Zero-discharge garbage disposal vehicle

A technology of garbage disposal and garbage disposal system, which is applied in the field of zero-emission garbage disposal vehicles, can solve the problems of affecting the ecological environment, damage to the surrounding environment, and the odor of garbage flying in disorder, so as to improve the efficiency of collection and transfer, reduce the incidence of failures, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

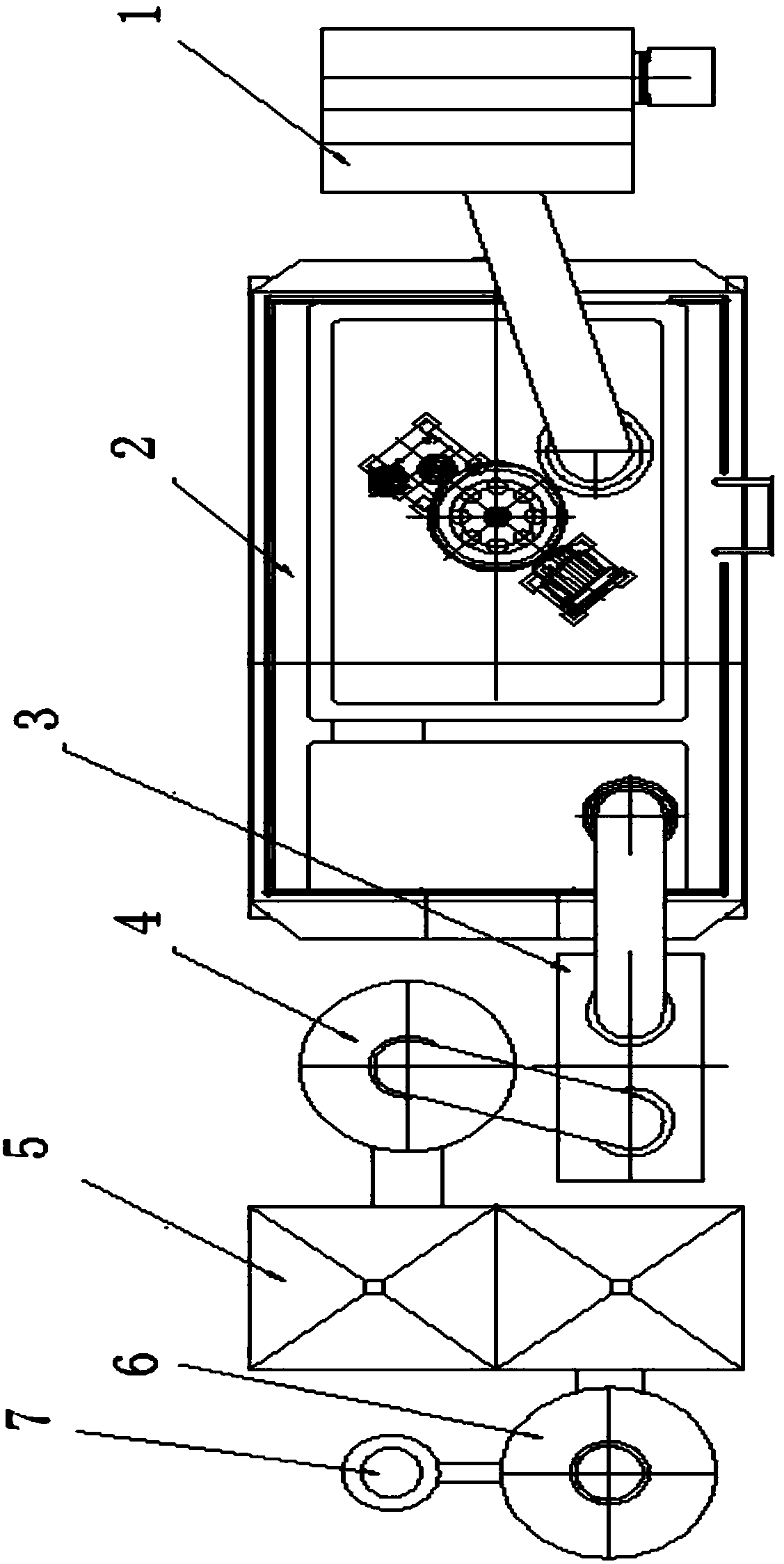

[0021] Such as figure 1 As shown, a zero-emission garbage disposal vehicle includes a vehicle body chassis on which a garbage disposal system, an electrical control system and a bucket turning mechanism are provided;

[0022] The garbage treatment system includes a crusher 1, a feeding device for transferring garbage, a collection device for collecting leachate, a burner oven 2, a first dust removal device 4, a second dust removal device 5, and a first purification device 6. And the second purification device 7;

[0023] The burner oven 2, the first dust removal device 4, the second dust removal device 5, the first purification device 6 and the second purification device 7 are connected in sequence;

[0024] The burner includes a furnace body one chamber and a furnace body two chambers, the inner temperature of the furnace body one chamber is higher than the furnace body two chambers, and the collecting device is connected with the furnace body one chamber. The temperature inside the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap