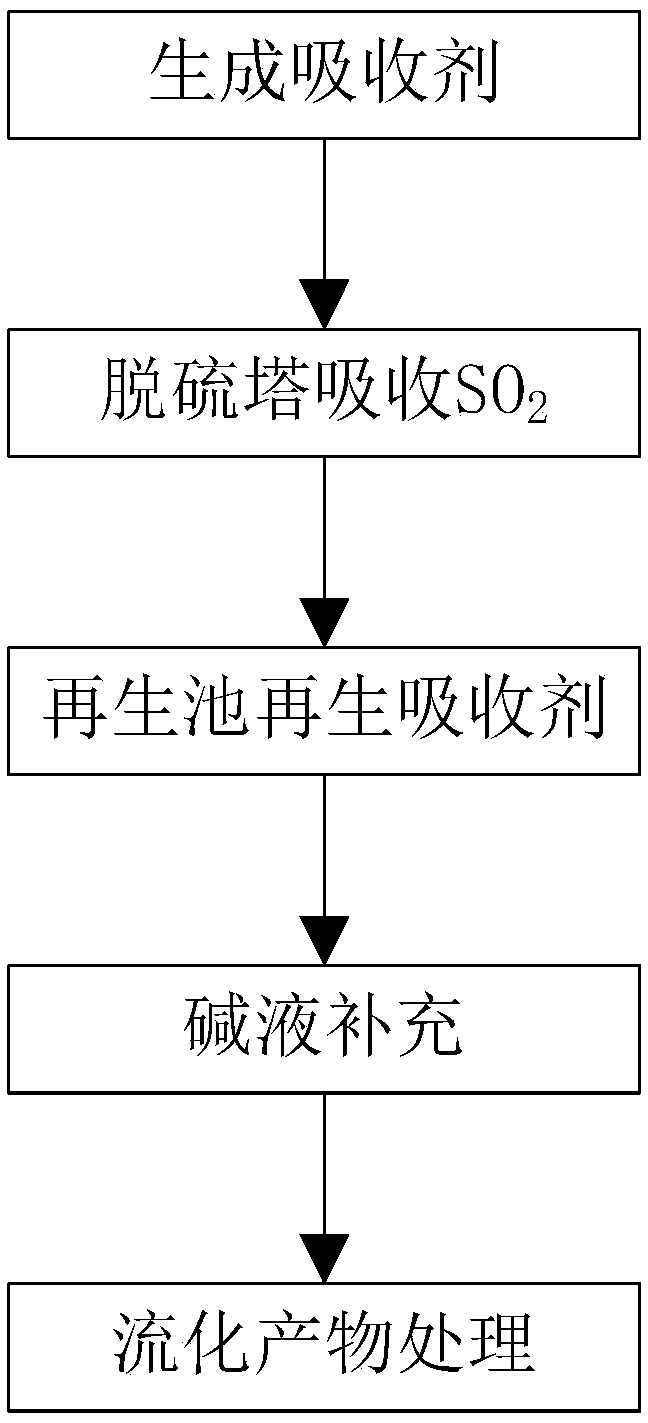

Double-alkali flue gas desulfurizing method

A dual-alkali method and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of destroying ecological balance, acid rain, building corrosion and damage, etc., to reduce volume and save desulfurization cost, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

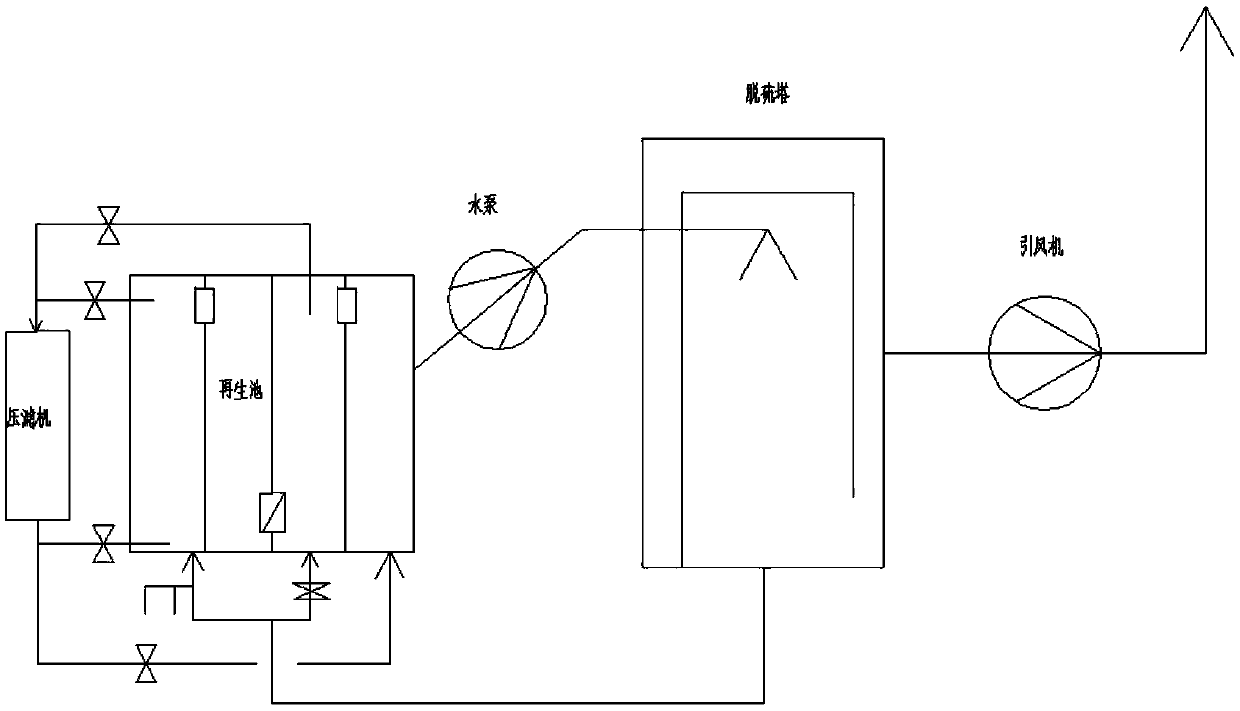

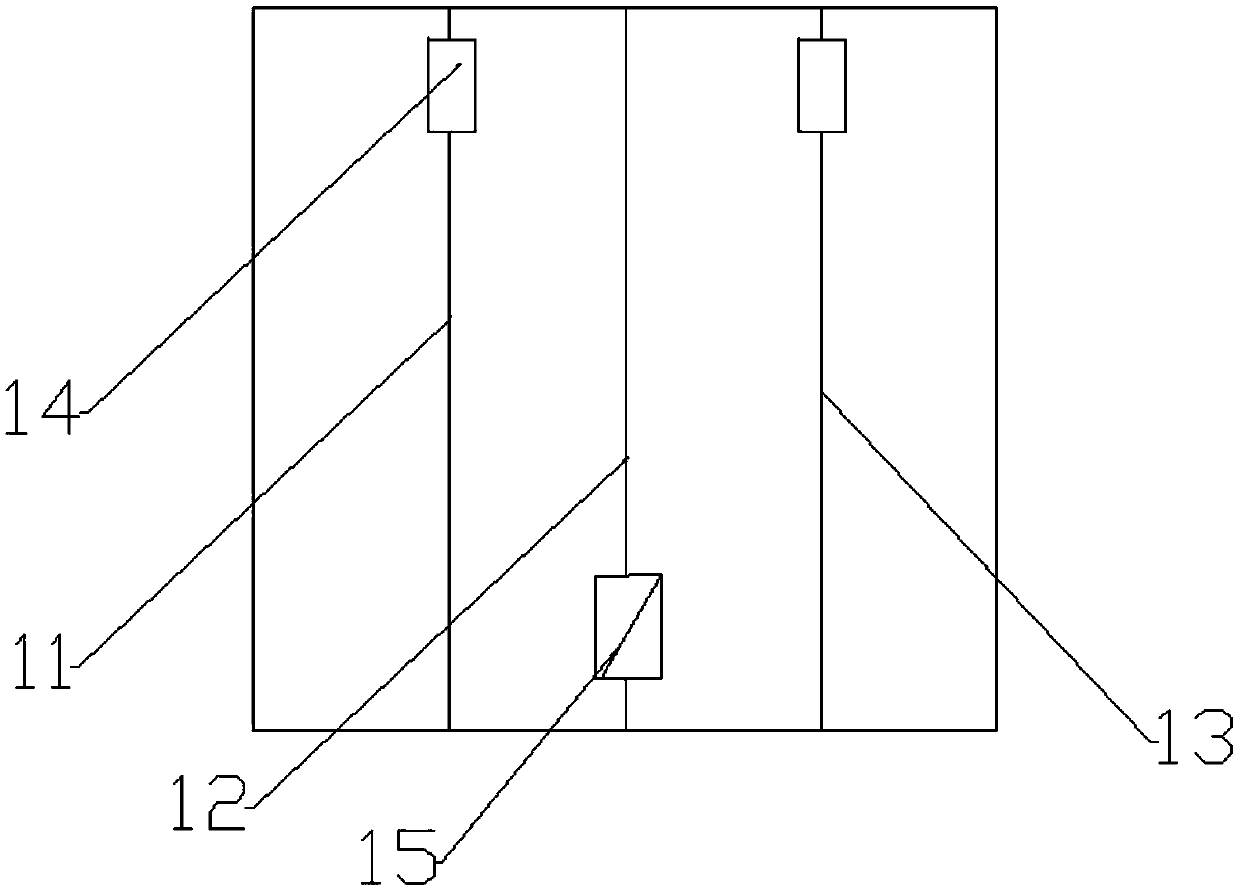

[0021] A double-alkali flue gas desulfurization equipment, such as Figure 2-3 As shown, it includes a desulfurization tower, a regeneration tank and a filter press. The regeneration tank is divided into four treatment tanks in sequence by three partitions. From left to right, they are the first treatment pool, the second treatment pool, and the third treatment pool. And the 4th treatment pool, filter screen 14 is set on the first partition 11 and the 3rd partition 13; Preferably, filter screen 14 is arranged on the top of the first partition 11 and the 3rd plate 13, to guarantee that filter screen do

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap