Exhaust manifold

An exhaust manifold, exclusive technology, applied in the field of casting materials, can solve the problem of not achieving the maximum temperature difference, and achieve the effect of avoiding thermal bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

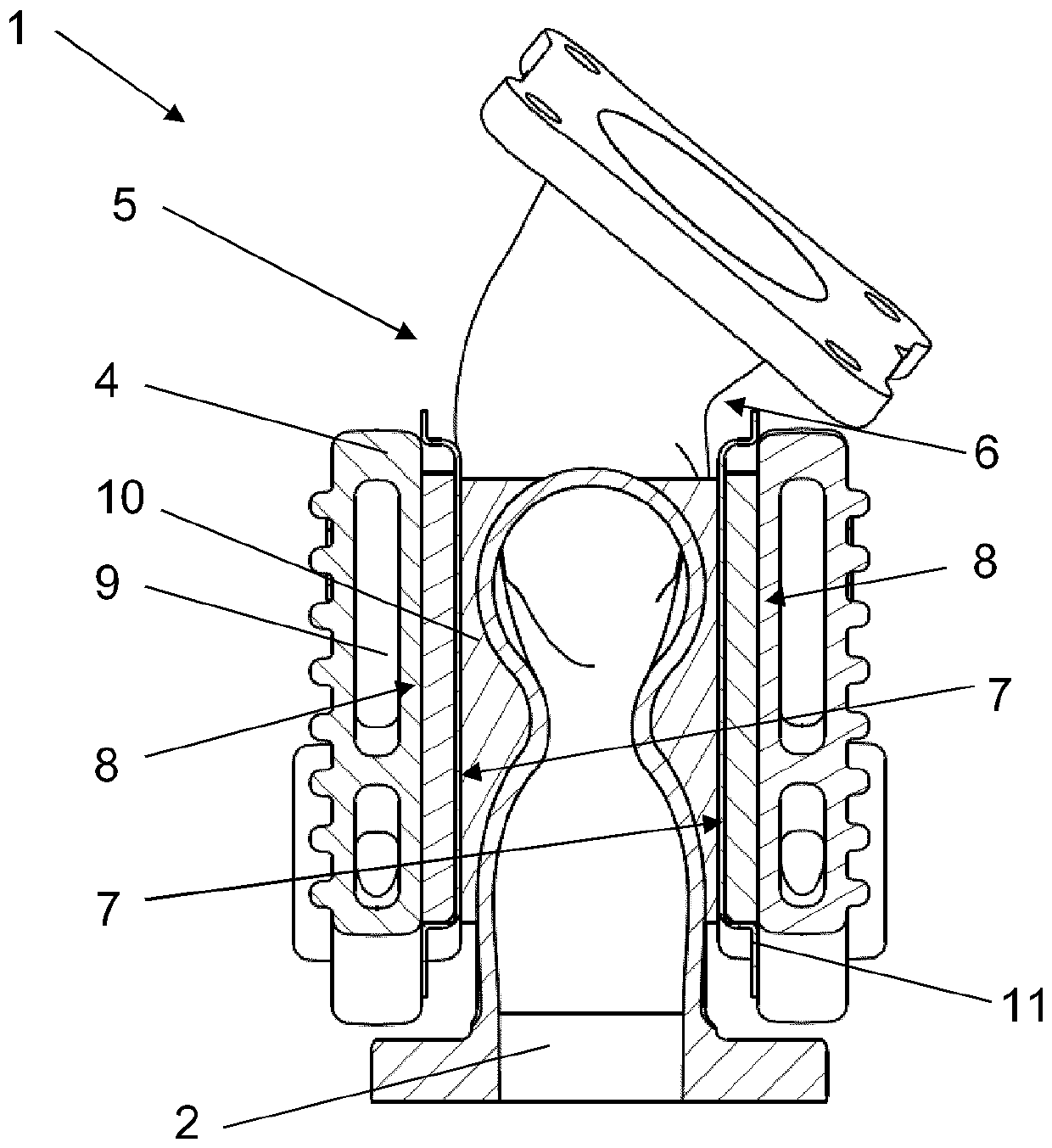

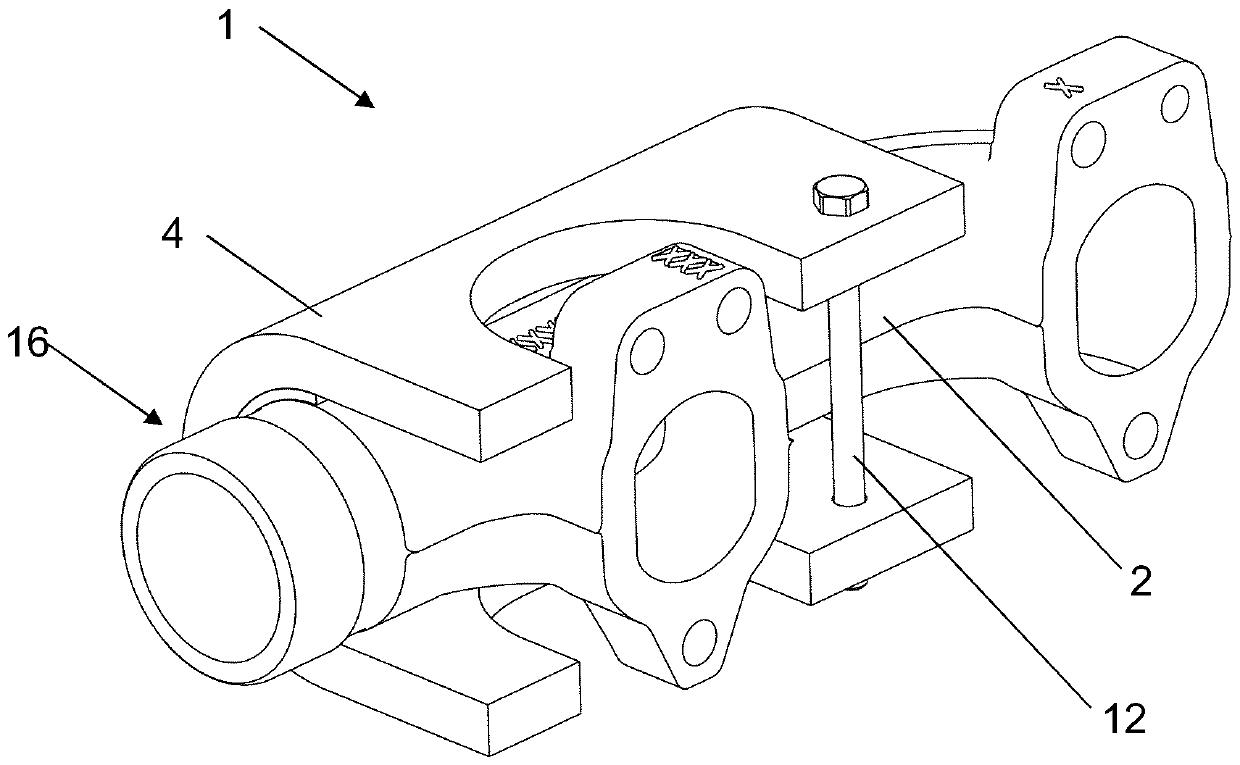

[0026] figure 1 The figure depicted in shows a three-dimensional view of an exhaust manifold 1 according to the invention with thermoelectric elements.

[0027] The illustrated embodiment shows variants in which the thermoelectric elements and cooling elements are attached on both sides, that is to say at the bottom and at the top of the exhaust manifold, but it is naturally also possible Possible embodiments of the exhaust manifold according to the invention are envisaged only at the bottom or only at the top, and only on the front side or on all sides (that is to say at the top, at the bottom and on the front side) have these elements.

[0028] exist figure 1 In the depicted embodiment, the cooling elements 4 are fastened on the exhaust manifold 2 by means of fastening means 12, wherein, in the depicted embodiment, each is arranged as one on the exhaust manifold The cooling elements 4 on the side 5 and one on the lower side 6 of the exhaust manifold are clamped together. Na

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap