Automatic packaging equipment for quick-frozen food

A technology for automatic packaging and quick-frozen food, applied in the directions of packaging, packaging sterilization, transportation and packaging, it can solve problems such as surface cracks and affect sales, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

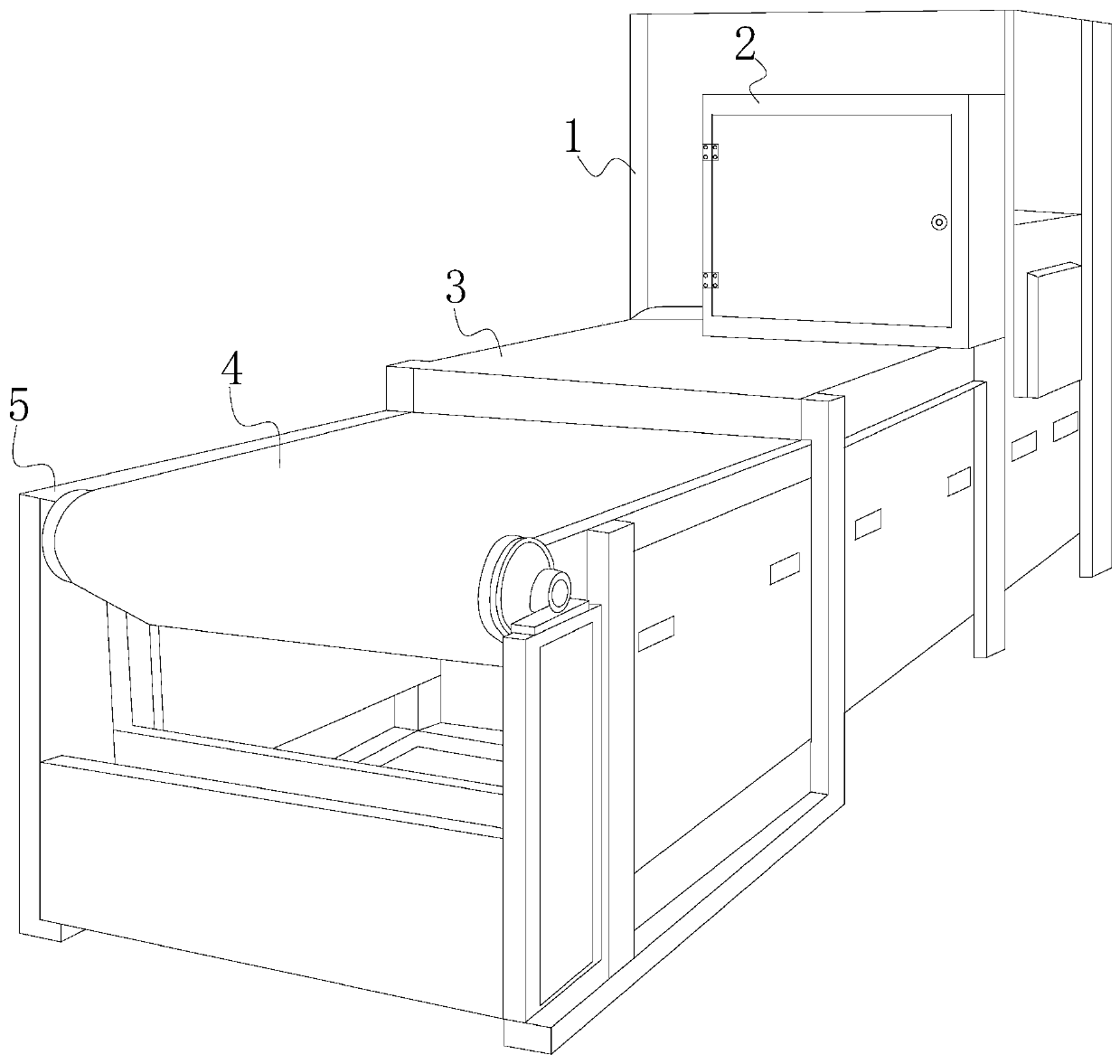

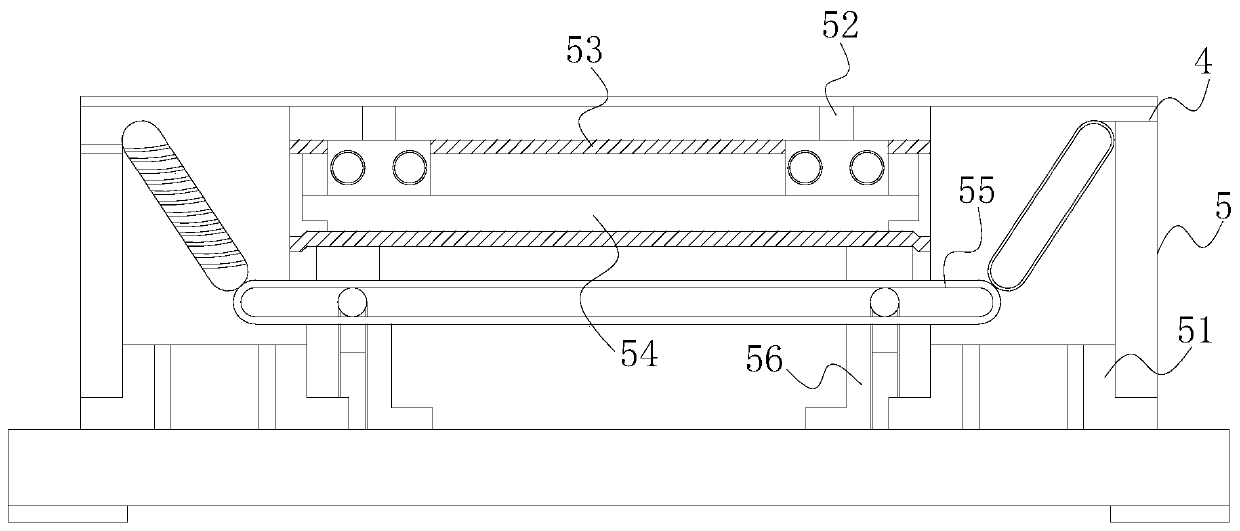

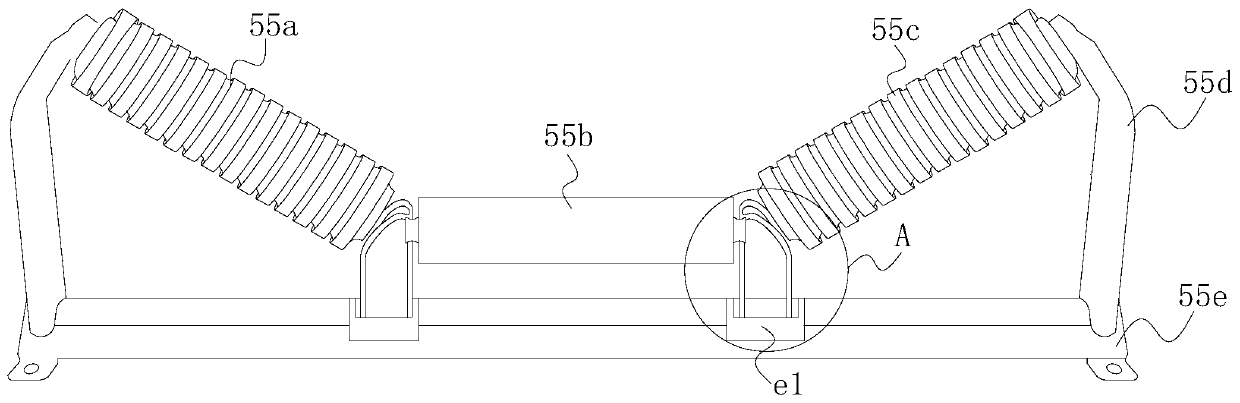

[0019] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of quick-frozen food automatic packaging equipment, and its structure comprises machine cover 1, electric control box 2, cover plate 3, conveyor belt 4, machine frame 5, and described electric control box 2 is welded and fixed on the bottom of machine cover 1 At the front end, the cover plate 3 is fixed on the bottom of the electric control box 2, and the conveyor belt 4 is connected and installed between the machine frames 5, and the machine frame 5 is matched with the inside of the machine cover 1 to be provided with a shock-absorbing base 51, clamping Mounting piece 52, lead screw 53, ultraviolet lamp tube 54, slow-down transmission mechanism 55, fixed base 56, described damping base 51 is symmetrically distributed on the left and right sides of machine frame 5, and described clamping mounting piece 52 is provided with two One, and mechanically connected with the lead screw 53, the clamping mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap