Zipper lining furnace tank

A zipper and furnace lining technology, applied in furnaces, electric furnace heating, furnace components, etc., can solve the problems of imperfection and imperfection, hinder the integration of new technologies into the market, etc., and achieve the effect of lowering the price, reducing the consumption, and saving electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

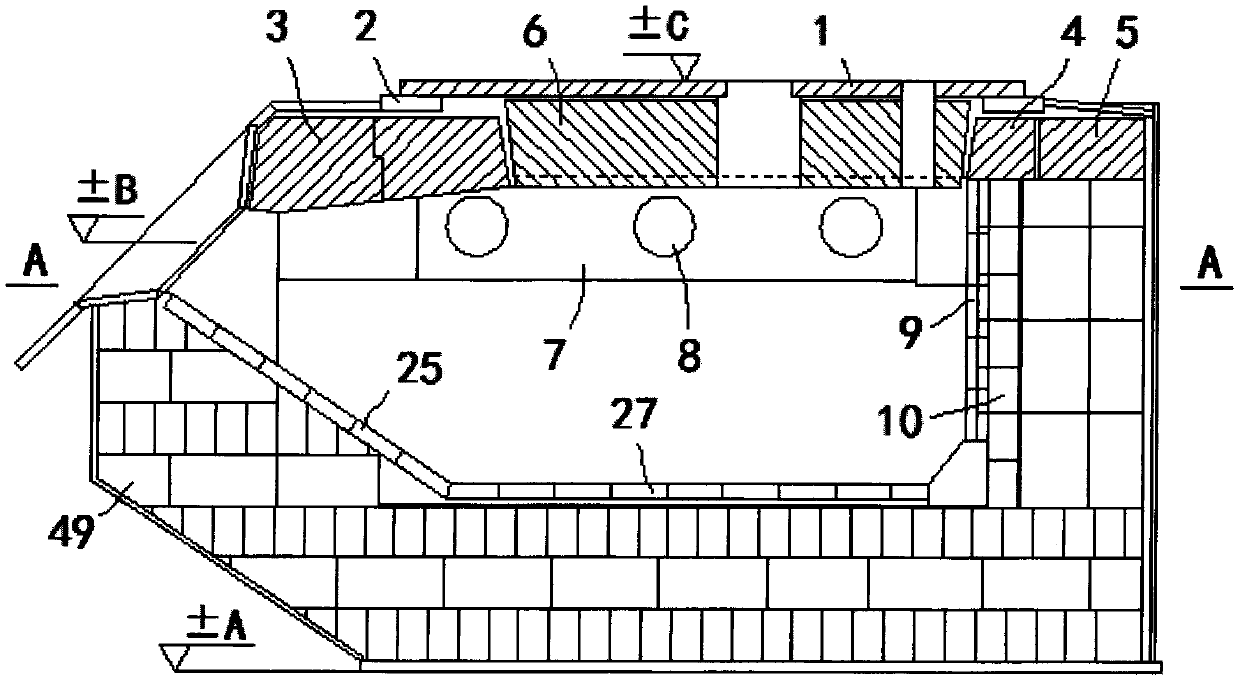

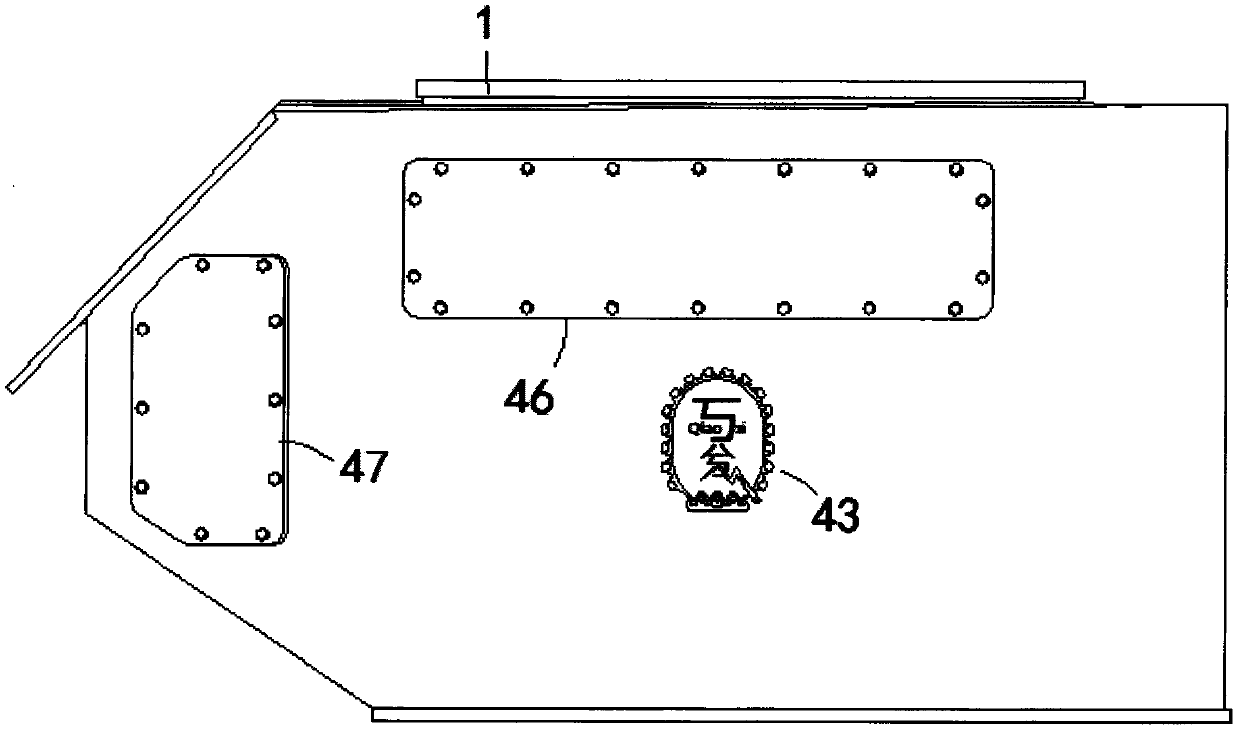

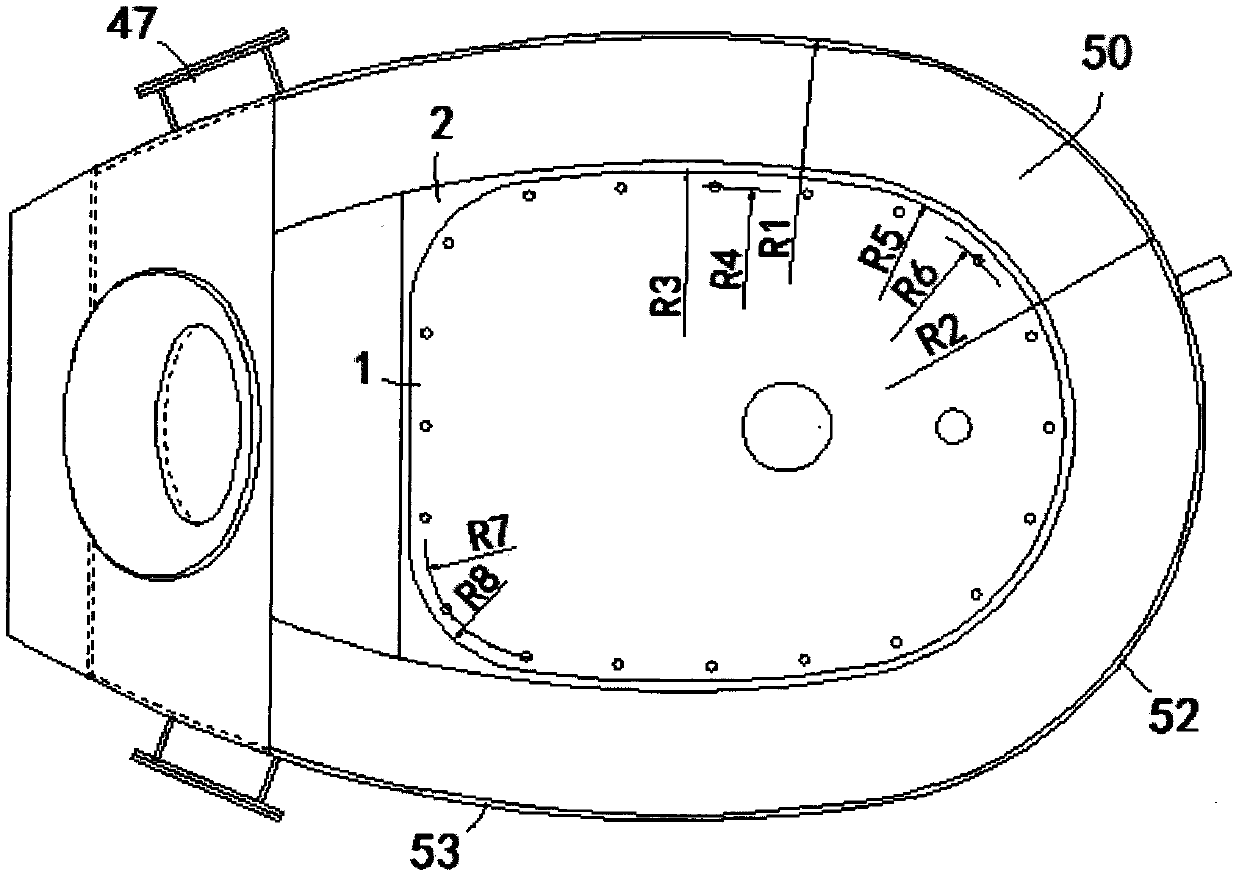

[0034] The accompanying drawings are now described further with reference to the accompanying drawings. attached Figure 1-20 Shown is the general idea of the present invention, wherein appended Figure 1-12 Shown is a technical scheme in the general concept of the present invention, Figure 1-8 Shown is a specific embodiment of the overall structure of the tooth occlusal lining die-casting furnace in this technical solution, Figure 9-12 Shown in this specific embodiment, the main part of the furnace tooth engagement chain combined wall ring, the general shape and size of the used shaping materials and the relevant furnace shell size model, and the determination of the size model and the method of model expansion. attached Figure 13-21 Shown is another specific embodiment of the technical solution of the general concept of the present invention,

[0035]1-8 in the accompanying drawings is a specific embodiment of the die-casting technical solution for tooth occlusal linin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap