Chicken manure fermentation composting method based on diaphragm type aeration treatment

A composting method and membrane-type technology are applied in the directions of organic fertilizers, fertilization devices, excretion of fertilizers, etc., which can solve the problems of shortening the fermentation and decomposing time of chicken manure, incomplete fermentation and decomposing of chicken manure, etc., and achieve a good effect of harmless treatment. Quick and easy on-site acquisition, complete manure curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for fermenting and composting chicken manure based on membrane aeration treatment, comprising the steps of:

[0038] 1) Build an aerated fermentation bed:

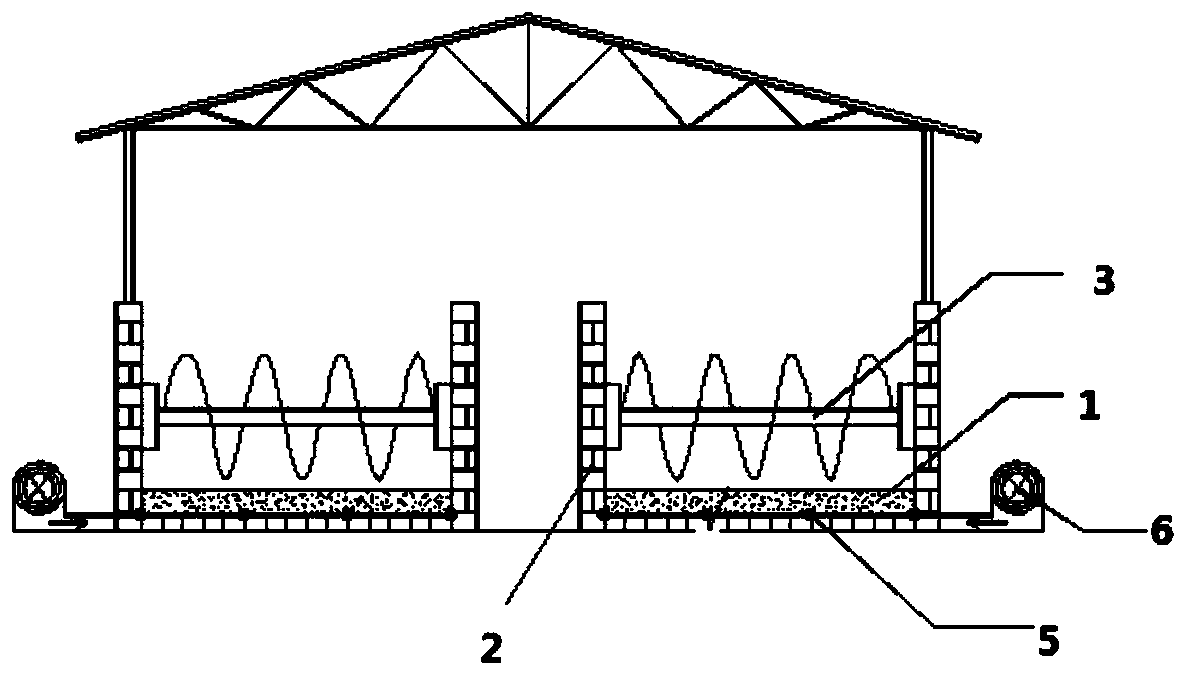

[0039] (11) Build 4m (width) × 2m (depth) 2 fermentation beds that are rain-proof, leak-proof, and can be shifted back and forth in both directions (see figure 1 ), the length of the fermentation bed is set according to the scale of the farm;

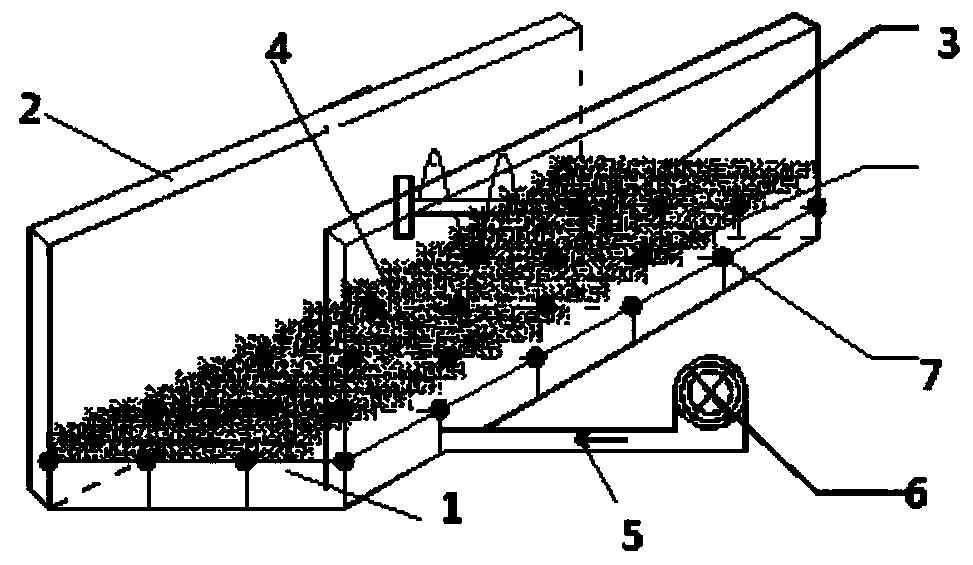

[0040] (12) Diaphragm aeration device design: fix baffles 2 on both sides of the support plate 1, and install a throwing machine 3 between the two baffles 2; insert a field-shaped pattern on the support plate 1, with an inner diameter of 20mm The aeration hose 4 is provided with an aeration membrane 7 at the 1m × 1m joint of the aeration hose 4 at every interval, and two air delivery pipes 5 are connected to the middle part outside the fermentation bed, and are connected with the high-pressure air pump 6 ( See figure 2 );

[0041] 2) design of aeration and slow pre

Embodiment 2

[0046] A method for fermenting and composting chicken manure based on membrane aeration treatment, comprising the steps of:

[0047]1) Build an aerated fermentation bed:

[0048] (11) Build 4m (width) × 2m (depth) 2 fermentation beds that are rain-proof, leak-proof, and can be shifted back and forth in both directions (see figure 1 ), the length of the fermentation bed is set according to the scale of the farm;

[0049] (12) Diaphragm aeration device design: fix baffles 2 on both sides of the support plate 1, and install a throwing machine 3 between the two baffles 2; insert a field-shaped pattern on the support plate 1, with an inner diameter of 20mm The aeration hose 4 is provided with an aeration membrane 7 at the 1m × 1m joint of the aeration hose 4 at every interval, and two air delivery pipes 5 are connected to the middle part outside the fermentation bed, and are connected with the high-pressure air pump 6 ( See figure 2 );

[0050] 2) aeration and slow pressure desig

Embodiment 3

[0055] A method for fermenting and composting chicken manure based on membrane aeration treatment, comprising the steps of:

[0056] 1) Build an aerated fermentation bed:

[0057] (11) Build 4m (width) × 2m (depth) 2 fermentation beds that are rain-proof, leak-proof, and can be shifted back and forth in both directions (see figure 1 ), the length of the fermentation bed is set according to the scale of the farm;

[0058] (12) Diaphragm aeration device design: fix baffles 2 on both sides of the support plate 1, and install a throwing machine 3 between the two baffles 2; insert a field-shaped pattern on the support plate 1, with an inner diameter of 20mm The aeration hose 4 is provided with an aeration membrane 7 at the 1m × 1m joint of the aeration hose 4 at every interval, and two air delivery pipes 5 are connected to the middle part outside the fermentation bed, and are connected with the high-pressure air pump 6 ( See figure 2 );

[0059] 2) aeration and slow pressure desi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap