Electrode cylinder

A technology of electrode cylinder and cylinder, which is applied in the direction of ohmic resistance electrode, electric furnace heating, ohmic resistance heating parts, etc., can solve the problems of high electrode failure rate, slow electrode roasting, low electrode strength, etc., achieve good quality and reduce failure The effect of high rate and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

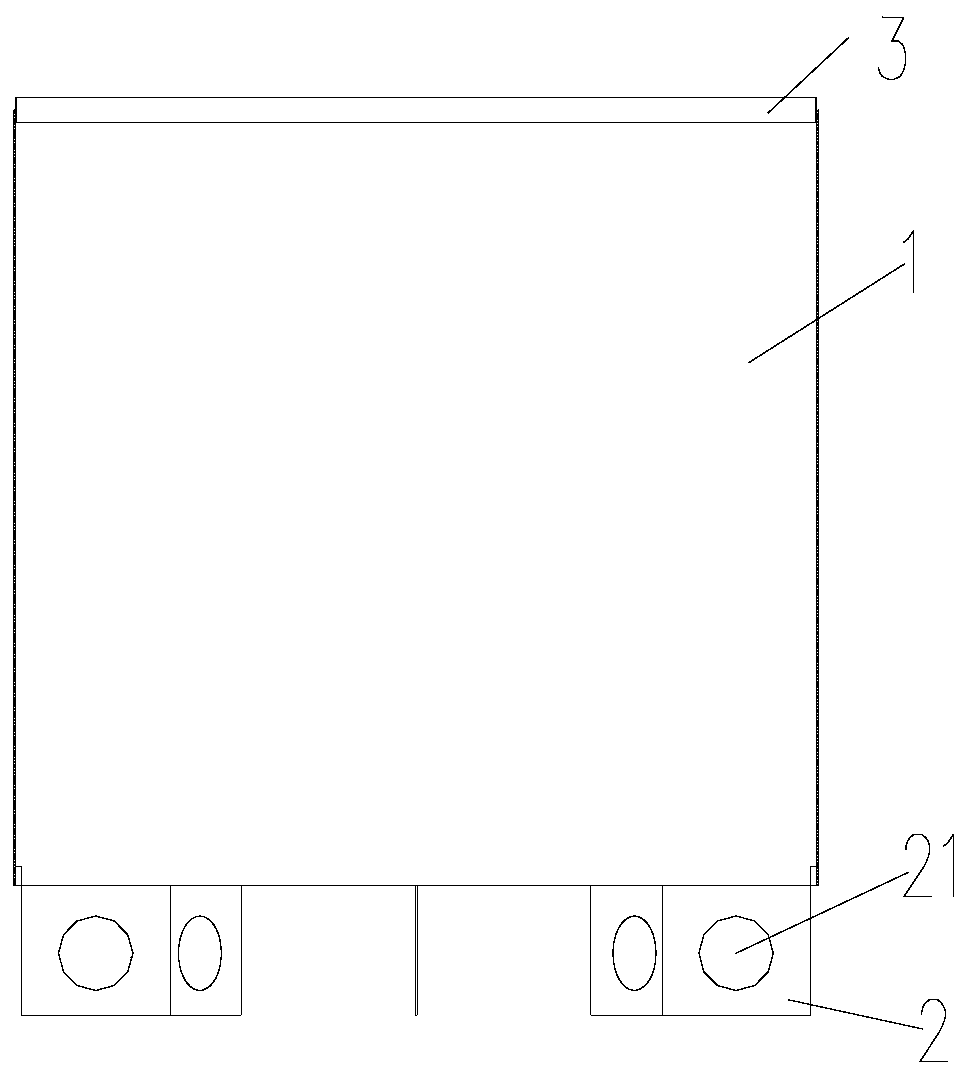

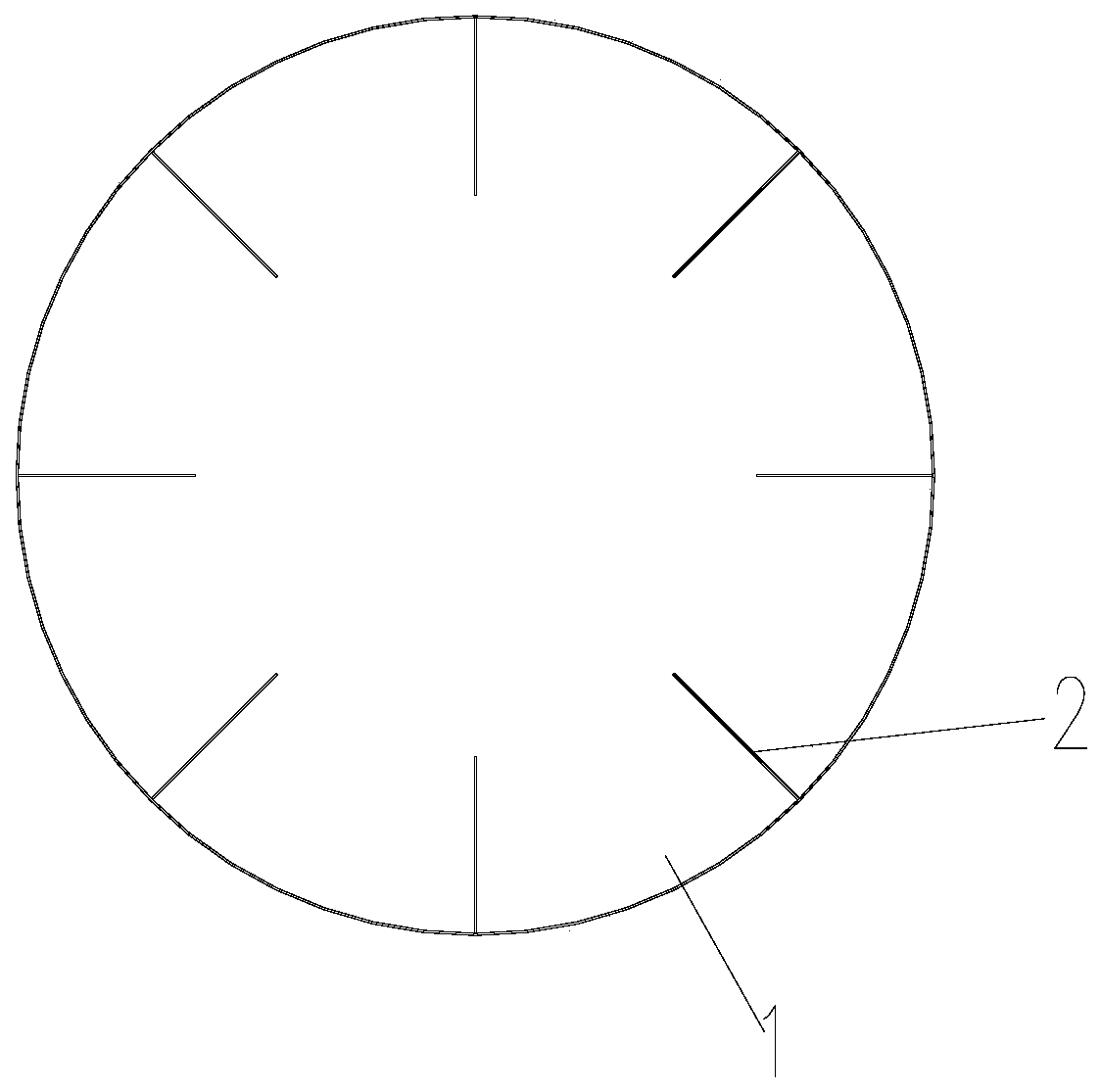

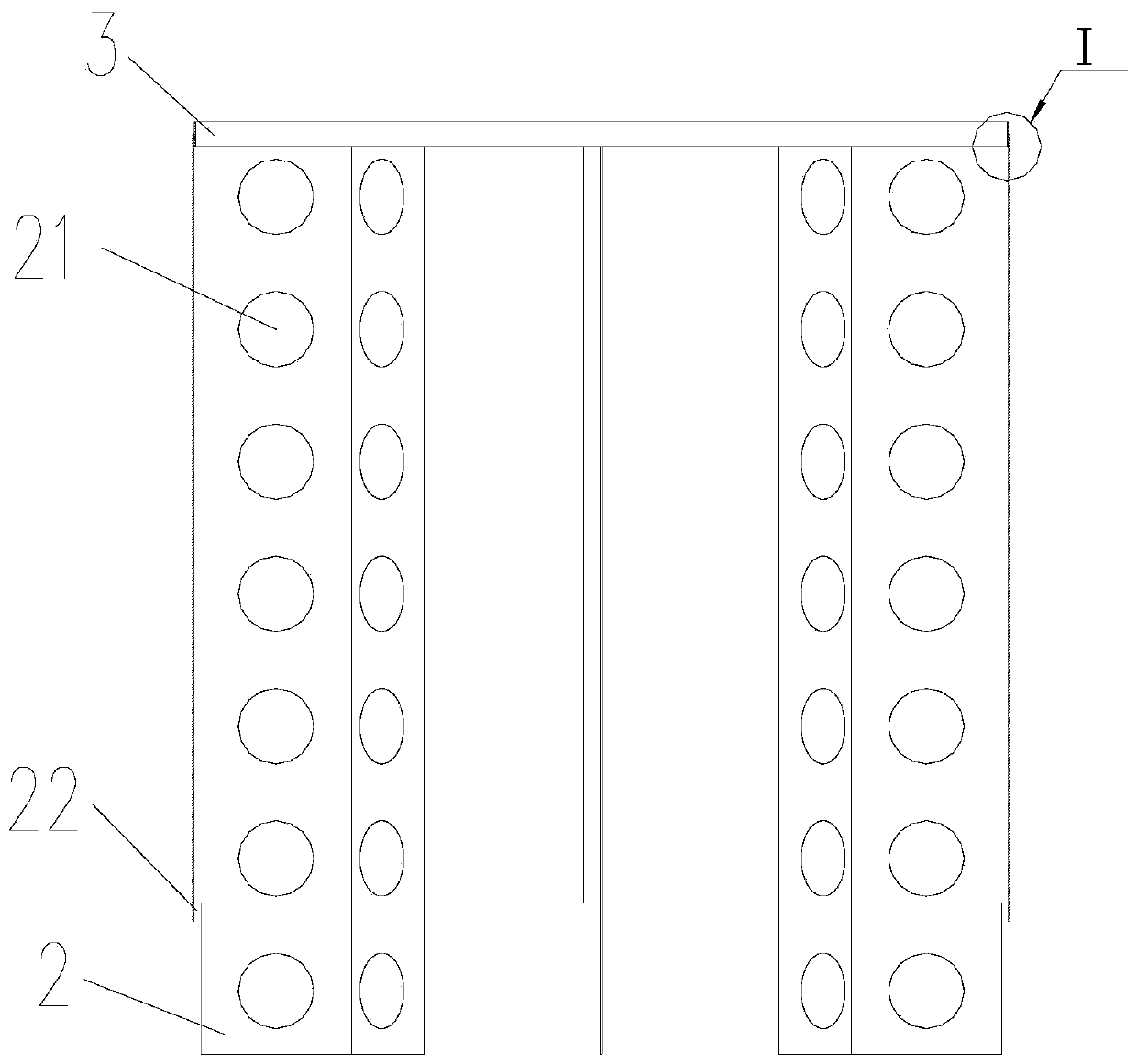

[0025] reference Figure 1-6 , The present invention provides an electrode cylinder, which is located in a submerged arc furnace, and a plurality of electrode cylinders are connected in series. In metal smelting, the electrode paste inside is sintered into electrodes. The electrode cylinder includes a cylindrical shape. The inner surface of the cylinder 1 is uniformly provided with a plurality of ribs 2 in the radial direction, so that the angle between the plurality of ribs 2 is constant, and the inner area of the cylinder 1 can be evenly divided into multiple parts. The ribs 2 arranged in this way can make the heating more uniform and the heating sp

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap