Cable laying device

A technology for laying devices and cables, applied in the direction of cable laying equipment, etc., can solve the problems of rapid cable damage and achieve the effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

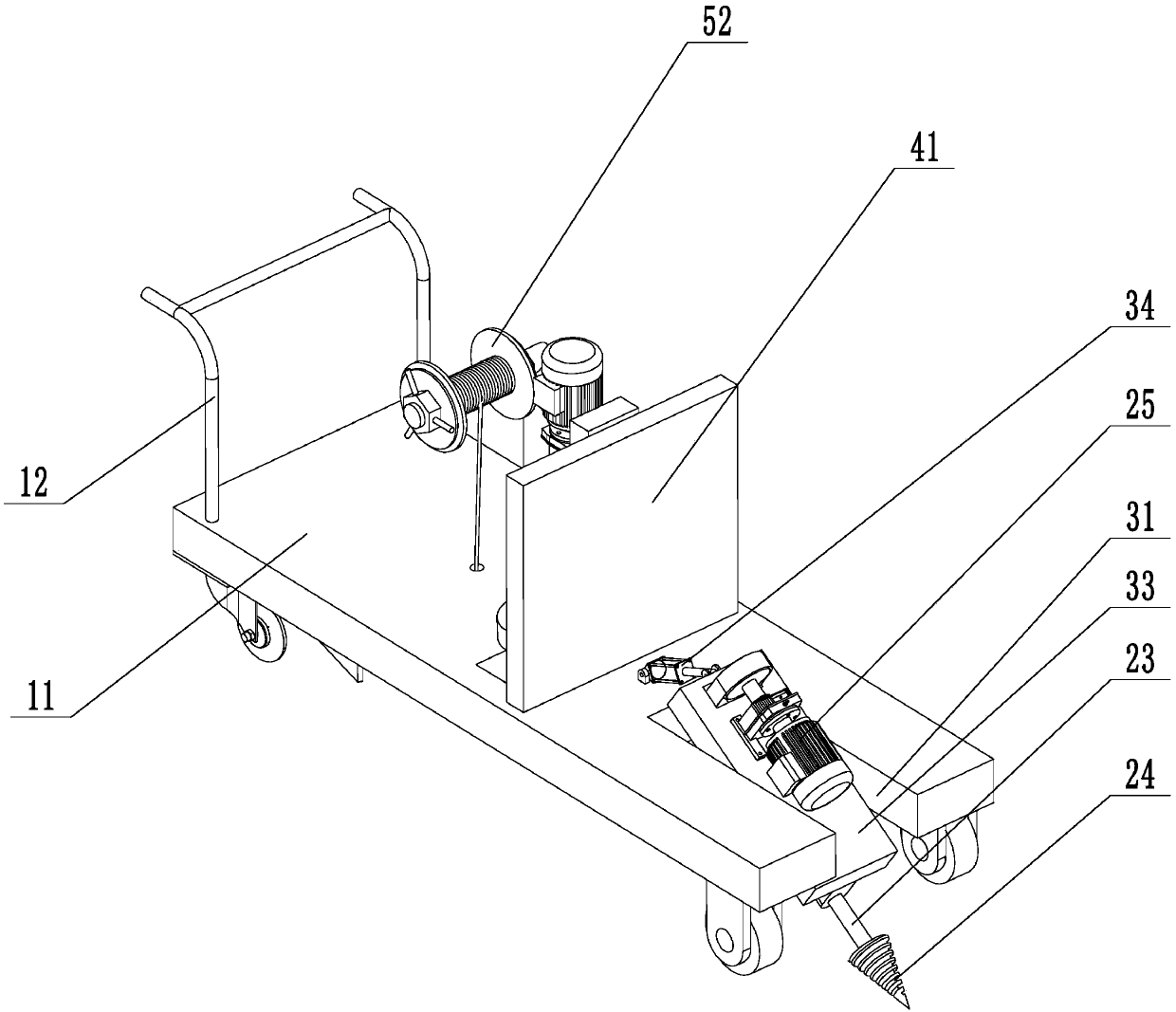

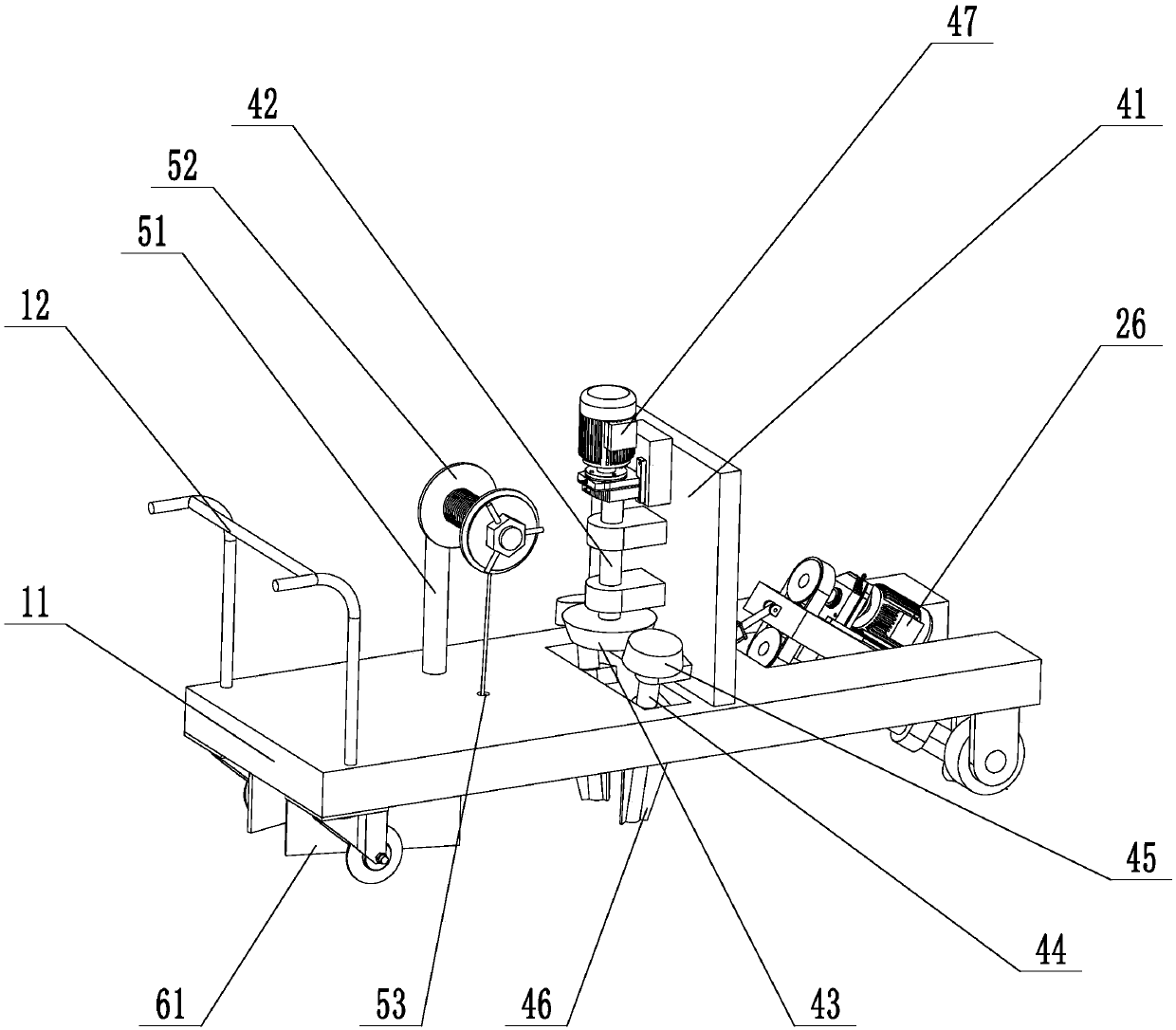

[0049] refer to figure 1 , is a cable laying device disclosed in the present invention, including a slotting mechanism, an expansion mechanism, a laying mechanism and a back-embedding mechanism. These four parts are all installed on the mobile base 11. Platform and four walking wheels installed on the bottom surface of the workbench, one side of the mobile base 11 is welded with handrails 12, which is convenient for the staff to promote.

[0050] For the convenience of description, the side on which the handrail 12 is welded on the mobile base 11 is called the rear side, and the side opposite to this side is called the front side.

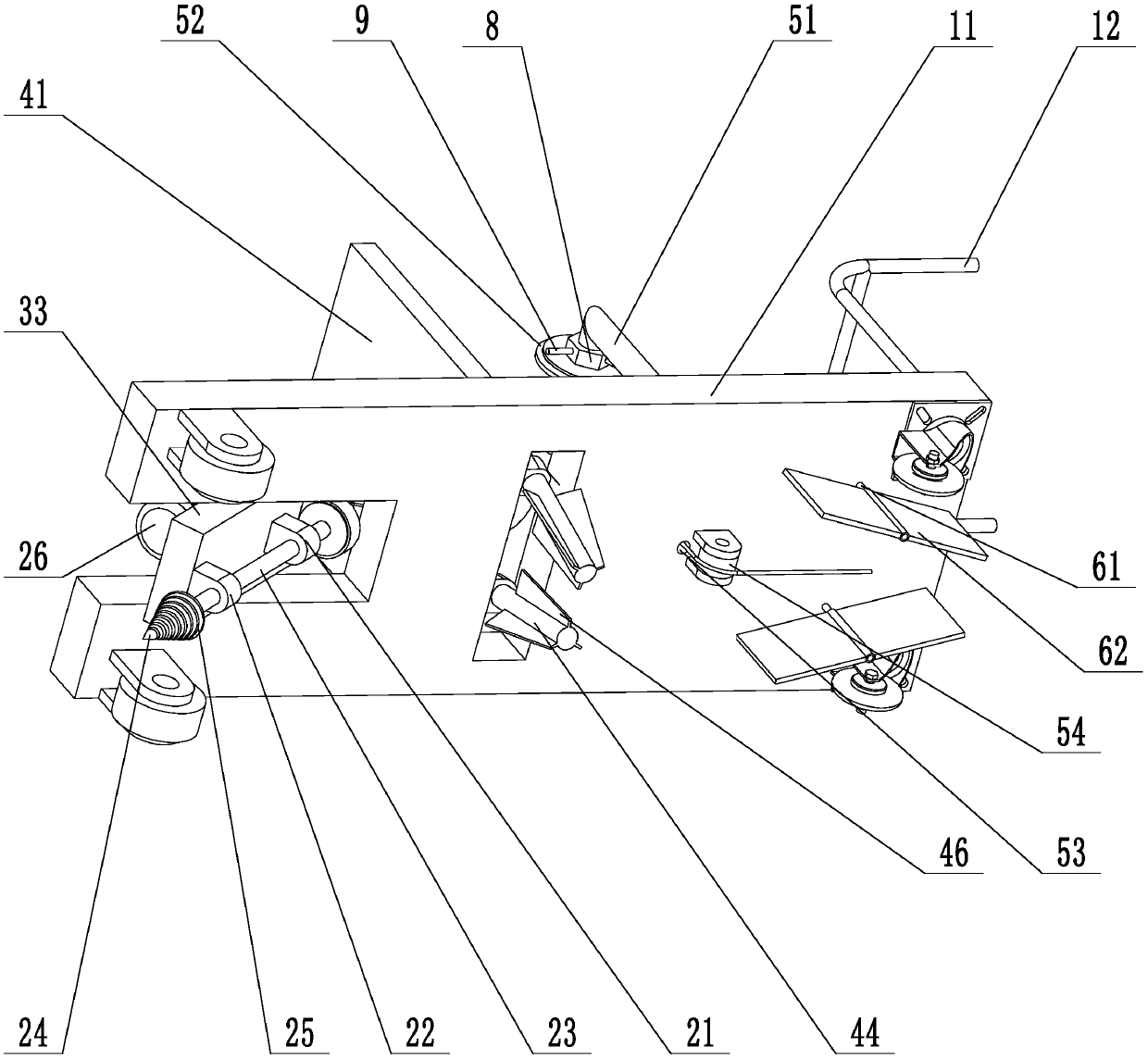

[0051] refer to figure 2 and image 3 , the long hole 31 is opened at the place near the front side of the mobile base 11 , and the rotating plate 33 is sleeved on the rotating shaft 32 and can rotate around the rotating shaft 32

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap