Partial quick-change combination punch for punching when internal high-pressure forming

An internal high pressure, punch technology, applied in the field of machinery, can solve the problem of wasting materials and labor, and achieve the effect of reducing consumption, rapid replacement, and reducing the workload of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

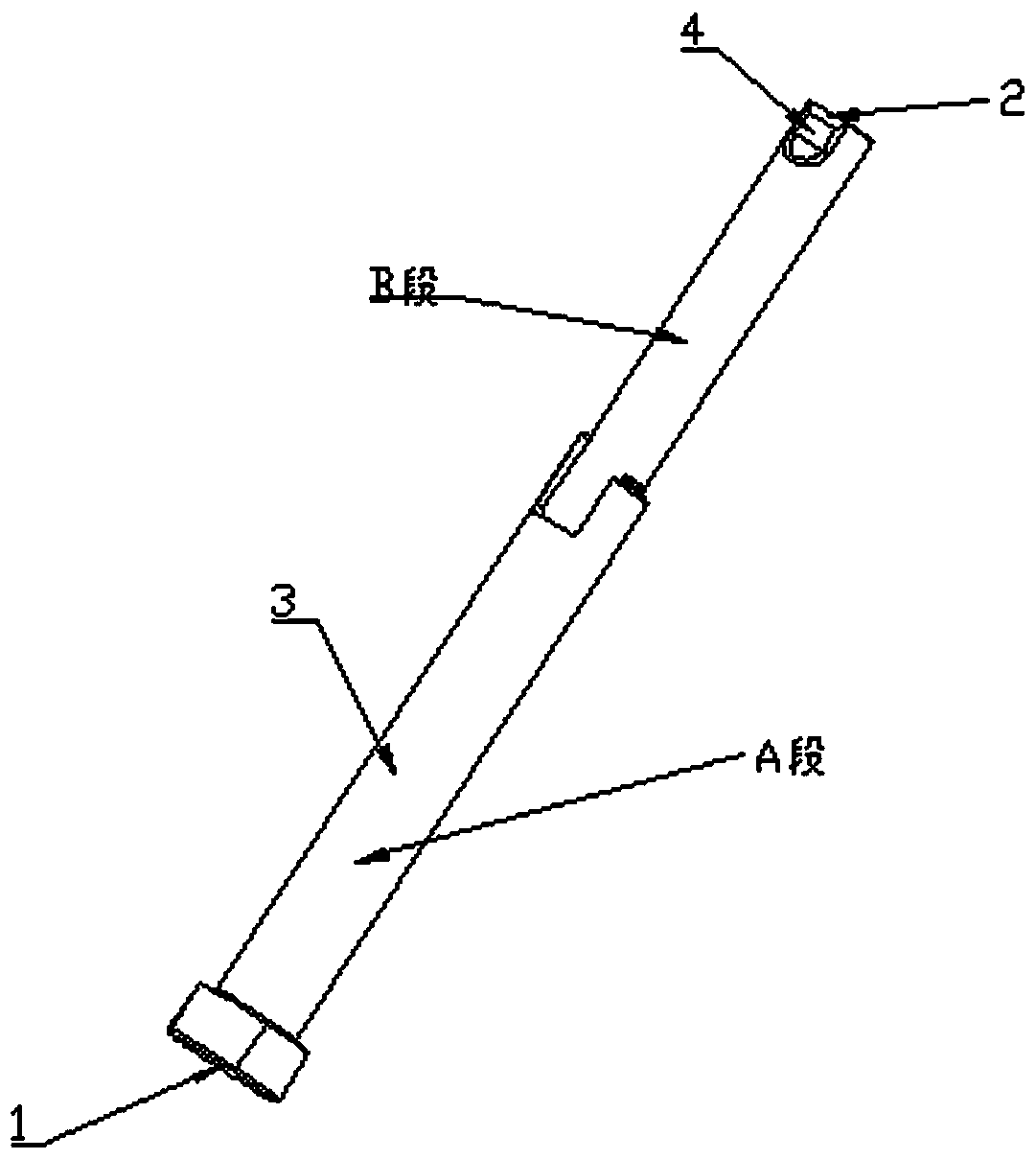

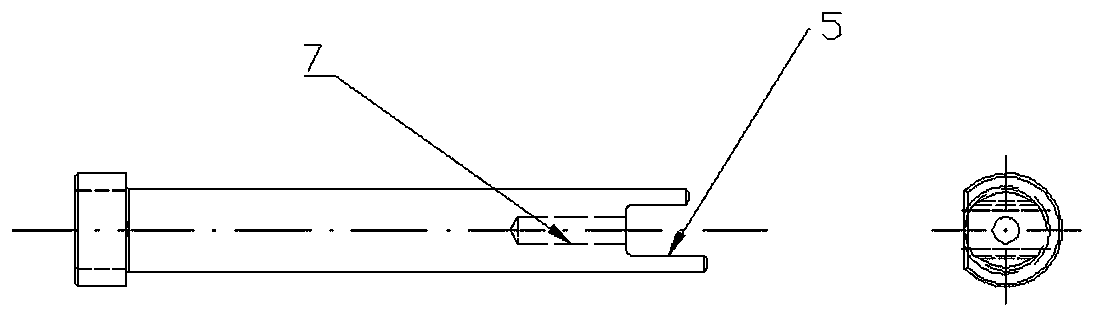

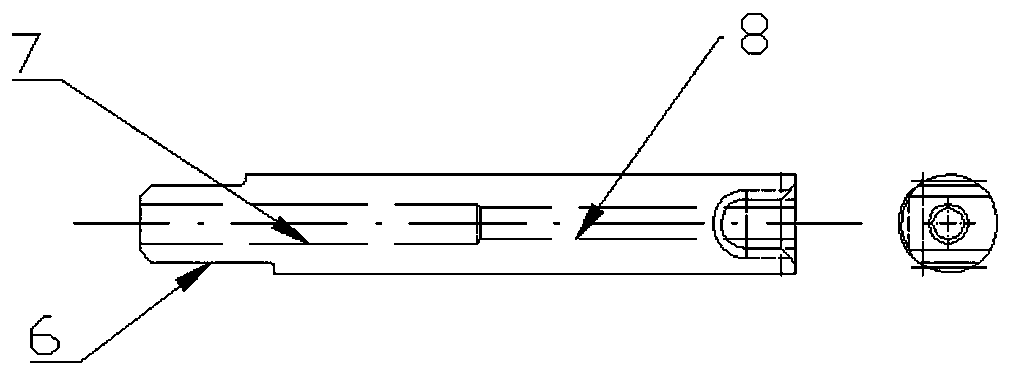

[0014] Refer to figure 1 , The punch of the present invention includes a base 1, which is matched with the punch fixing fixture, a cutting edge 2, punched on the inner high-pressure forming part 2, a cylindrical straight rod part 3 between the base and the cutting edge, wherein the base 1 is A column with a chord-cut circle in cross section. The diameter of the arc part of the cross section of the base 1 is larger than the diameter of the straight rod part 3. The length of the straight rod part is determined by the wall thickness of the mold at the punching point of the molded part. The mouth line is in the shape of a chord tangent circle. The side cut surface 4 on the straight rod at the edge of the punch and the end face of the straight rod intersect to form a chord tangent round edge 2. The axial length of the side cut surface 4 on the straight rod is given by the punch. When it reaches the dead point, the end is still outside the molded part; the improvement is: the punch is di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap