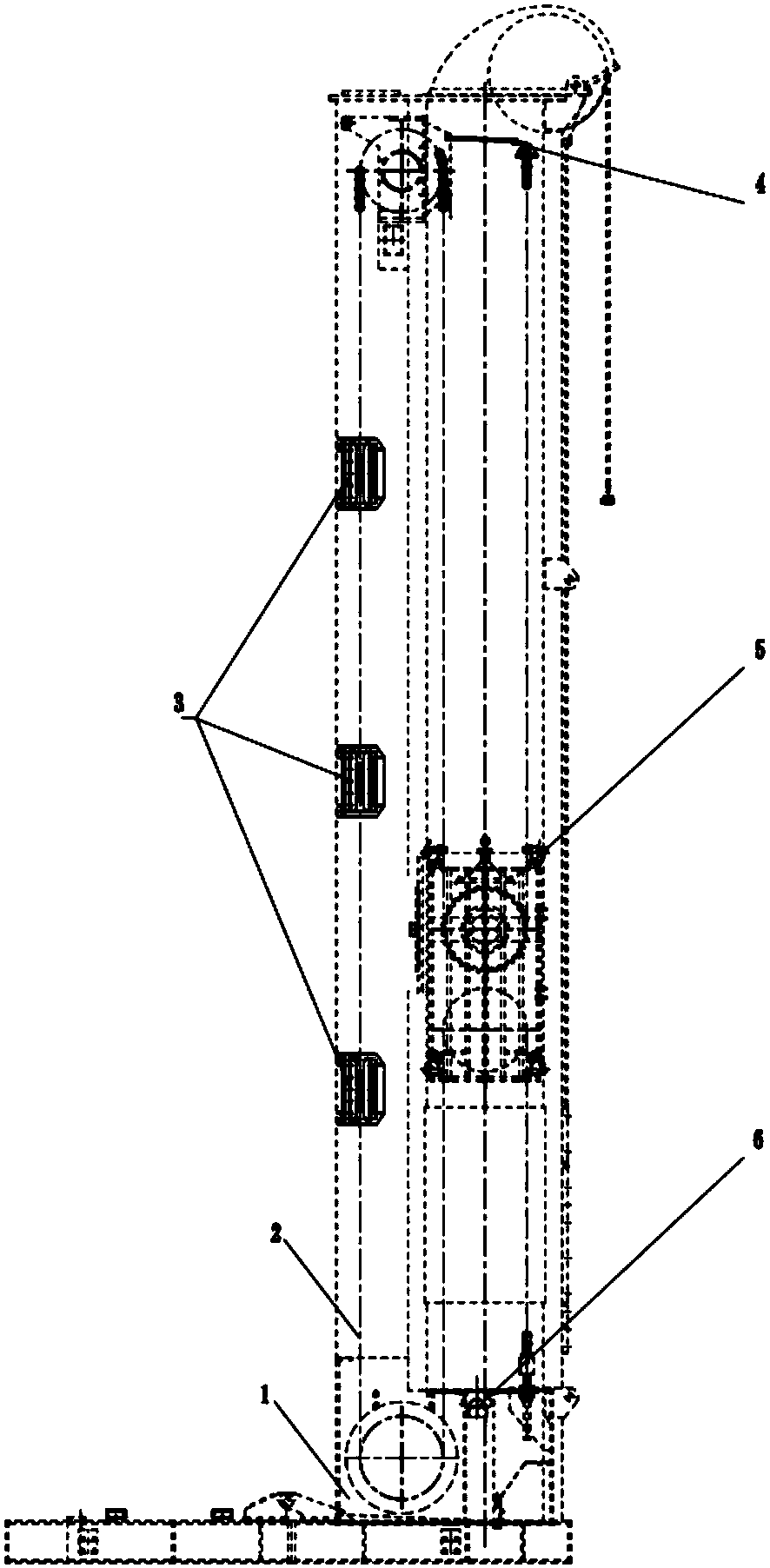

[0037] The pumping unit in the present invention includes a frame, a drive system that provides power for the vertical pumping unit, a control system that controls the drive system, a reducer installed on the frame, a transmission system supported by the frame, and the pumping system. Oil rod suspended heavy load and lubrication system. The working process is as follows: the motor drives the reducer to rotate, the transmission wheel installed on the output shaft of the reduce

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap