Ball head joint finger mechanism with flexible connection and hydraulic drive

A technology of flexible connection and ball joints, applied in the direction of joints, chucks, manipulators, etc., can solve the problems of excessive finger joint structure, finger joint flexibility and driving force, etc., and achieve the effect of flexible movement, compact structure and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

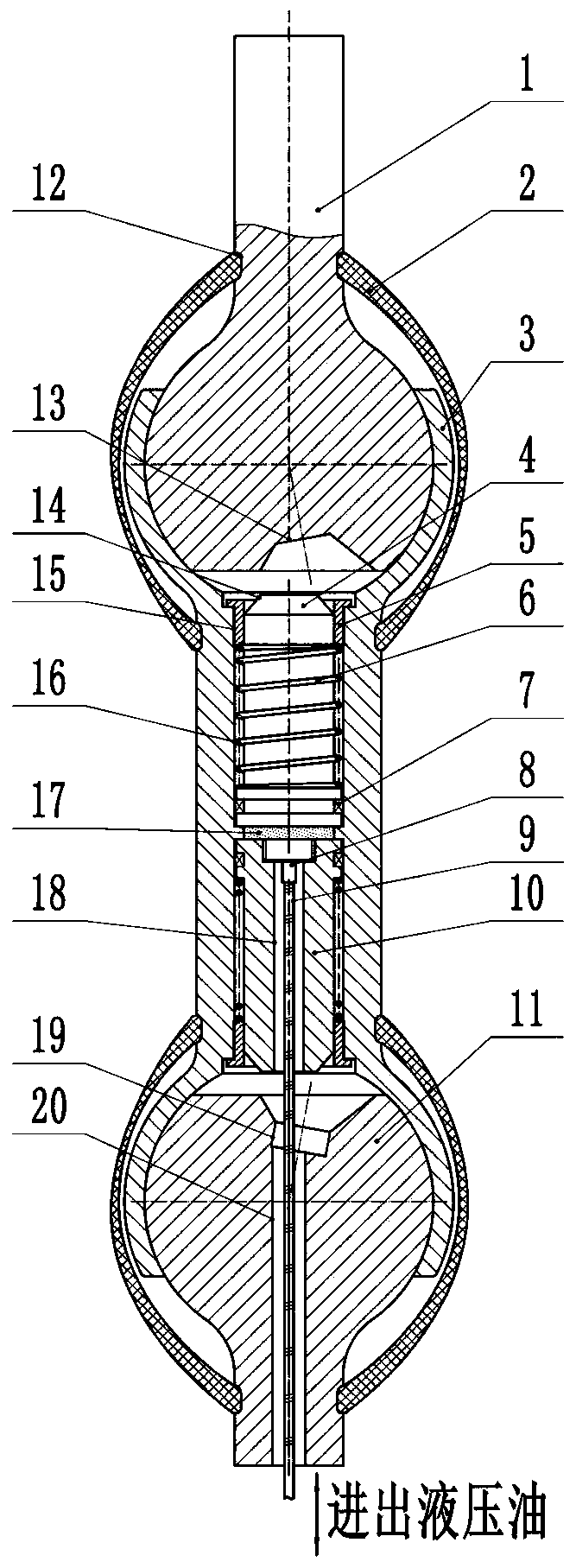

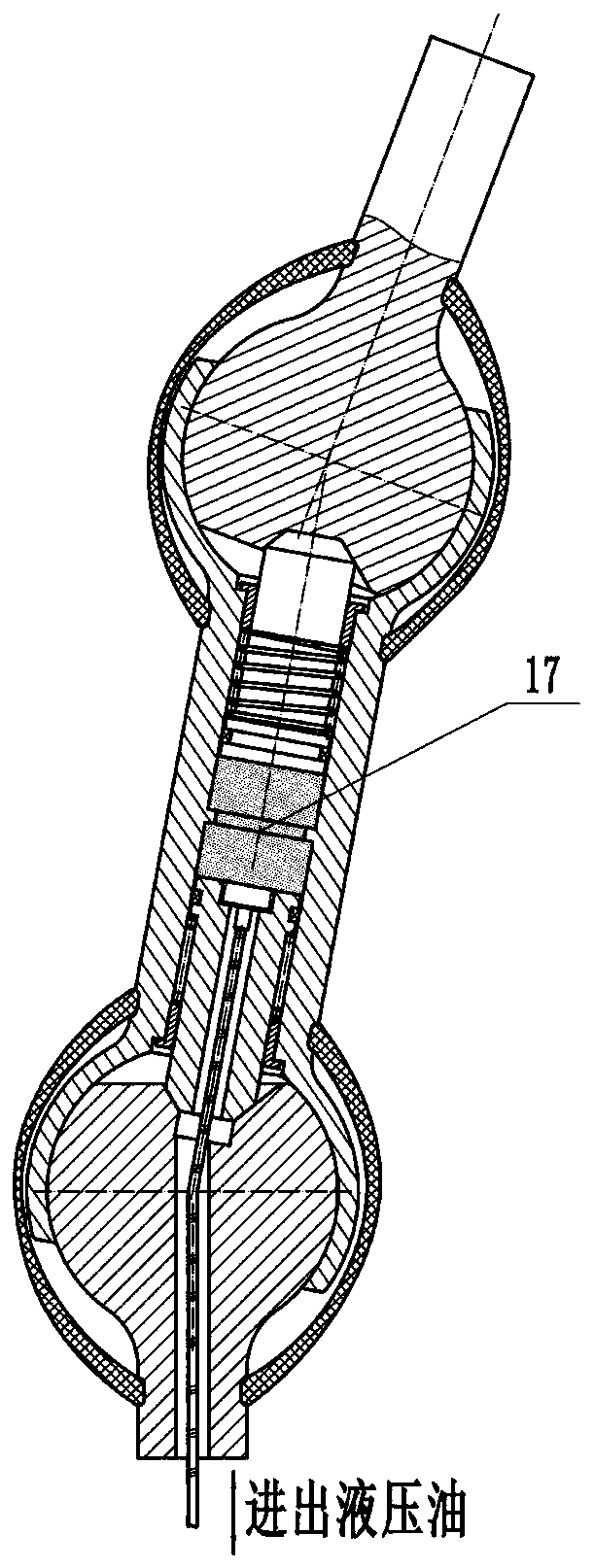

[0033] like Figures 1 to 5 As shown, the flexible connection and hydraulically driven ball joint finger mechanism of the present invention includes: a three-bar two-joint mechanism, a hydraulically driven locking mechanism, and a flexible connection mechanism; wherein:

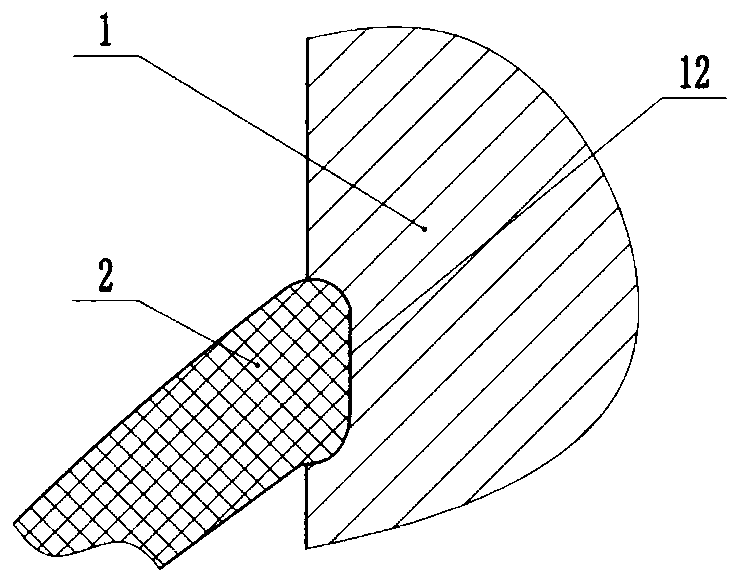

[0034] The three-bar two-joint mechanism includes two ball ends (upper ball head 1, lower ball head 11) and a ball socket 3 between the two ball ends. The two ball ends are respectively The first ball head, the second ball head;

[0035] Both the first ball head and the second ball head are rods with a ball head at one end, and the ball end of the first ball head and the ball end of the second ball head are both provided with a tapered groove 13 At the same time, the second ball head is provided with a ball head through hole 20, one end of the ball head through hole communi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap