Special hole boring mounting equipment with function of preventing hole machining deformation

A technology for installing equipment and hole processing, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem that the quality of workpiece processing is difficult to guarantee, the feed rate of boring tools is not well controlled, and the pressing position is difficult to choose. problems, to improve the processing accuracy and quality, shorten the time for disassembling and processing the workpiece, and achieve the effect of uniform distribution of the pressing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

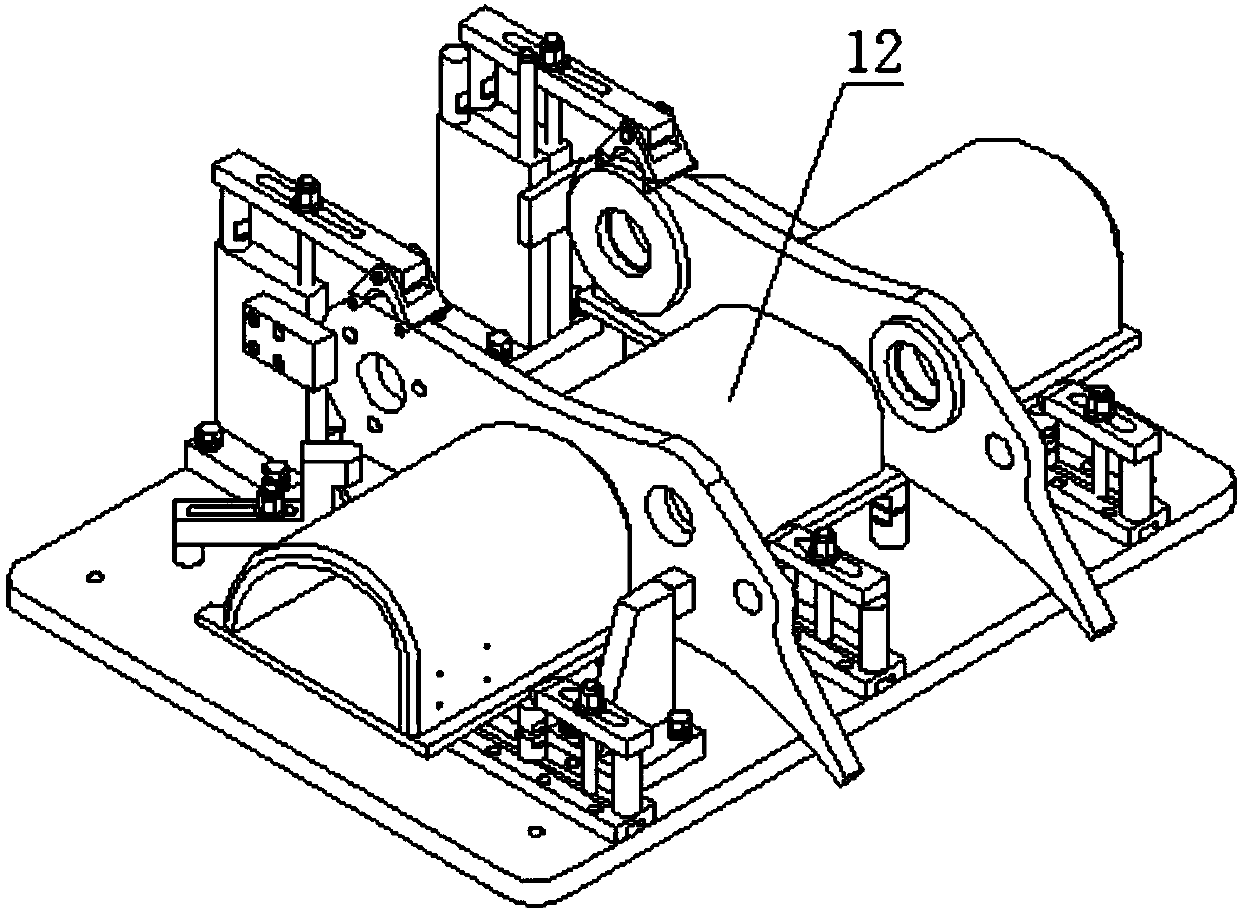

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

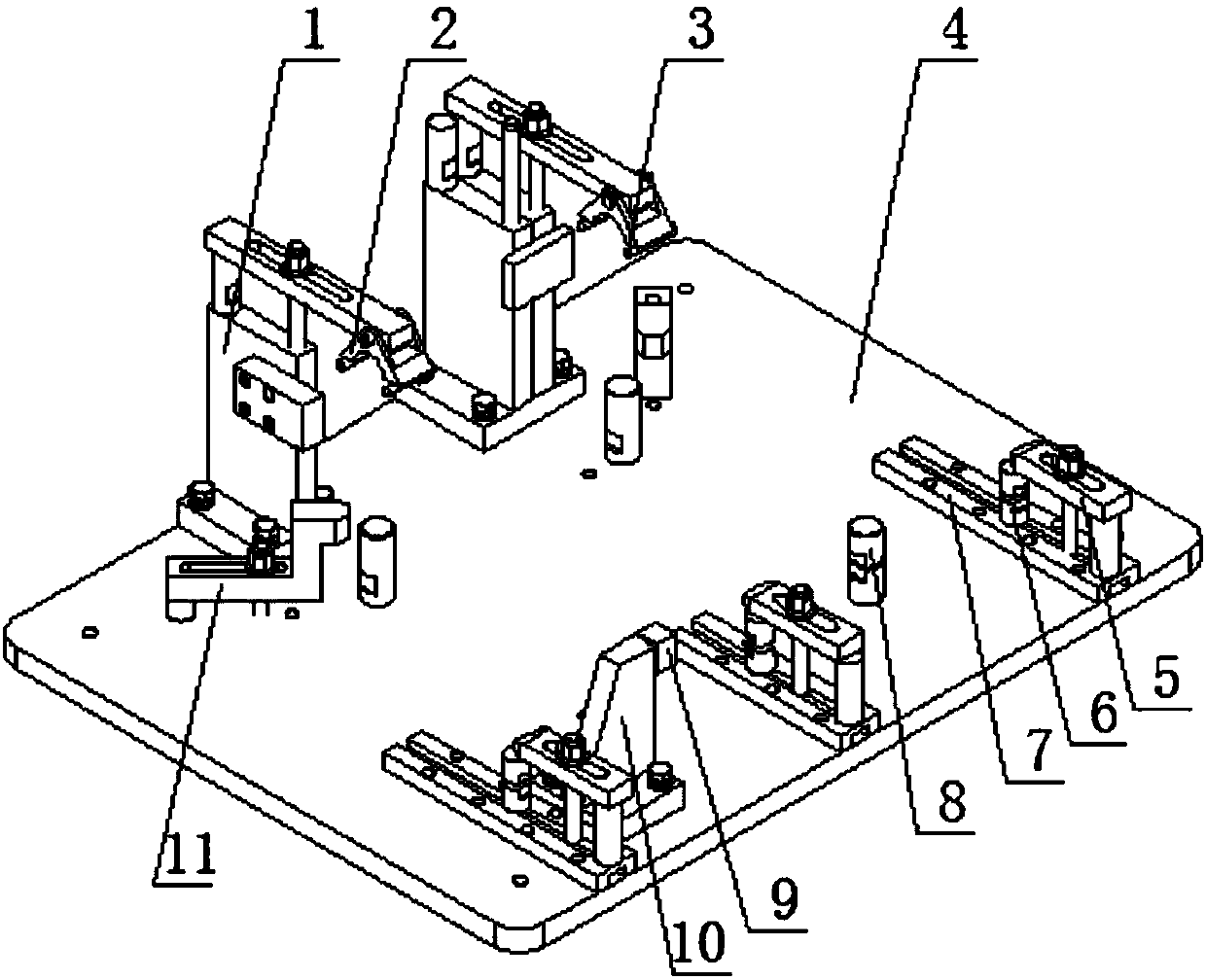

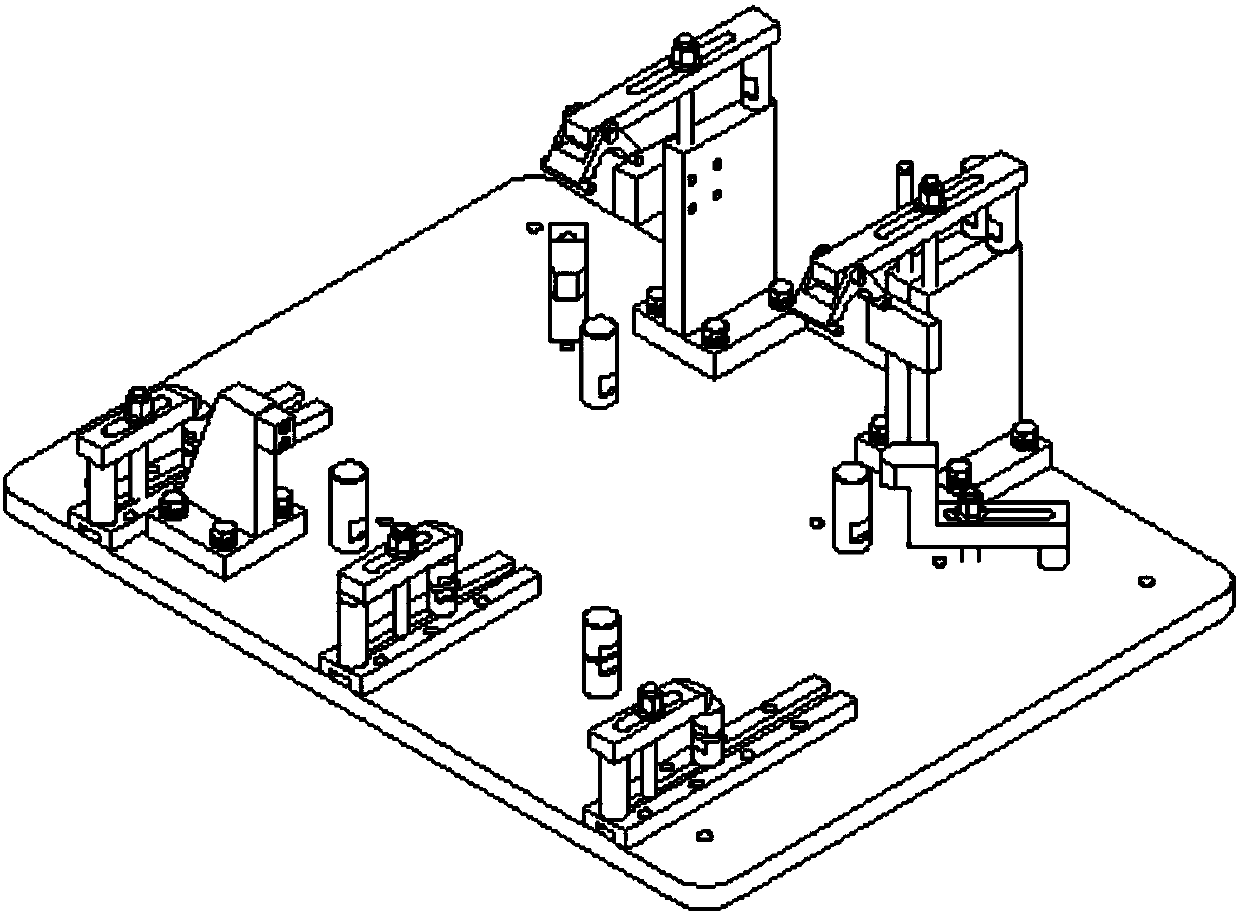

[0022] A special installation device for boring holes with the function of preventing hole processing deformation, including a bottom plate 4, a supporting post 8, a lower pressing mechanism, an upper pressing mechanism 1 and a side positioning frame. There are four posts, which are installed on the mounting holes made on the upper surface of the base plate. According to different workpiece models, the installation position of the support column can be adjusted.

[0023] The upper surface of the base plate on the outside of the support column is equipped with a lower pressing mechanism, and there are five lower pressing mechanisms, which are respectively arranged on the front and the rear of the upper surface of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap