Stainless steel pipe with deviation preventing function

A stainless steel, anti-migration technology, applied in pipeline systems, pipes, rigid pipes, etc., can solve the problems of easy offset, use entanglement, and the connection of stainless steel pipes is not firm enough, so as to improve convenience, shorten query time, The effect of enhancing the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

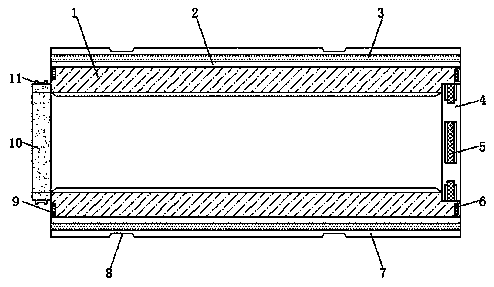

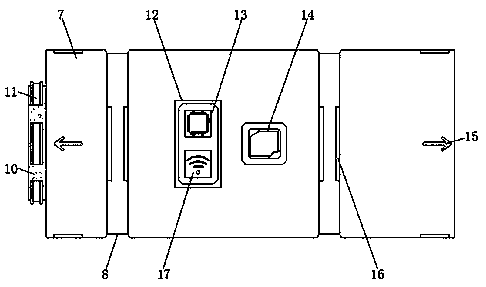

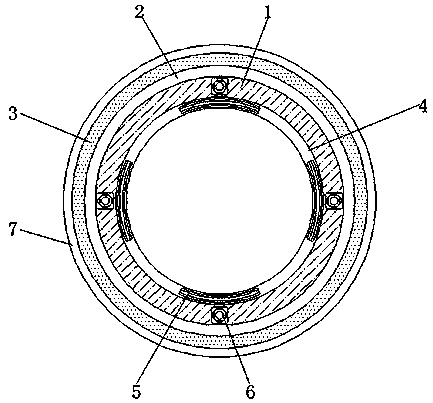

[0024] see Figure 1-4 , an embodiment provided by the present invention: a stainless steel pipe with anti-offset function, including a pipe base layer 1, an anti-seepage layer 2, a reinforcement layer 3, a clip 10 and an indicator arrow 15, on the outer wall of the pipe base layer 1 An anti-seepage layer 2 is provided, and the surface of the anti-seepage layer 2 away from the pipeline base layer 1 is provided with a reinforcing layer 3, and the outer walls of bo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap