Aluminium-plastic co-extrusion profile externally buckled aluminum plate structure

A technology of extruding profiles and aluminum gussets, applied in building components, building structures, windows/doors, etc., can solve problems such as poor hardness of foamed plastics, and achieve the effects of reducing carbon emissions, improving appearance, and improving social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

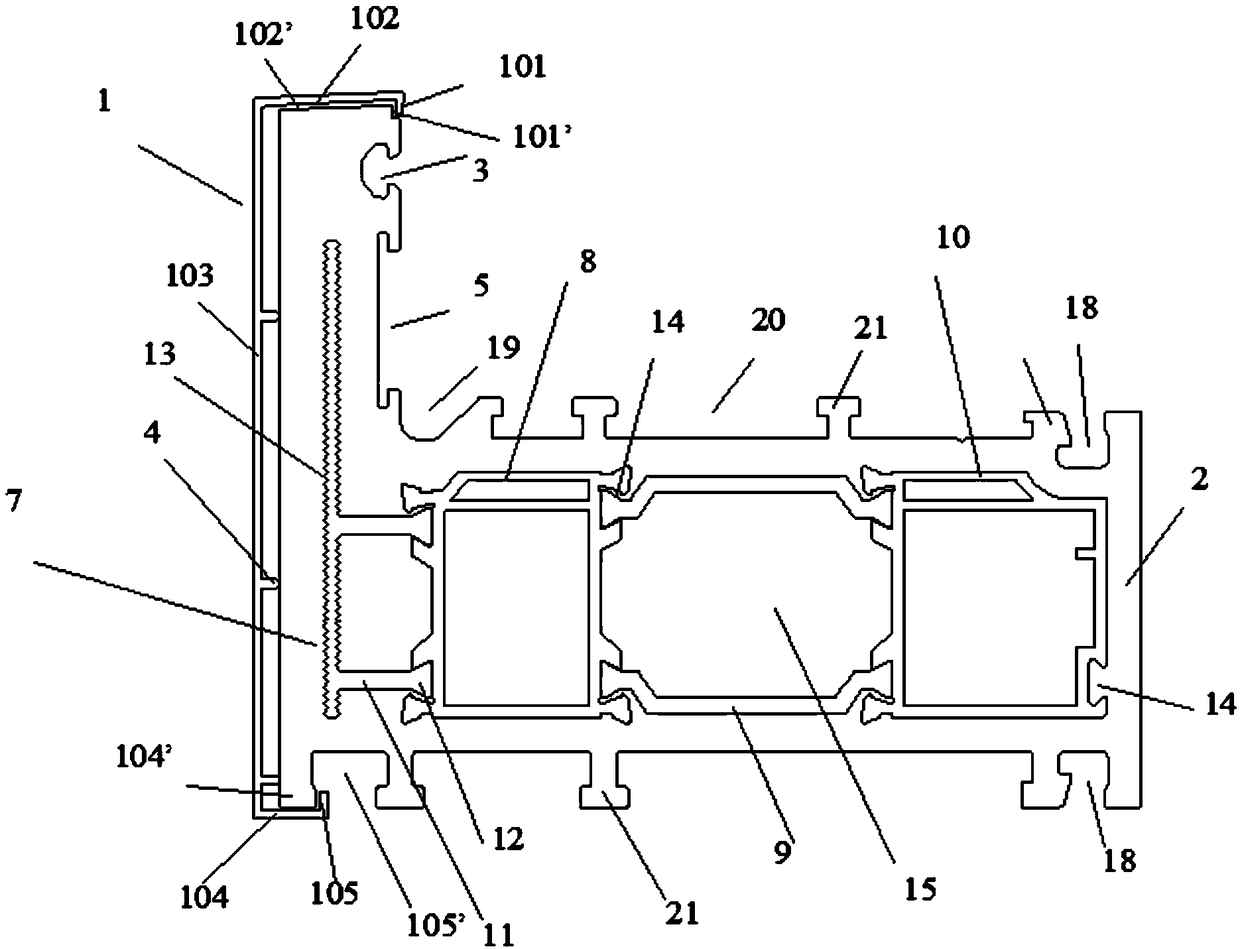

[0020] Such as figure 1 As shown, an aluminum-plastic co-extruded profile outer buckle aluminum plate structure of the present invention includes an aluminum-plastic co-extruded profile, and the outer side of the aluminum-plastic co-extruded profile is covered with an aluminum gusset 1, the aluminum gusset 1 is a semi-enclosed shape, and the aluminum The gusset plate 1 has a thickness of 0.8-1.2mm, and includes the first hook plate 101, the first inclined plate 102, the first vertical plate 103, the first horizontal plate 104 and the second hook plate 105 which are integrally connected, and the aluminum gusset plate 1 A plurality of support points 4 are provided on the inner side facing the aluminum-plastic co-extruded profile, and the aluminum buckle plate 1 is buckled on the outer side of the aluminum-plastic co-extruded

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap