Method for improving dispersibility of n-propyltriethoxysilane

A technology of n-propyltrialkoxysilane and propyltrialkoxysilane, which is applied in the field of improving the dispersion of n-propyltrialkoxysilane, and can solve the problem of high economic cost of blending and affecting the waterproof performance of structures , Poor durability of concrete and other issues, to achieve low economic cost, improve weather resistance and durability, and maintain air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

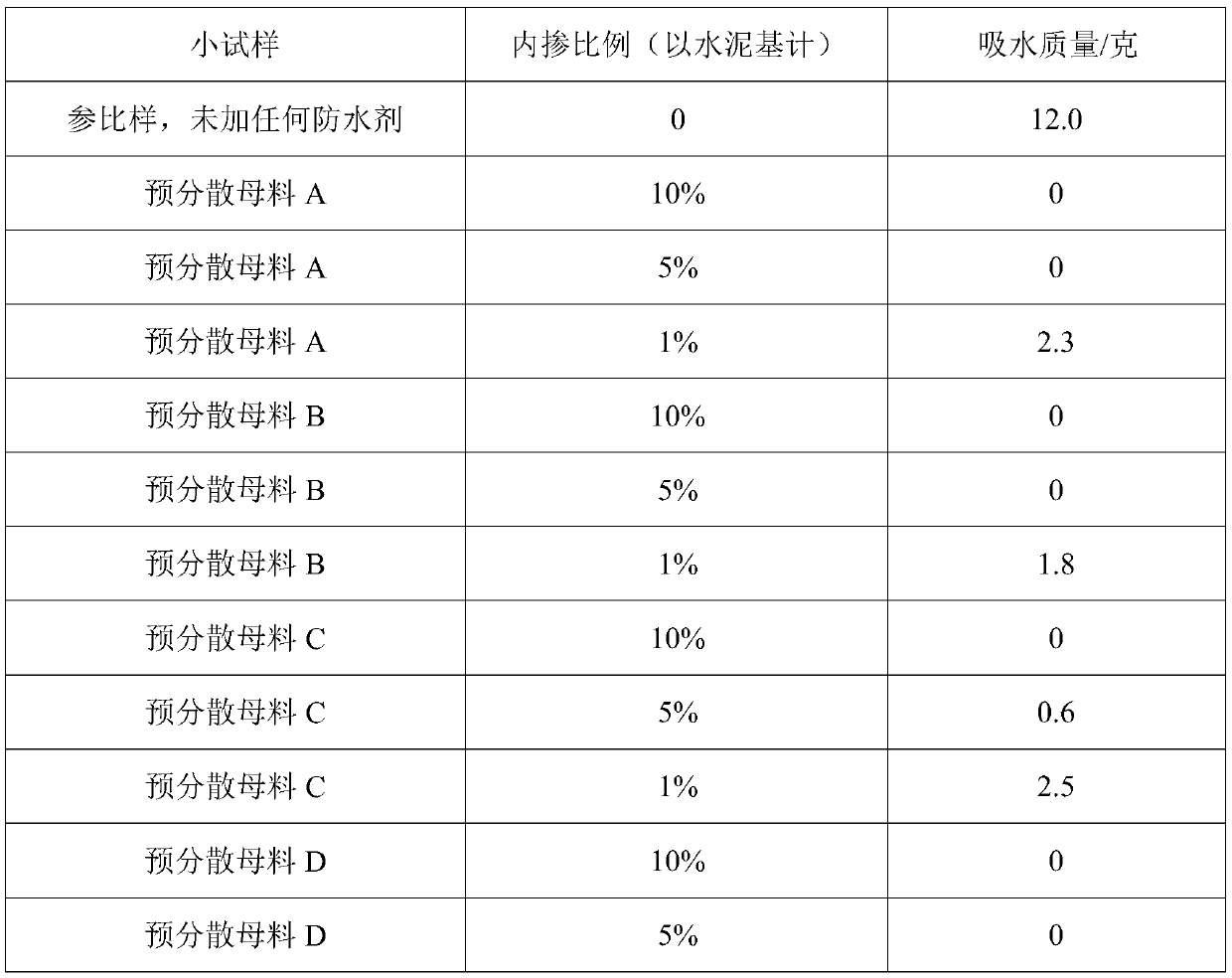

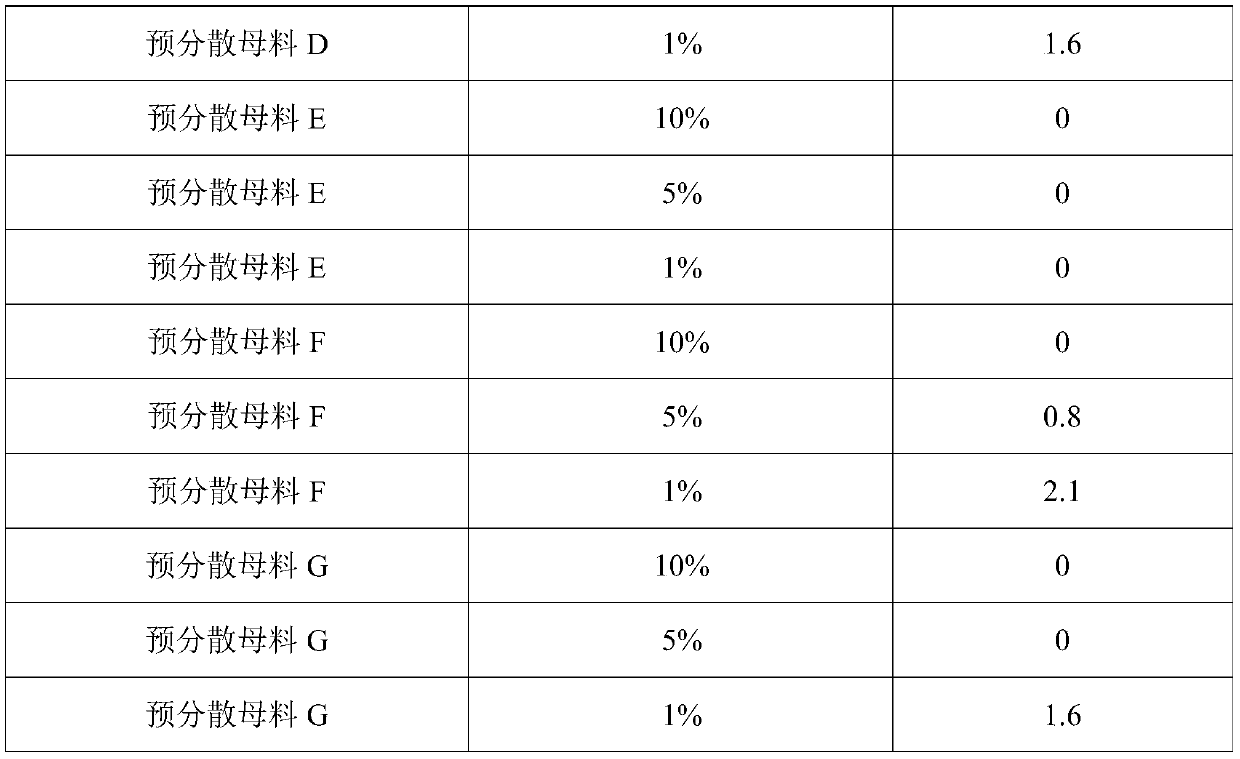

Embodiment 1

[0033] Ingredients: 10kg of n-propyltriethoxysilane, 10kg of precipitated white carbon black.

[0034] Mixing: Add the precipitated white carbon black into the 50L high-speed mixer at one time, cover the lid, open the exhaust port, then turn on the stirring, spray n-propyltriethoxysilane through the spray port, and finish spraying in 10 minutes , and continue to stir for 2 minutes to obtain pre-dispersed masterbatch A.

Embodiment 2

[0036] Ingredients: n-propyltrimethoxysilane 15kg, precipitated white carbon black 10kg.

[0037] Mixing: Add the precipitated white carbon black into the 50L high-speed mixer at one time, cover the lid, open the exhaust port, then turn on the stirring, spray n-propyltrimethoxysilane through the spray port, and finish spraying in 10 minutes. Continue stirring for 2 minutes to obtain pre-dispersed masterbatch B.

Embodiment 3

[0039] Ingredients: n-propyltriethoxysilane 100kg, calcium carbonate 120kg.

[0040] Mixing: Add calcium carbonate to the double-helix conical mixer at one time, then turn on the motor, spray n-propyltriethoxysilane through the spray port, and run the motor for 8 minutes to complete the mixing to obtain pre-dispersed masterbatch C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap