Method and system for measuring uniform elongation of pipeline steel

A technology of pipeline steel and elongation rate, which is applied in the direction of testing the ductility of materials, measuring devices, and using stable tension/pressure to test the strength of materials, etc. It can solve the problems of low accuracy, expand the range, and ensure accurate fitting The effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

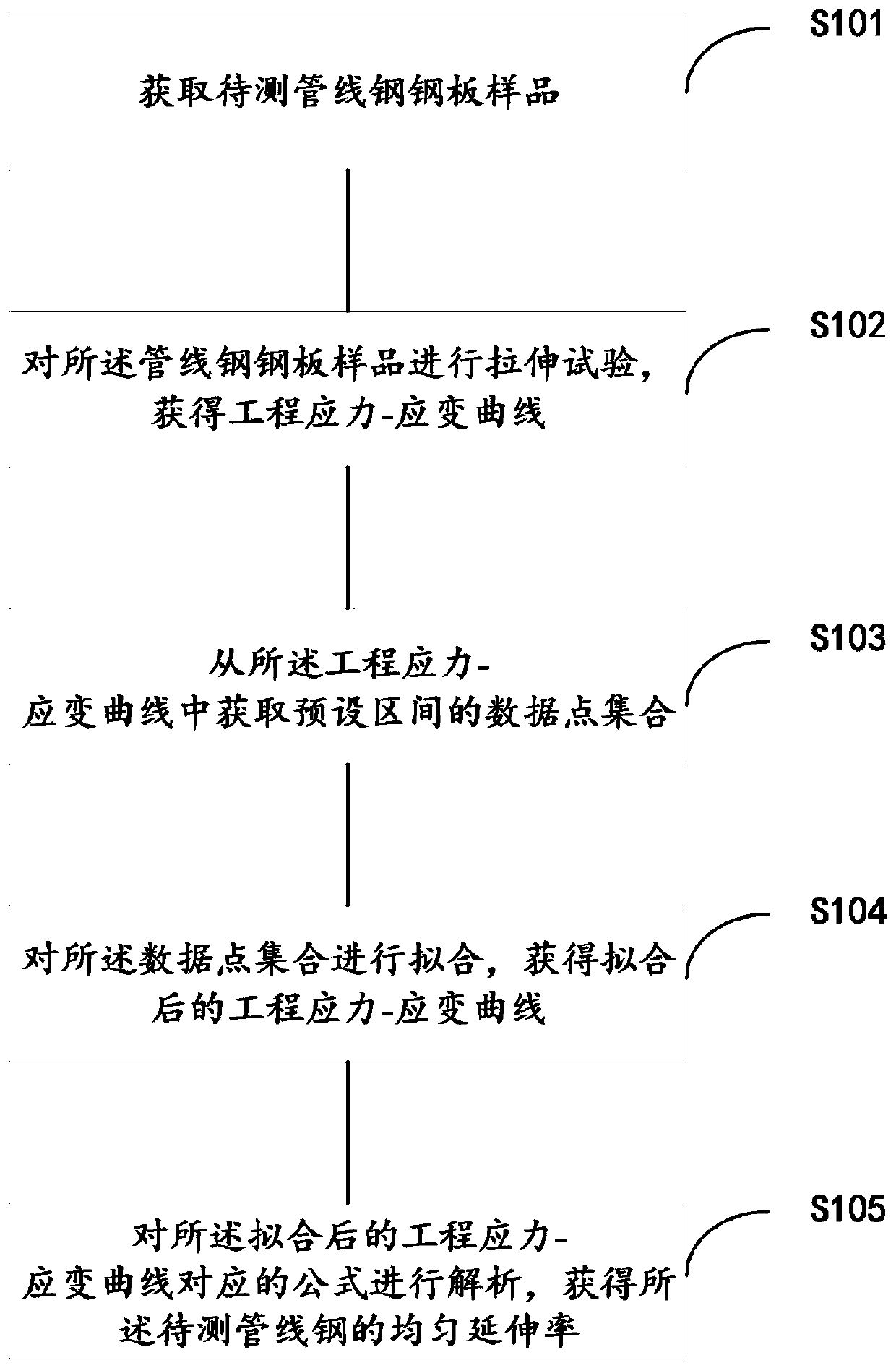

[0042] In this embodiment, a method for measuring the uniform elongation of pipeline steel, see figure 1 , the method includes the following steps:

[0043] S101. Obtain a sample of the pipeline steel plate to be tested;

[0044] S102. Perform a tensile test on the pipeline steel plate sample to obtain an engineering stress-strain curve;

[0045] S103. Obtain a set of data points in a preset interval from the engineering stress-strain curve; wherein, the starting point of the preset interval is the data point corresponding to a strain of 0.5%, and the end point is the strain value corresponding to the maximum stress value increased by 1 The data point corresponding to the -2% strain point;

[0046] S104. Fitting the set of data points to obtain a fitted stress-strain curve;

[0047] S105. Analyzing the formula corresponding to the fitted stress-strain curve to obtain the uniform elongation of the pipeline steel to be tested.

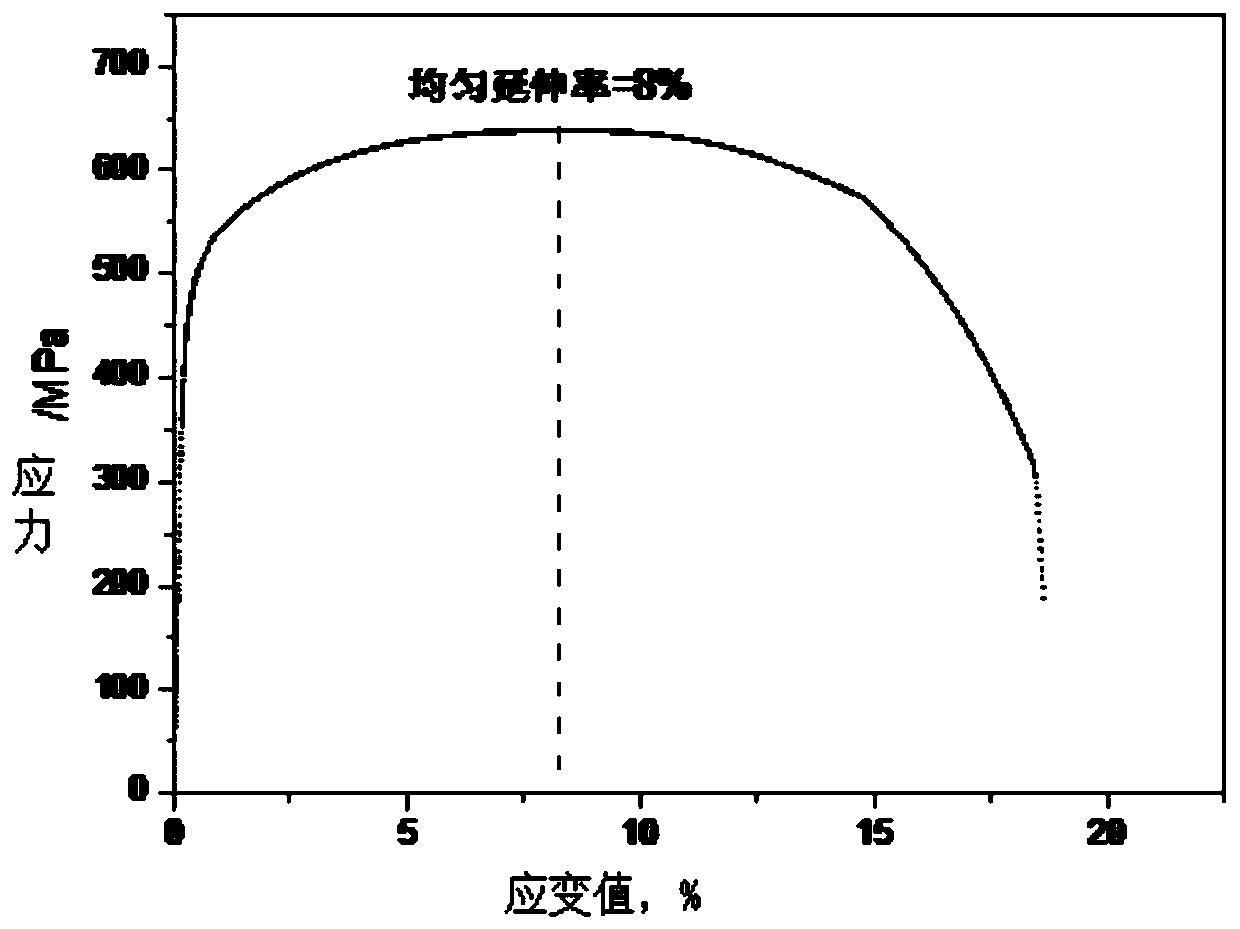

[0048] In the following, taking the measurement of

Embodiment 2

[0067] In this embodiment, a system for measuring the uniform elongation of pipeline steel, see figure 2 , the system includes:

[0068] The first obtaining module is used to obtain the steel plate sample of the pipeline to be tested;

[0069] The first obtaining module is used to perform a tensile test on the pipeline steel plate sample to obtain an engineering stress-strain curve;

[0070] The second acquisition module is used to acquire a set of data points in a preset interval from the engineering stress-strain curve; wherein, the starting point of the preset interval is the data point corresponding to a strain of 0.5%, and the end point is corresponding to the maximum stress value The strain value increases by 1-2% to the data point corresponding to the strain point;

[0071] The second obtaining module is used to fit the set of data points to obtain a fitted stress-strain curve;

[0072] The third obtaining module is configured to analyze the formula corresponding to th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap