Counter flow type hot air combustion furnace

A combustion furnace and counter-flow technology, applied in the field of combustion furnaces, can solve the problems of waste gas emission polluting the environment, real-time adjustment of feed amount, insufficient combustion, etc., and achieve the effect of ensuring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

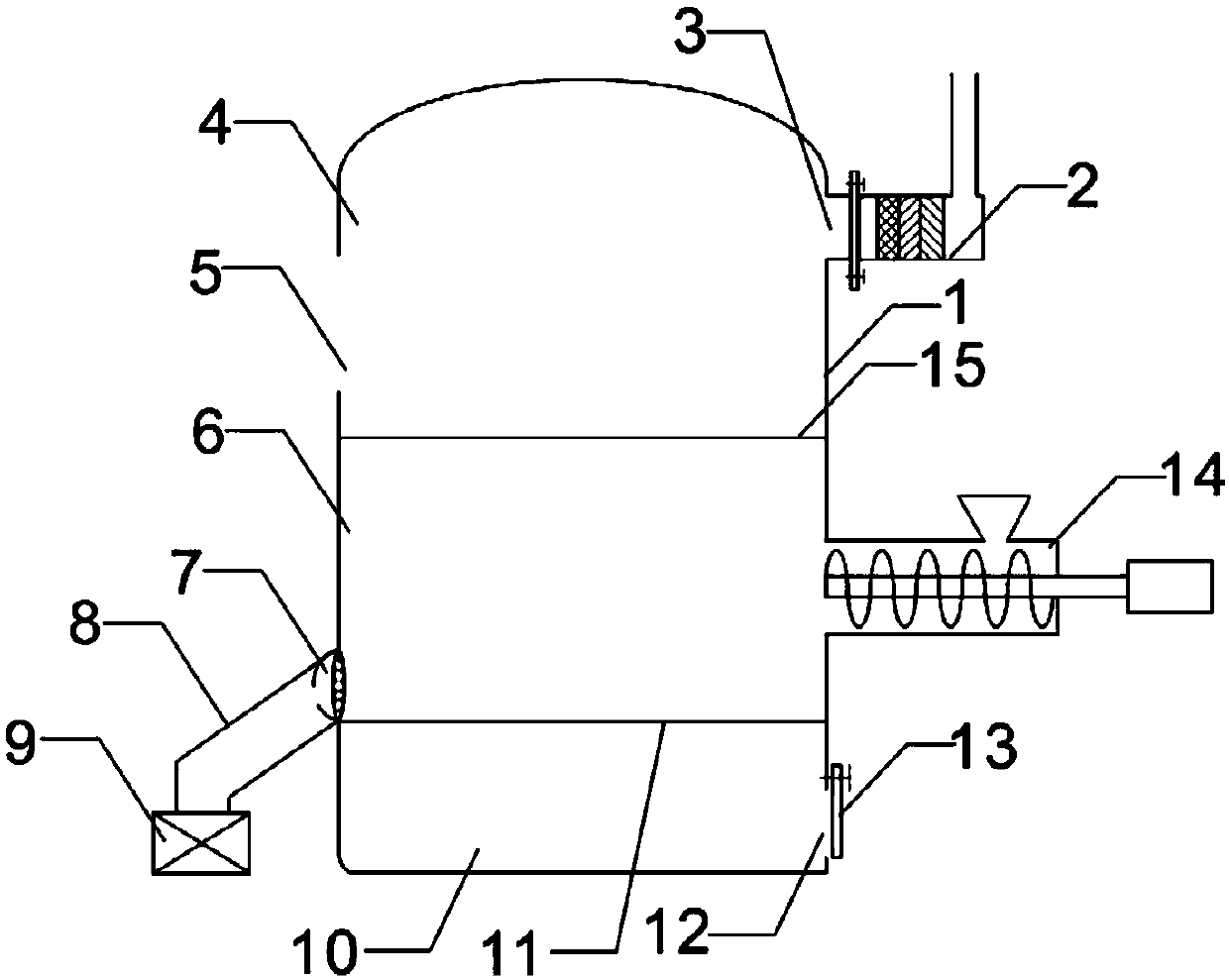

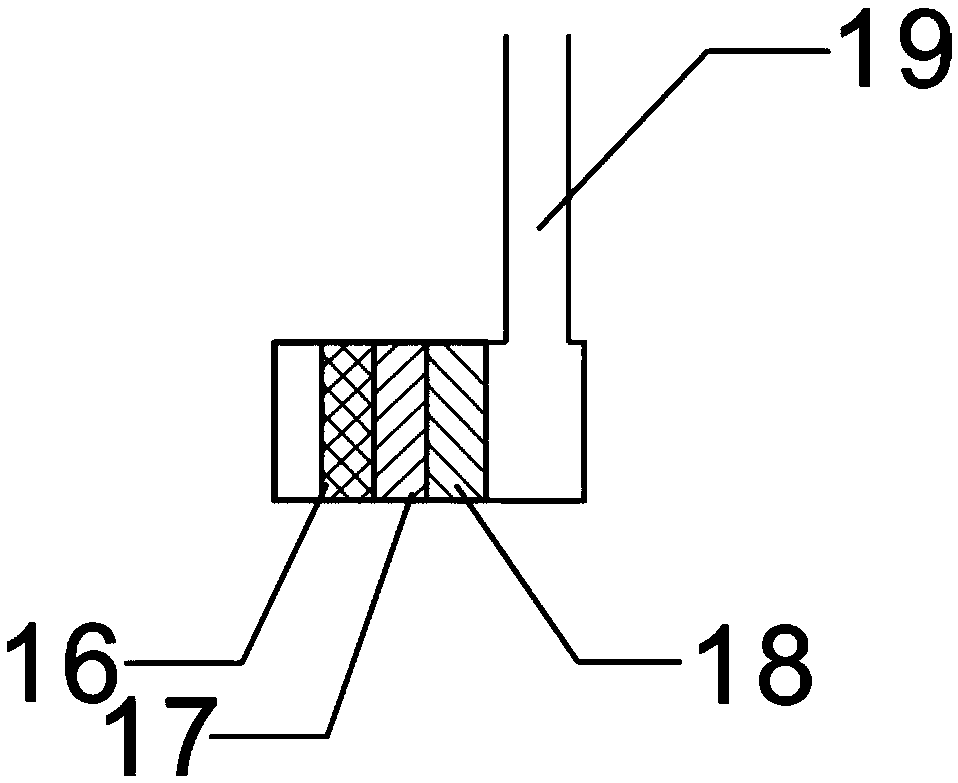

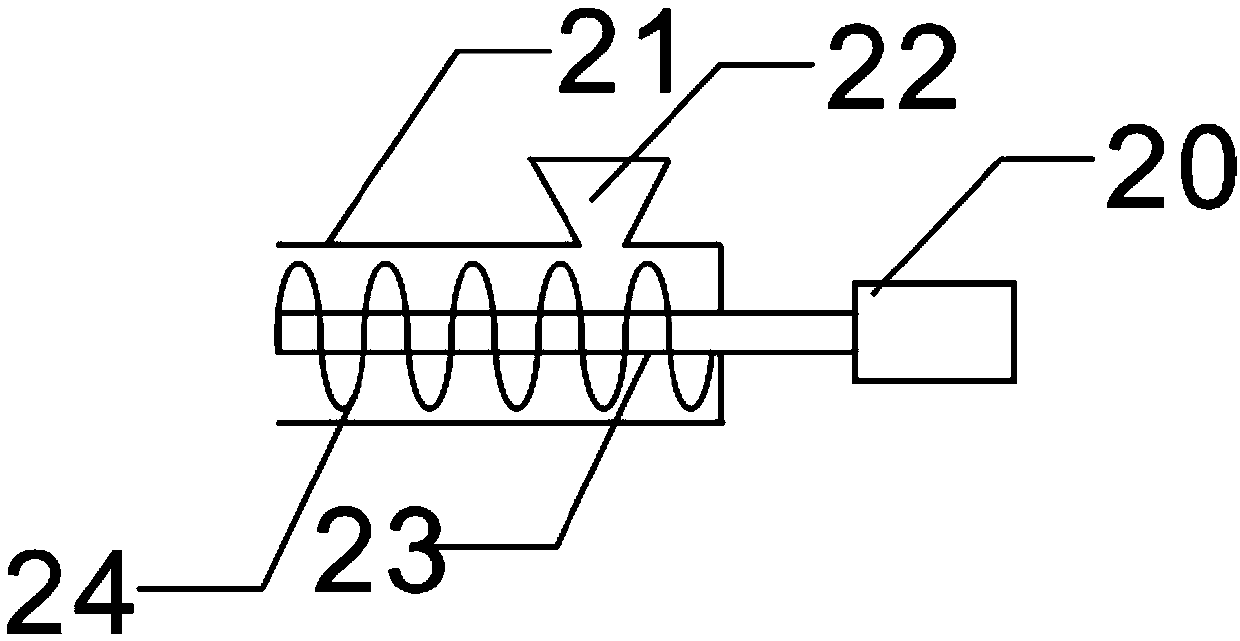

[0022] In an embodiment of the present invention, such as Figure 1-4 As shown, a counter-flow hot-blast combustion furnace is provided, which includes a furnace body 1. A flame stabilizing plate 15 and a burning plate 11 are arranged in the furnace body 1. The flame stabilizing plate 15 and the burning plate 11 sequentially connect the furnace body 1 from top to bottom. It is divided into flame zone 4, combustion zone 6 and slag zone 10. The flame stabilizing plate 15 set above the combustion zone 6 can stabilize the flame and block the dust after combustion to make the flame evenly distributed; the flame zone 4 is set on the left side There is a fire outlet 5, the right side of the flame zone 4 is provided with an air outlet 3, and the air outlet 3 is connected with an air outlet device 2 that can absorb smoke through a flange. Flame or steam is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap