Efficient grinding equipment for hot-melt reflective coating

A reflective coating and high-efficiency technology, applied in grain processing and other directions, can solve the problems of high cost and complicated operation steps, and achieve the effect of improving the efficiency and effect of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] As a preferred embodiment of the present invention, the filter hole diameter of the filter plate 12 is 5-8 mm.

[0022] As a preferred embodiment of the present invention, a shock-absorbing layer is provided on the bottom surface of the support leg 2, and the shock-absorbing layer is made of soft rubber material.

[0023] As a preferred embodiment of the present invention, the surface of the rolling roller 5 is provided with stripes.

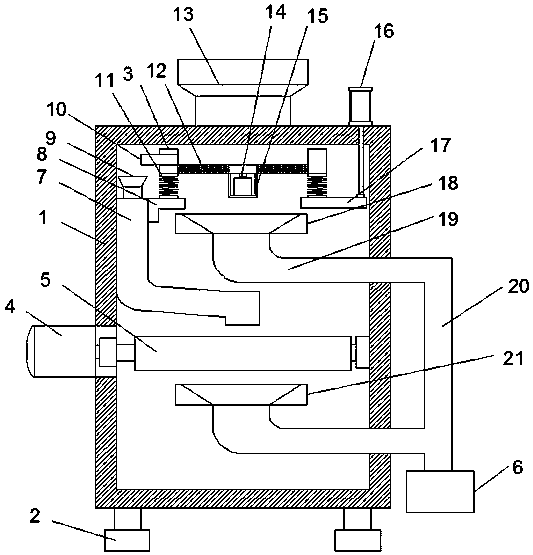

[0024] In this high-efficiency grinding equipment, by setting a fruit filter screen inside the equipment shell, the vibration of the vibrator to the filter screen can realize the separation of large-grained raw materials. The coating powder that meets the conditions is collected and sent to the outside through the first collection hopper, and then separated The large particles are crushed and crushed by the rolling roller. With this design, the rolling roller only needs to crush the large particles, which improves the rolling efficiency and

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap