Tower-type fresh milk freezing-type separation device

A separation device and technology for fresh milk, applied in milk processing equipment, other dairy products, dairy products, etc., can solve the problems of complex separator structure, inability to separate fresh milk, low separation efficiency of fresh milk and water, etc. Separation efficiency, simple device structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

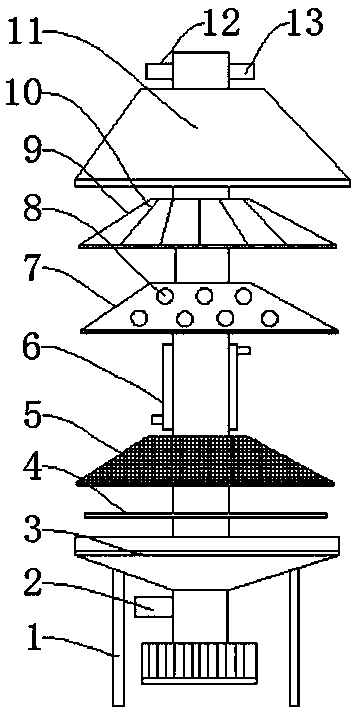

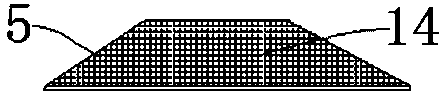

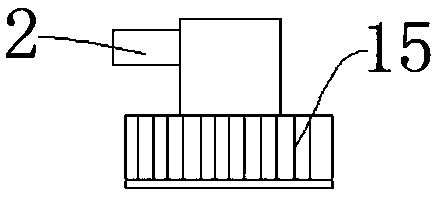

[0018] see Figure 1-3 , a tower-type fresh milk freezing type separation device, including a frame 1, an elastic sealing ring 4, a filter hole 8 and a discharge pipe 12, a feed pipe 2 is installed above the frame 1, and a separation pipe 2 is installed above the feed pipe 2 The bottom bracket 3 of the separator, the elastic sealing ring 4 is installed above the bottom bracket 3 of the separator, the trapezoidal filter cartridge 5 is arranged above the bottom bracket 3 of the separator, and the cooling passage 6 is installed above the trapezoidal filter cartridge 5, and the cooling passage 6 is composed of a draft pipe and It consists of a cooling jacket covering the outside of the draft tube; the jacket is connected to a cold water source (not shown) installed outside the frame through a circulation pipeline; a filter 7 is installed above the cooling

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap