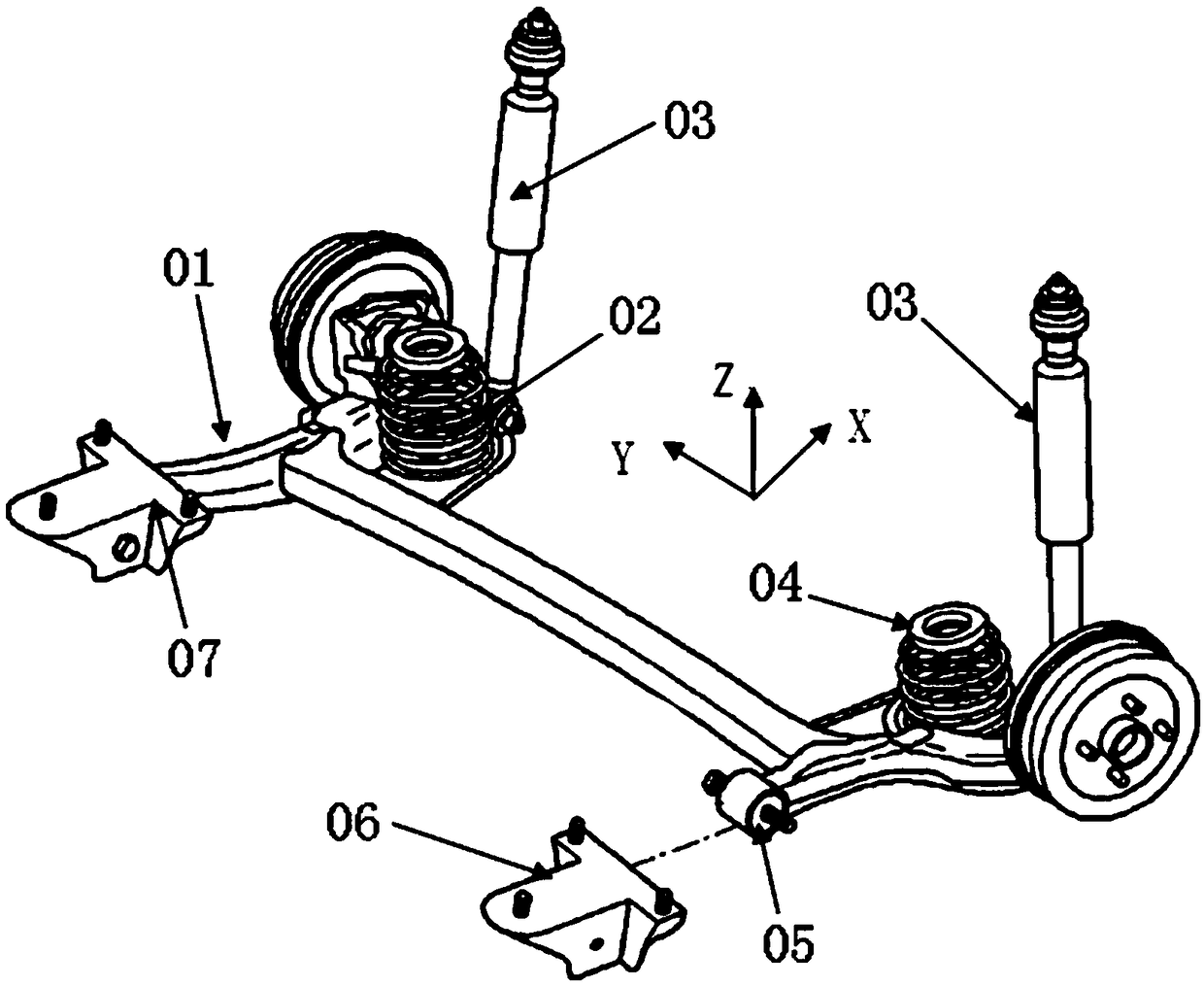

Composite spring, torsion beam and axle suspension assembly

A composite material and suspension assembly technology, applied in the field of suspension systems, can solve problems affecting vehicle stability, vehicle oversteer, etc., and achieve the effects of reducing weight, reducing frictional noise of connections, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

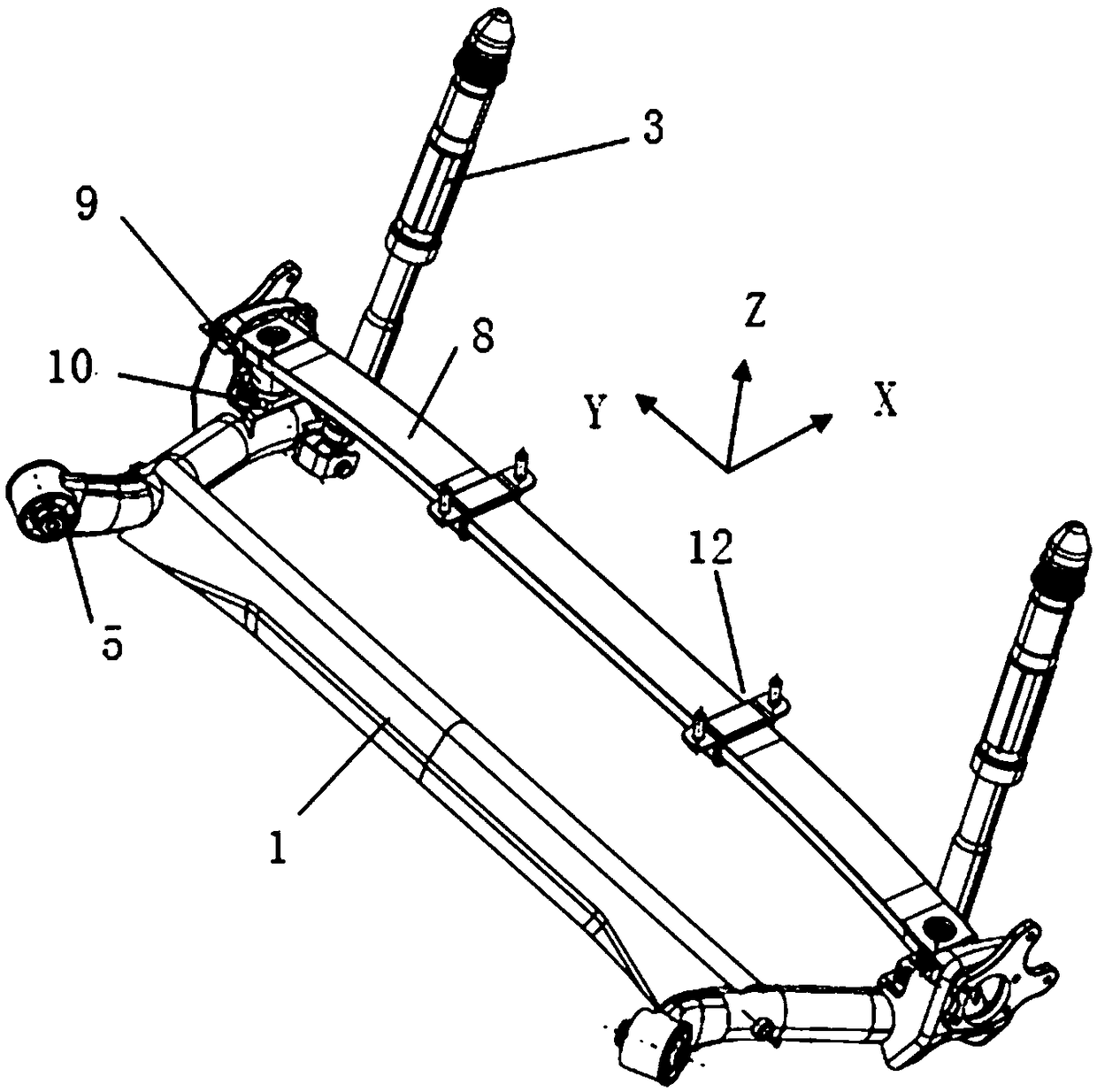

Embodiment Construction

[0059] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

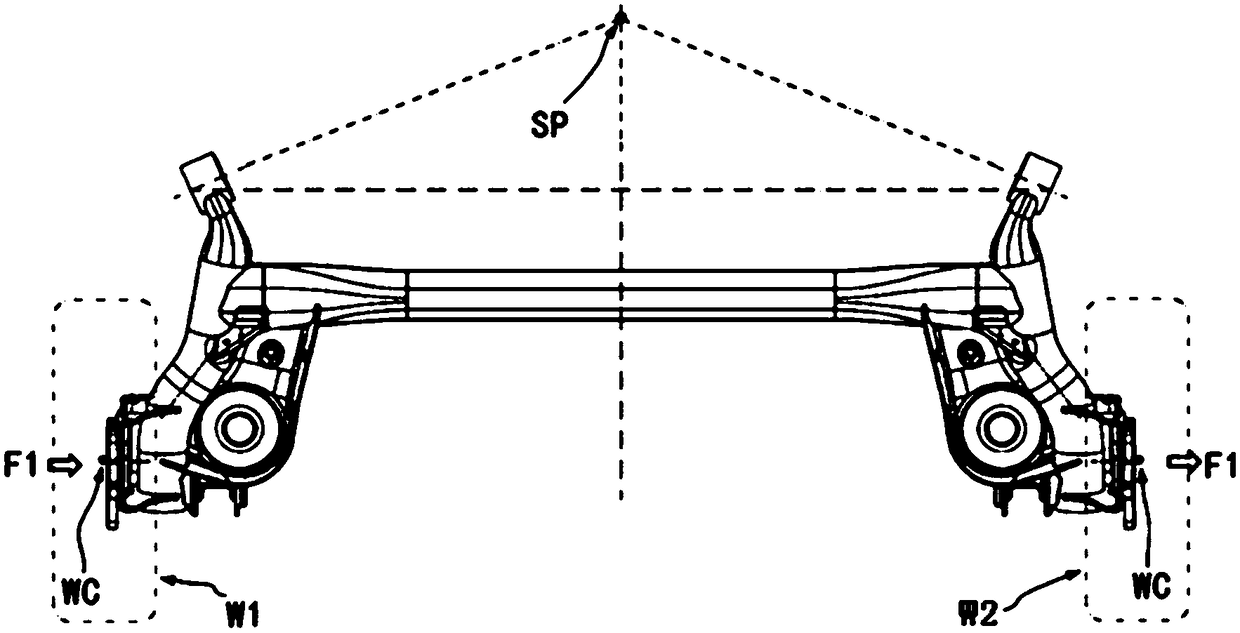

[0060] In this application, a horizontal composite material spring is used to replace the coil spring. The middle part of the horizontal composite material spring is fixed on the vehicle body, and the two ends of the composite material spring are connected to the coupling torsion beam through cylindrical rubber pads. Because the cylindrical rubber pad restricts the movement of CTBA in the Y direction , when the vehicle is turning, the limitation of the rotation around the Z axis is changed from the original two flexible restrictions of the two front bushes to the four flexible restrictions composed of the front two bushes and the rear two c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap