Steel girder sling arch bridge construction method applicable to large environmental restriction

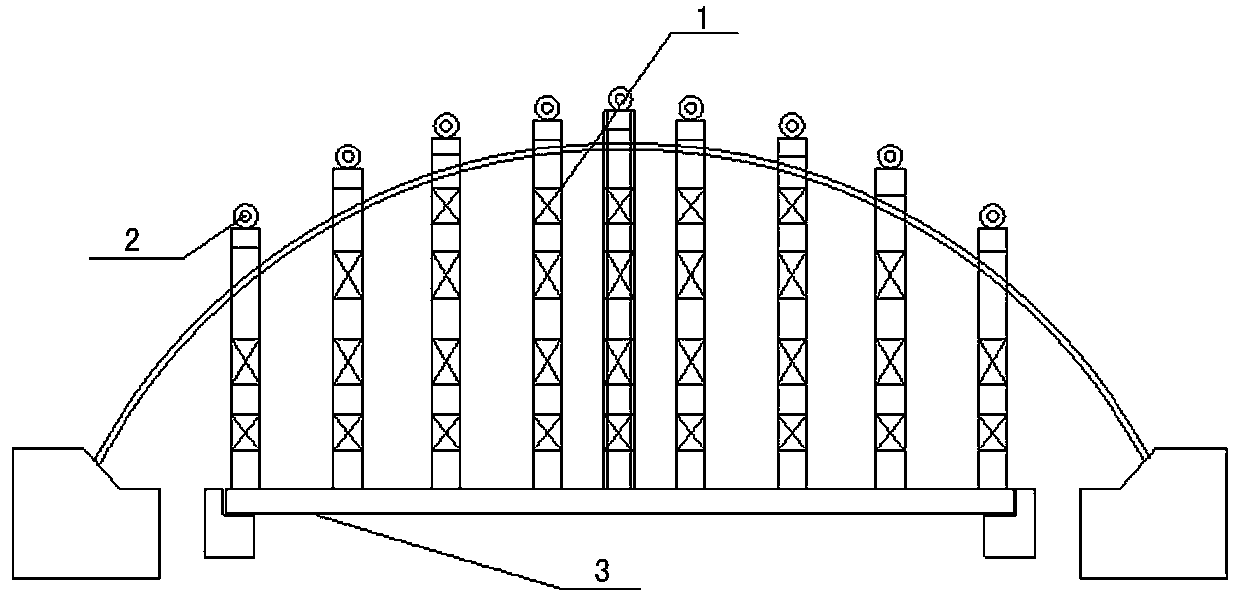

A construction method and technology for suspension arch bridges, applied to arch bridges, bridges, bridge forms, etc., can solve problems such as narrow construction sites, high traffic pressure on the ground, and many construction interference factors, so as to ensure construction quality, improve work efficiency, reduce The effect of the impact on residents and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

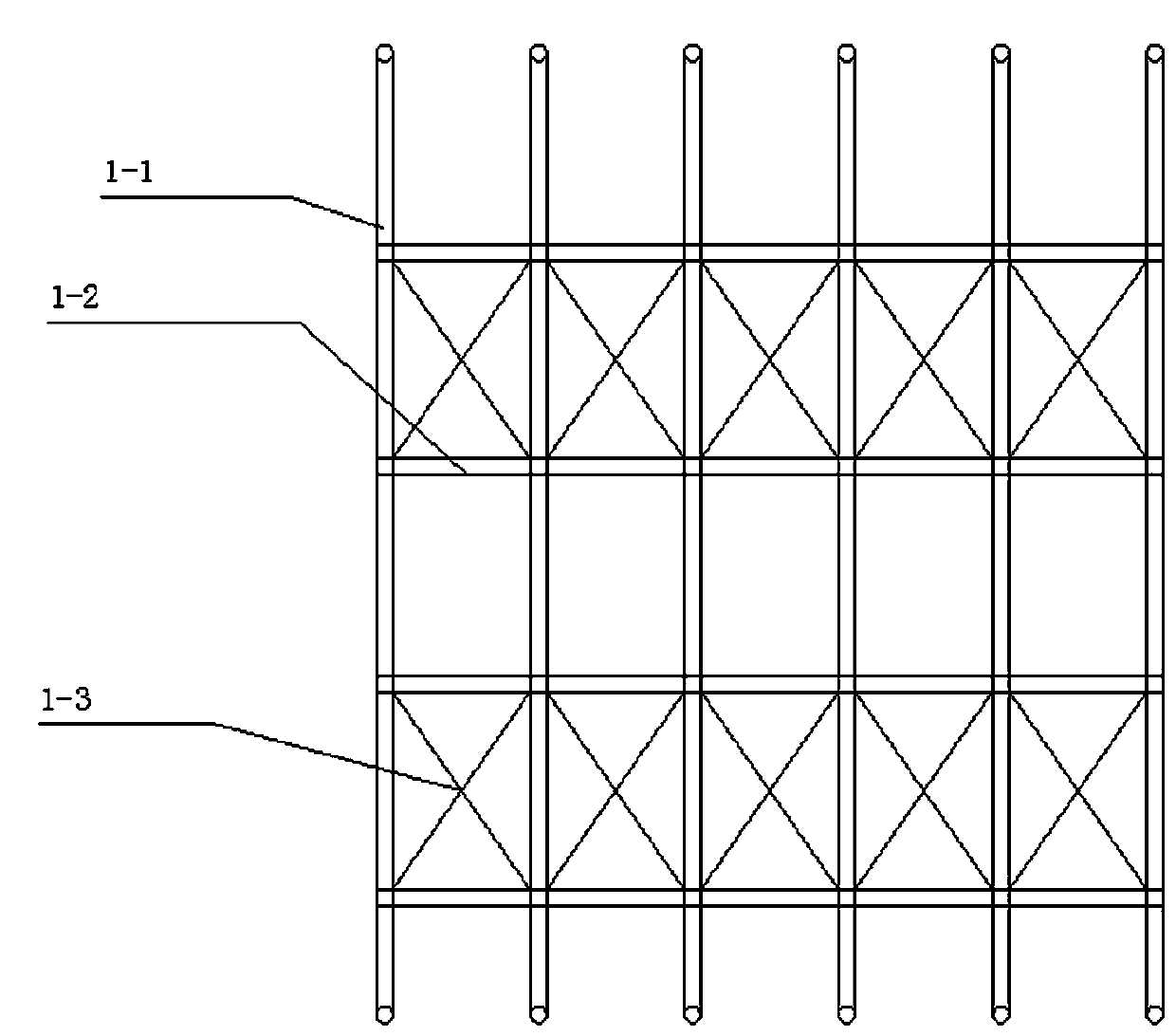

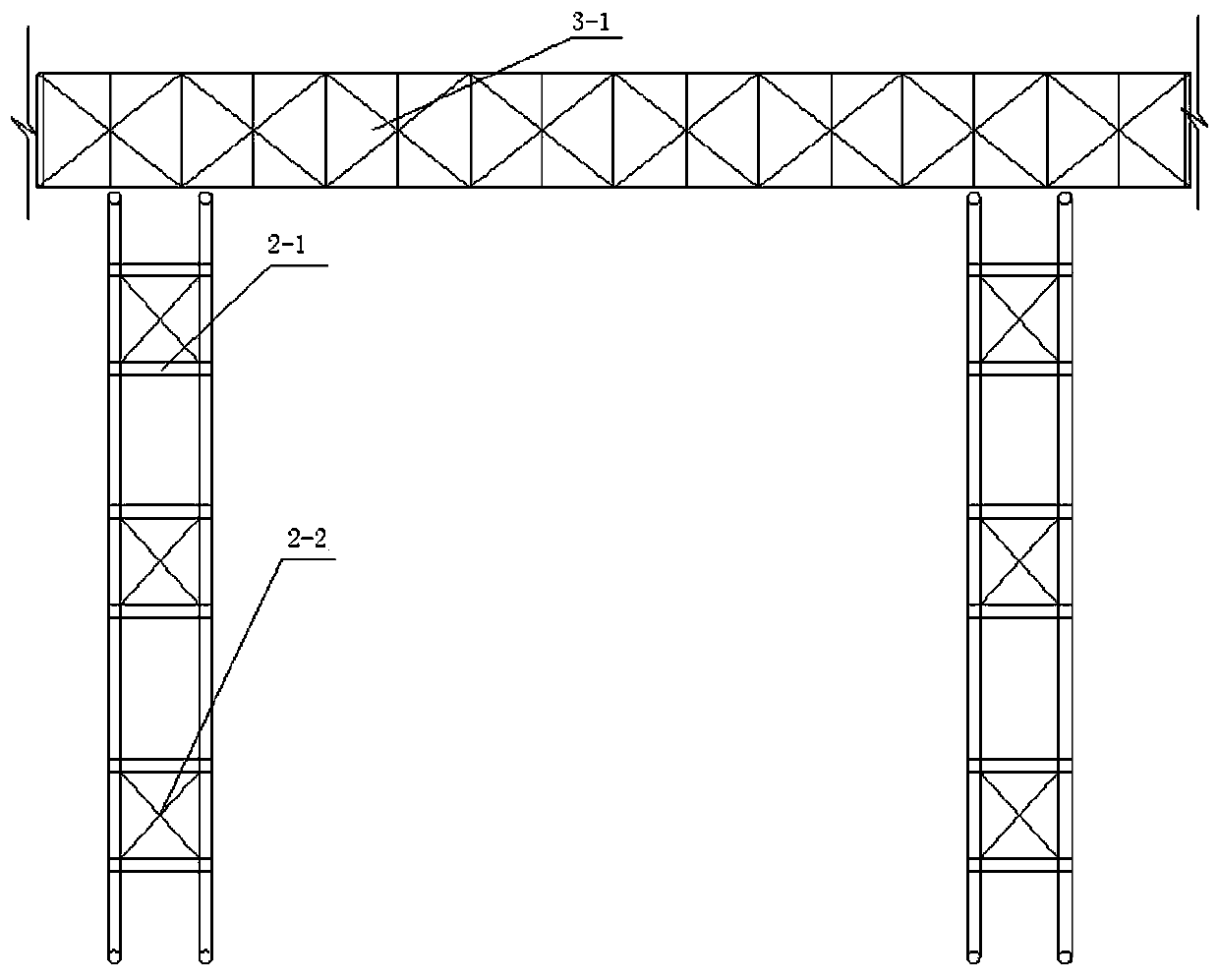

[0025] The overall construction process of steel truss girder assembly is: steel pipe pile insertion → horizontal and vertical scissor bracing welding → Bailey beam erection → distribution beam and panel layout → supporting pad jack setting → truck-mounted crane component delivery → lower chord → beam → lower leveling Link → web bar (oblique, vertical) → upper chord, upper flat link → longitudinal beam → horizontal link.

[0026] 1) Platform setup

[0027] The foundation of the temporary pier adopts the inserted steel pipe pile foundation, and the inserted depth is calculated and determined according to the geological conditions of the pier. Scissor braces are set between the steel pipe columns, so that each row of steel pipe columns is connected into an integral lattice column to enhance its stability.

[0028] Steel truss girder assembled platform structure such as figure 1 with 2 As shown, the platform is built with column beams, and the columns are based on inserted steel p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap