Flue gas desulfurization tower with characteristics of easy material discharging and easy impurity removing

A desulfurization tower, flue gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of secondary pollution, high operating energy consumption, difficult to meet standards, etc., to increase the reaction speed and avoid environmental pollution. , The effect of improving the removal rate of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

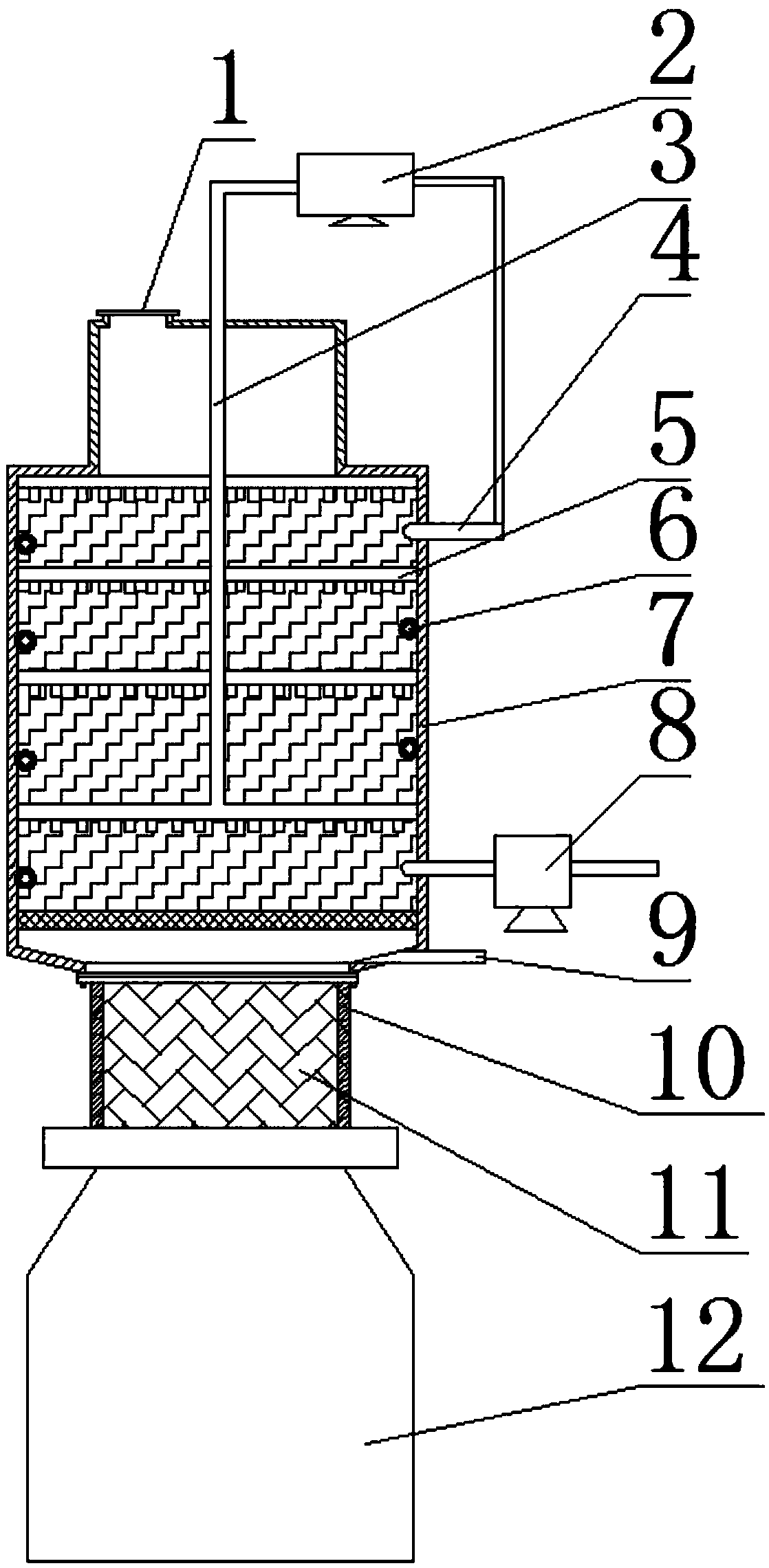

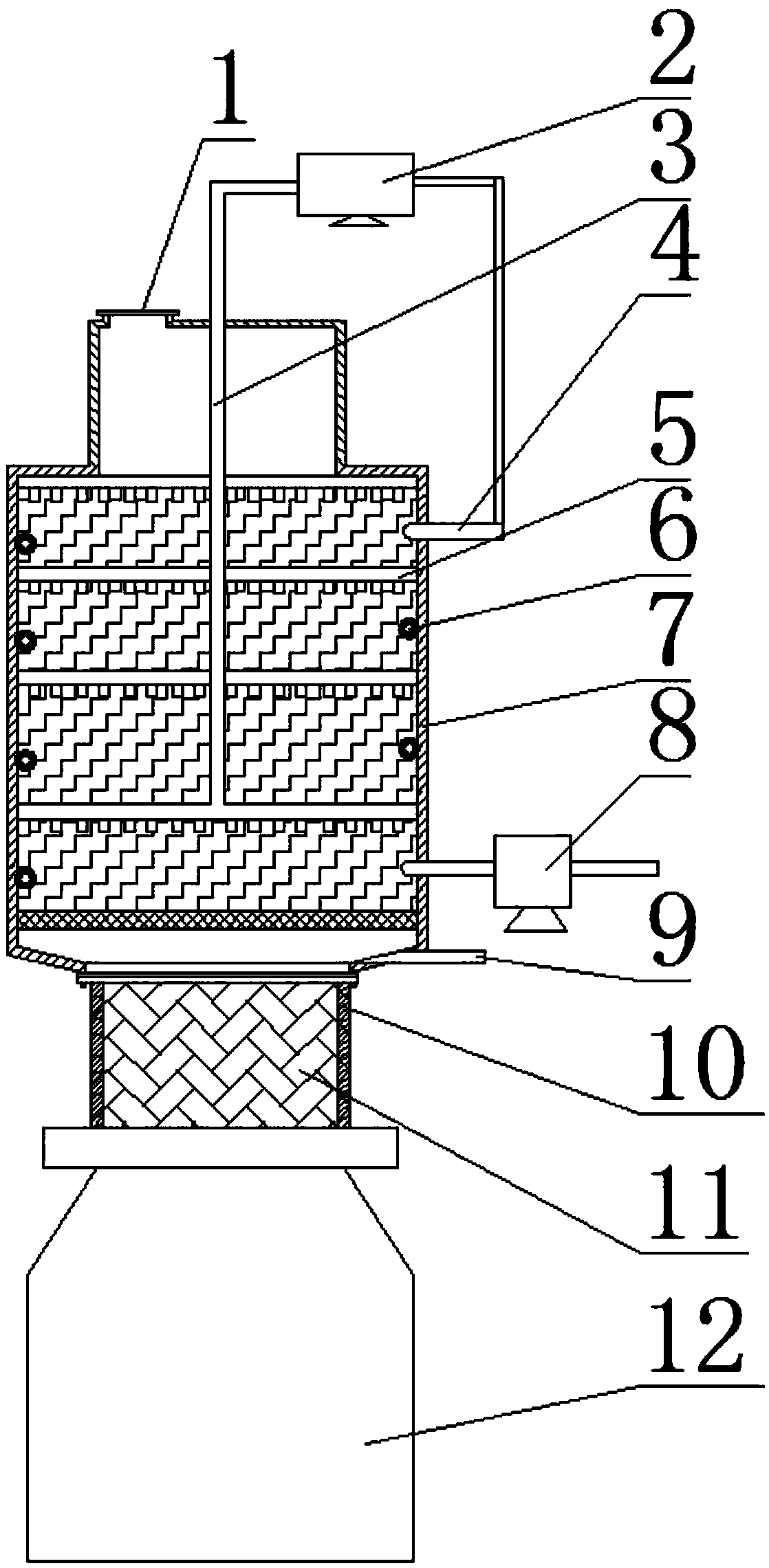

[0014] A flue gas desulfurization tower that is easy to discharge and remove impurities, including a desulfurization tower 7, a circulation system for impurity removal liquid, and a liquid collection tank 12. The upper part of the desulfurization tower is formed with an air outlet 1, and the lower side wall is formed with an air inlet 9. , the lower bottom of the desulfurization tower is coaxially equipped with a liquid outlet 10, the lower part of the liquid outlet is coaxially installed with an adsorption sleeve 11, the adsorption sleeve is filled with adsorption materials, the lower part of the adsorption sleeve is connected with a liquid collection tank, and the cleaning liquid flows down from the des

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap