Counting device and method for riveting gun

A counting device and riveting gun technology, applied in the field of riveting processing, can solve the problems of easy error, small application range, inability to apply riveting guns, etc., and achieve the effects of convenient installation and maintenance, convenient parameter adjustment, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

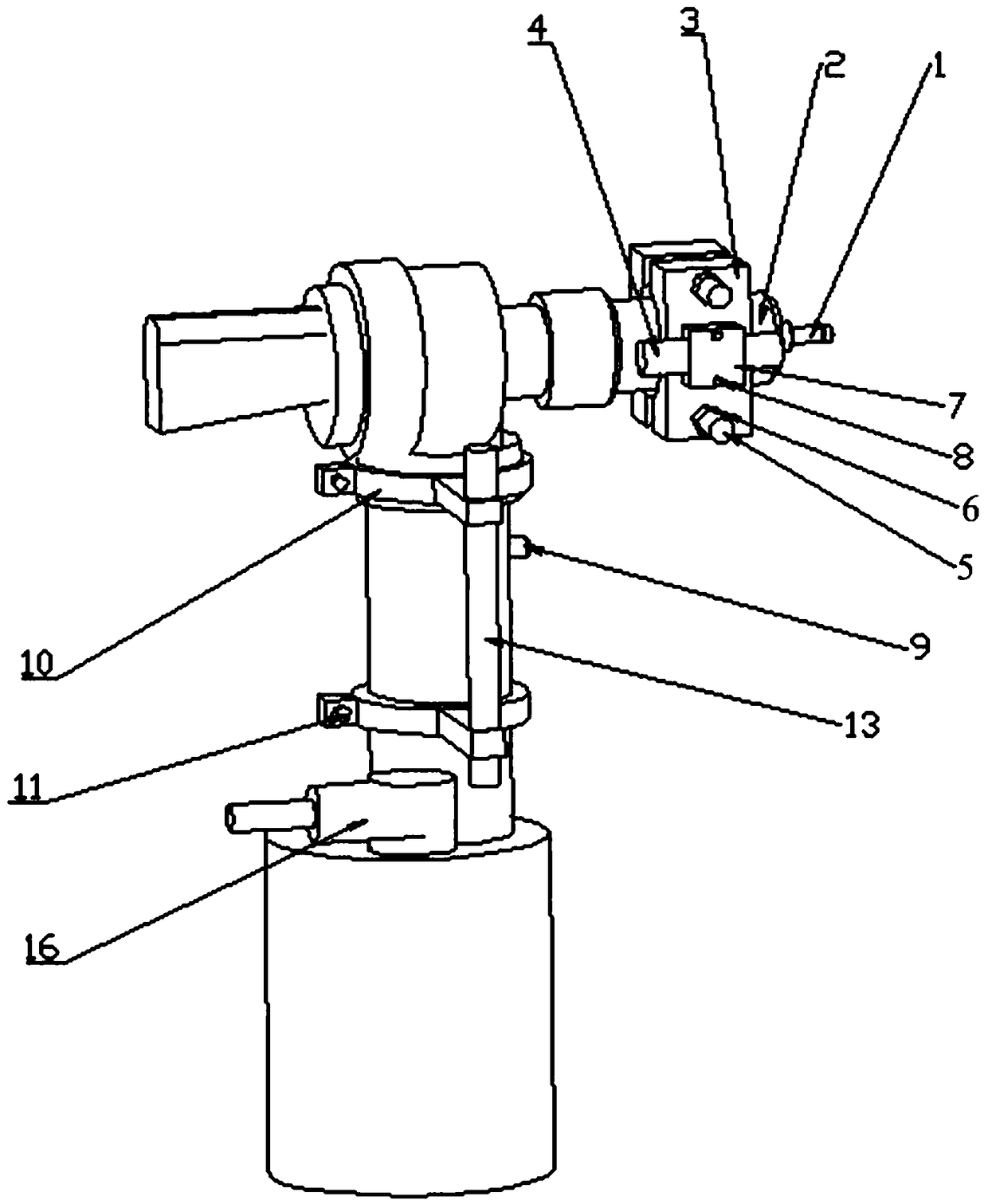

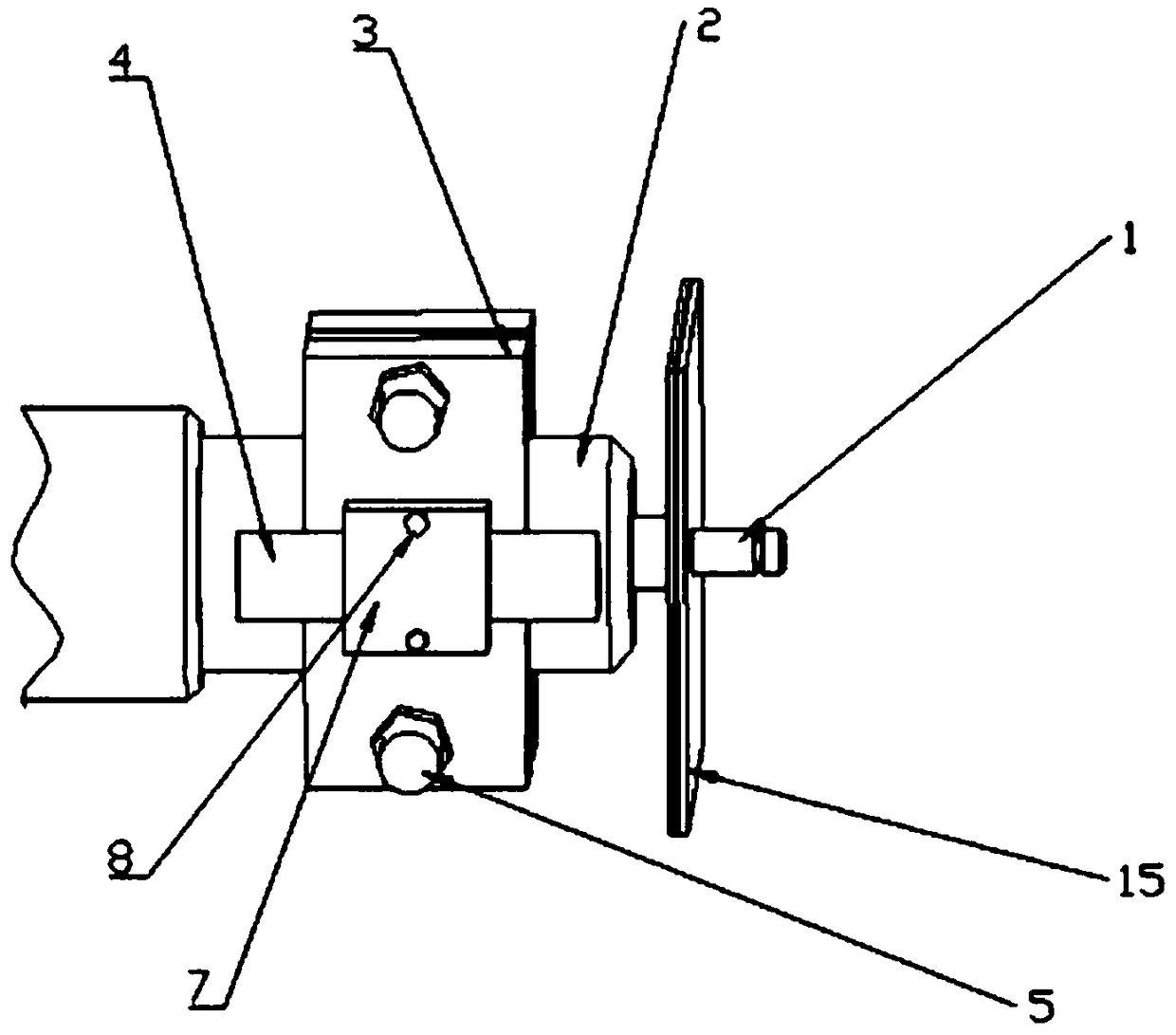

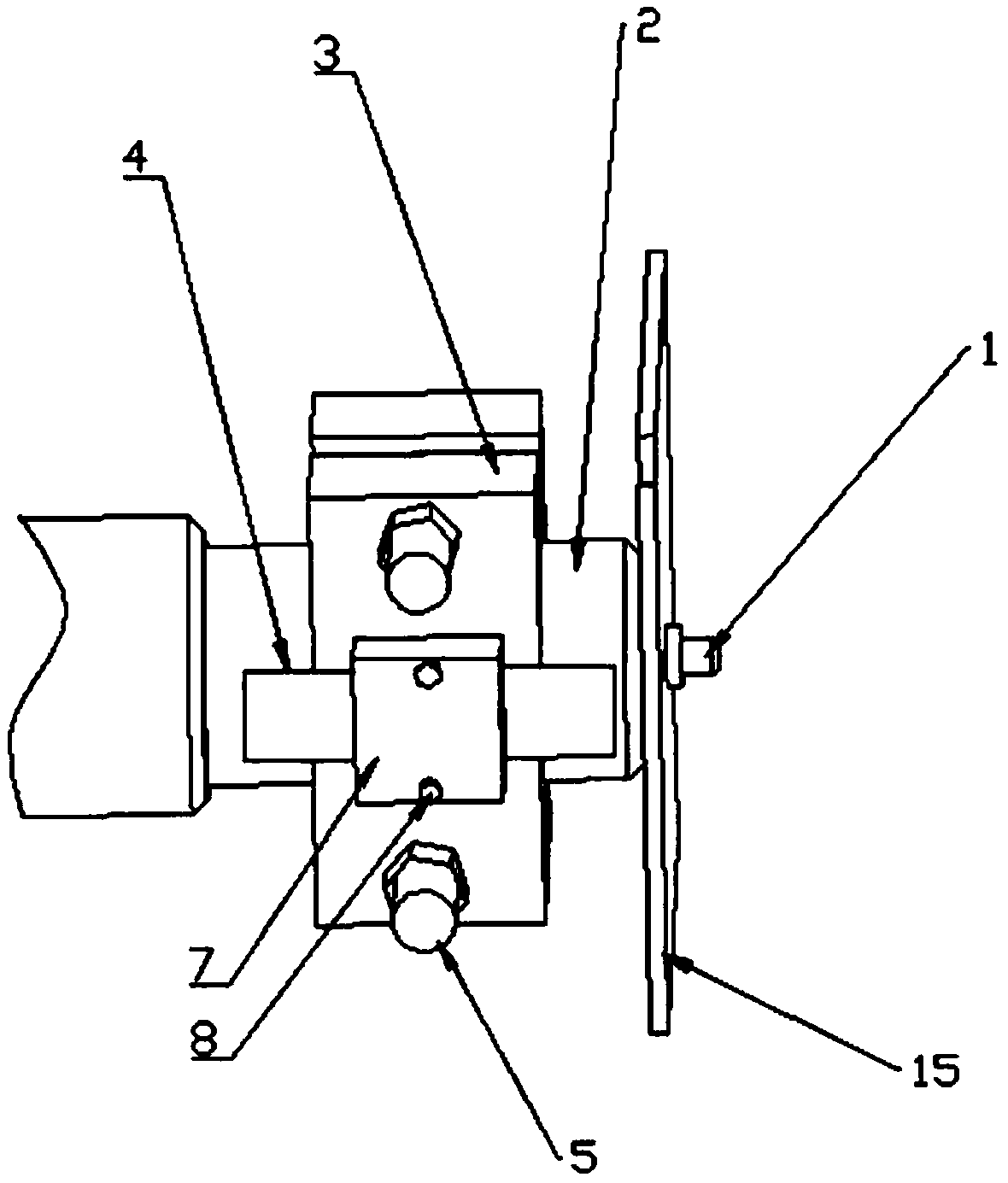

[0041] This embodiment provides a counting device for a riveting gun, including a quantity acquisition device, a signal transmission device, a counting signal comprehensive processing system and a riveting gun control device.

[0042] The counting signal comprehensive processing system is respectively connected with the quantity acquisition device and the riveting gun control device through the signal transmission device. The counting signal comprehensive processing system provides power for the quantity acquisition device, receives the signal transmitted by the quantity acquisition device, and sends a control signal to the control device of the riveting gun.

[0043] The quantity acquisition device is used to transmit signals to the counting signal comprehensive processing system when the riveting gun is riveting the workpiece; the counting signal comprehensive processing system is used to set riveting parameters, receive signals from the quantity acquisition device, count, reset,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap