Bubble film coiled material cutting, forming and stacking device

A coil cutting and stacking device technology, which is applied in metal processing and other directions, can solve the problems of high labor intensity and increased production costs, and achieve the effect of reducing labor and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

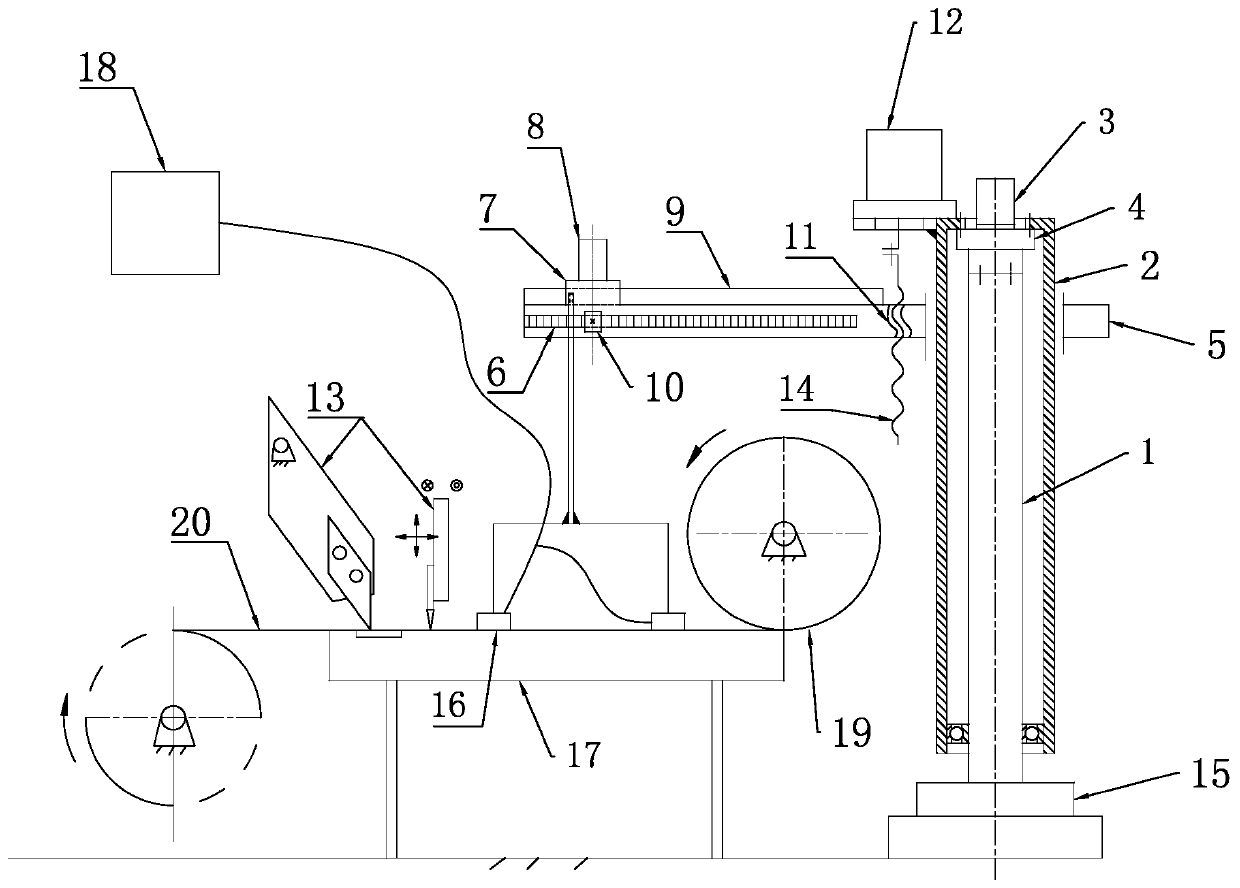

[0011] In order to further explain the technical means and effects of the present invention used to achieve the predetermined purpose, the specific implementation and structure of the foam film roll cutting and forming palletizing device proposed in accordance with the present invention will be given with reference to the accompanying drawings and preferred examples. , Characteristics and effects, detailed description is as follows.

[0012] See figure 1 , A foam film coil cutting and forming palletizing device, comprising a base 15, a sleeve 2, a first servo motor 3, an RV reducer 4 and a column 1 fixed on the base 15, and the sleeve 2 is sleeved on the column 1 On the outside, the column 1 and the sleeve hole 2 are connected by a bearing, the inner ring of the bearing is fixed to the column 1, the outer ring of the bearing is fixed to the sleeve 2, and the RV reducer 4 is fixed to the top of the column 1. The output shaft of the first servo motor 3 is connected to the input end o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap