Domestic garbage pyrolysis reaction furnace

A high-temperature cracking and domestic waste technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of low efficiency, long cracking time, incomplete cracking reaction, etc., and achieve high cracking efficiency, complete cracking reaction, The effect of ensuring convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

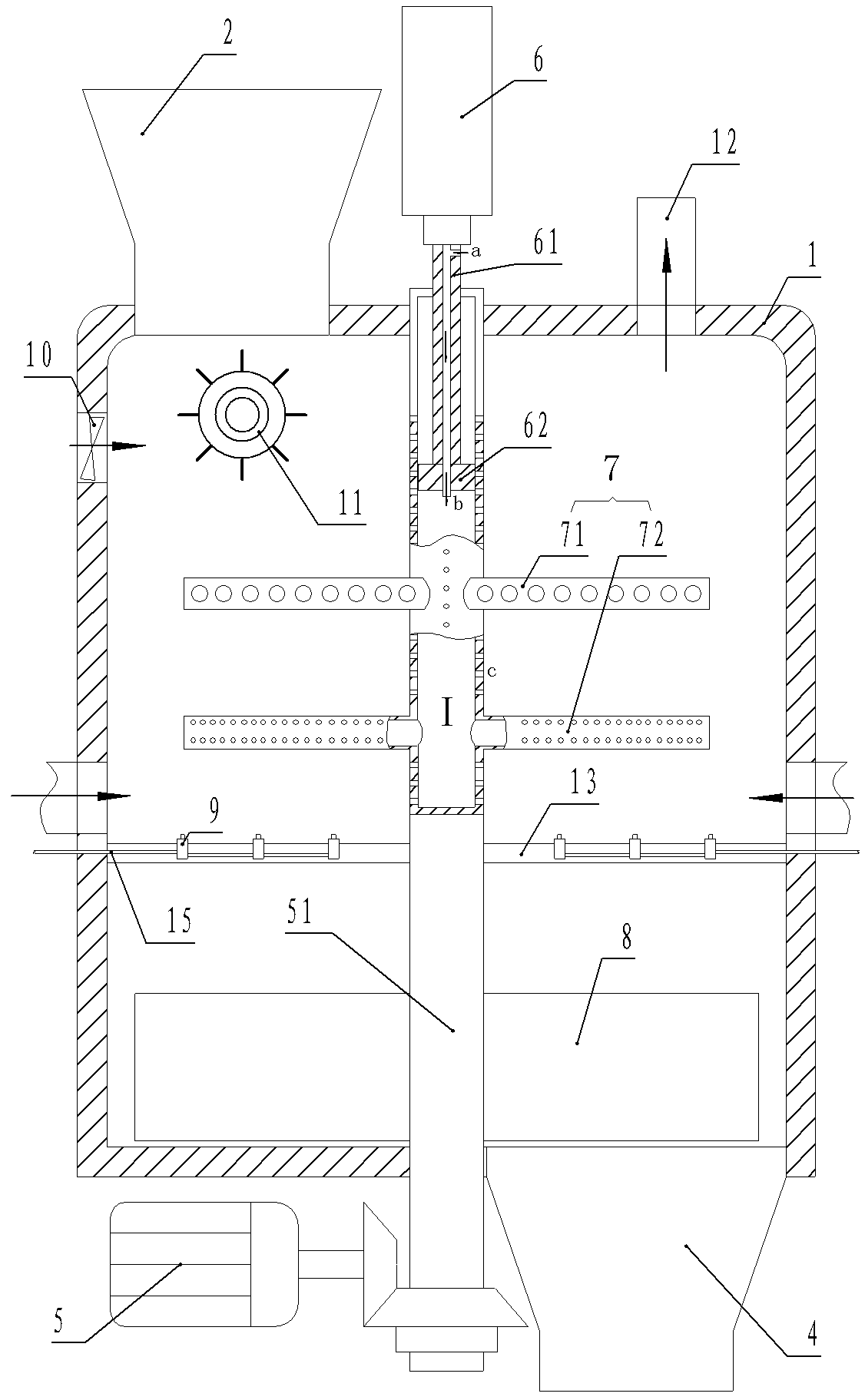

[0021] figure 1 The high-temperature pyrolysis reaction furnace for domestic waste shown includes a furnace body 1, a rotating shaft 51 is installed between the top plate and the bottom plate of the furnace body, and a rotating shaft motor 5 that drives the rotating shaft 51 to rotate is provided at the bottom of the furnace body 1; the furnace body The top of 1 is located above the rotating shaft 51, and a pressure cylinder 6 with its telescopic end protruding downward is provided; one side of the pressure cylinder 6 is provided with a feed hopper 2, and the other side is provided with a flue gas pipe 12 communicating with the flue gas outlet , the bottom end of the furnace body is provided with an ash hopper 4; the furnace body 1 is provided with a fire grate 13 between the feed hopper 2 and the ash hopper 4, and an additive chamber is provided in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap