Stepped plate type pile foundation permeable breakwater

A technology of breakwaters and stepped slabs, which is applied in the field of marine engineering, can solve the problems that the force of the breakwater structure has not been effectively reduced, the wave dissipation effect of the breakwater needs to be improved, and the force-bearing area of the plate is large, so as to achieve simple construction and wave dissipation. Good effect and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that this embodiment is only used to illustrate the present invention and is not used to limit the protection scope of the present invention. In addition, it should be understood that after reading the content of the present invention, various equivalent changes and modifications made by those skilled in the art to the present invention fall within the scope defined by the patent claims of this application.

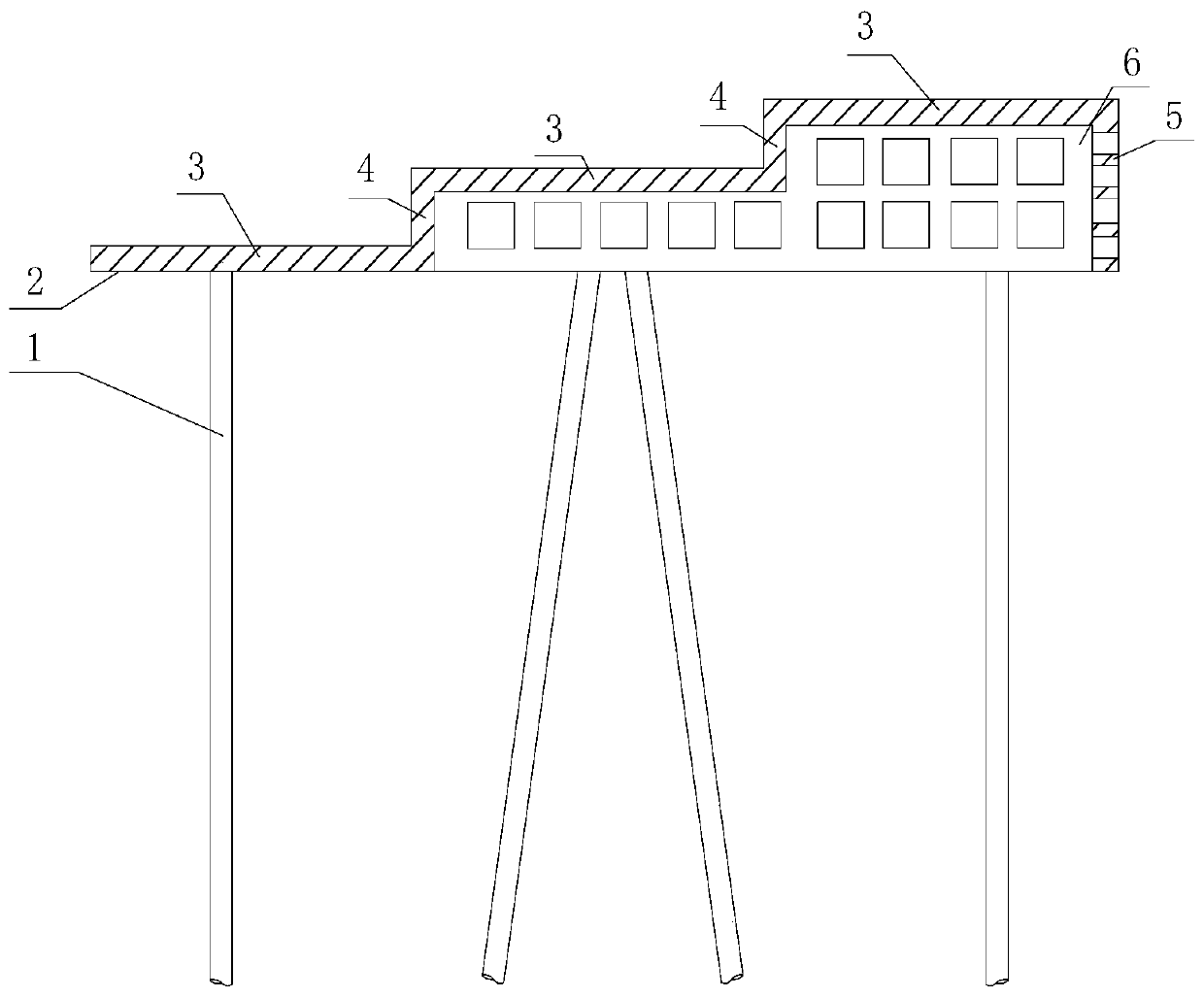

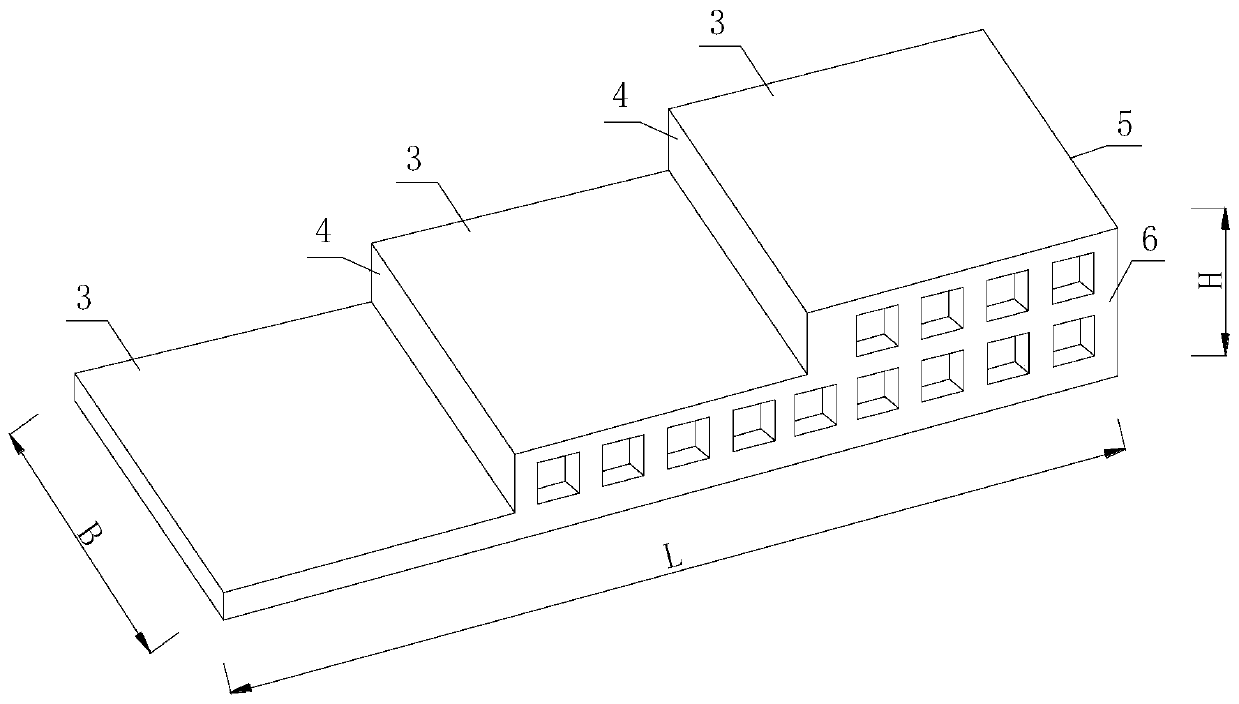

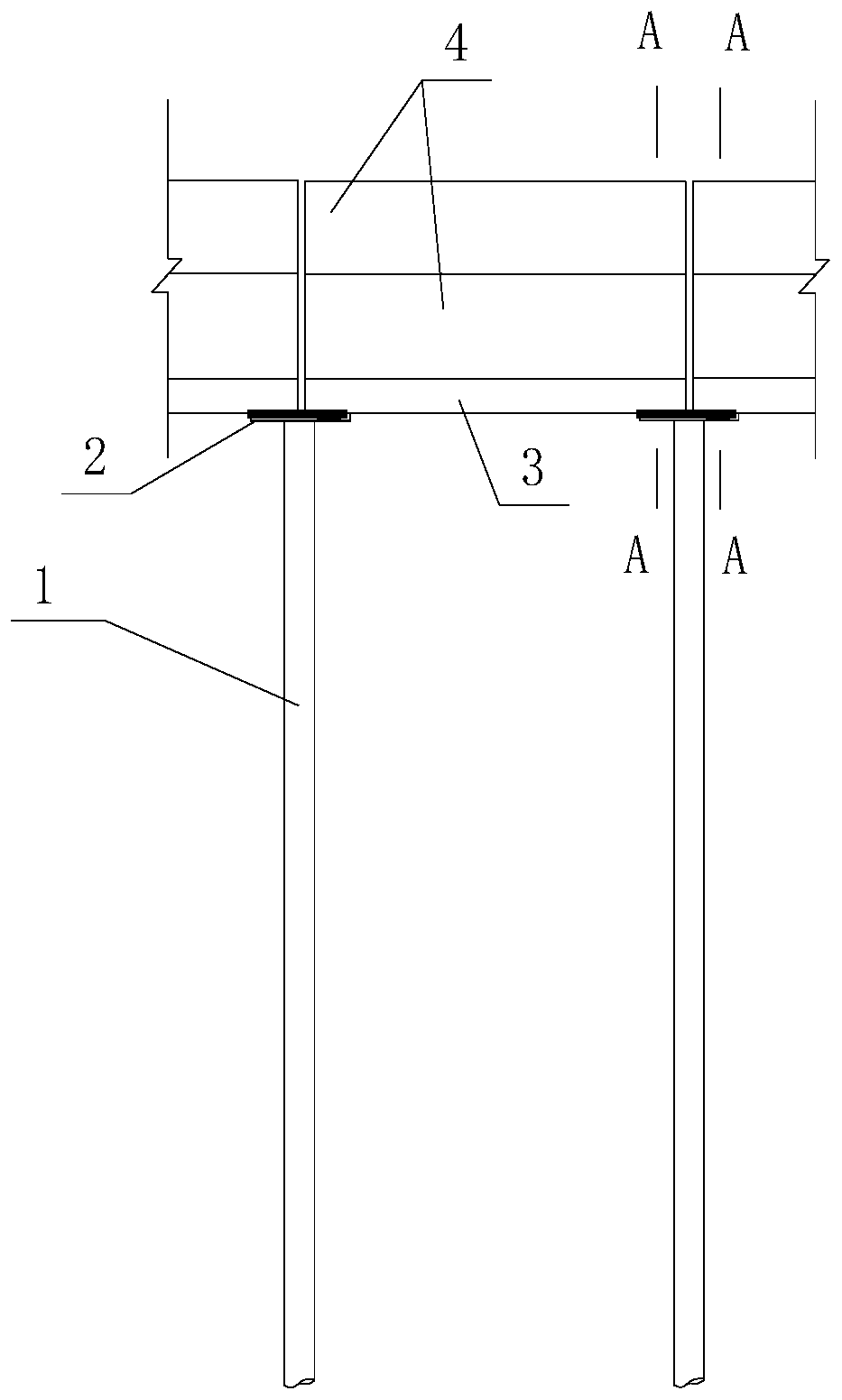

[0033] Such as figure 1 , Figure 3-Figure 5 The cross-sectional structure diagram and the left view, the three-dimensional view of the steel beam, and the A-A cross-sectional structure diagram of a stepped slab pile foundation permeable breakwater of the present invention are respectively shown. The stepped slab pile foundation permeable breakwater of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap