Coloring TPU (thermoplastic polyurethane elastomer) foamed beads as well as preparation method and application thereof

A foaming bead and color paste technology, applied in spray evaporation, coating, etc., can solve interfacial migration and volatilization, reduce TPU melt extensional viscosity and melt strength, and affect the cell structure and expansion of foamed materials rate and other issues, to achieve the effect of uniform surface pigment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

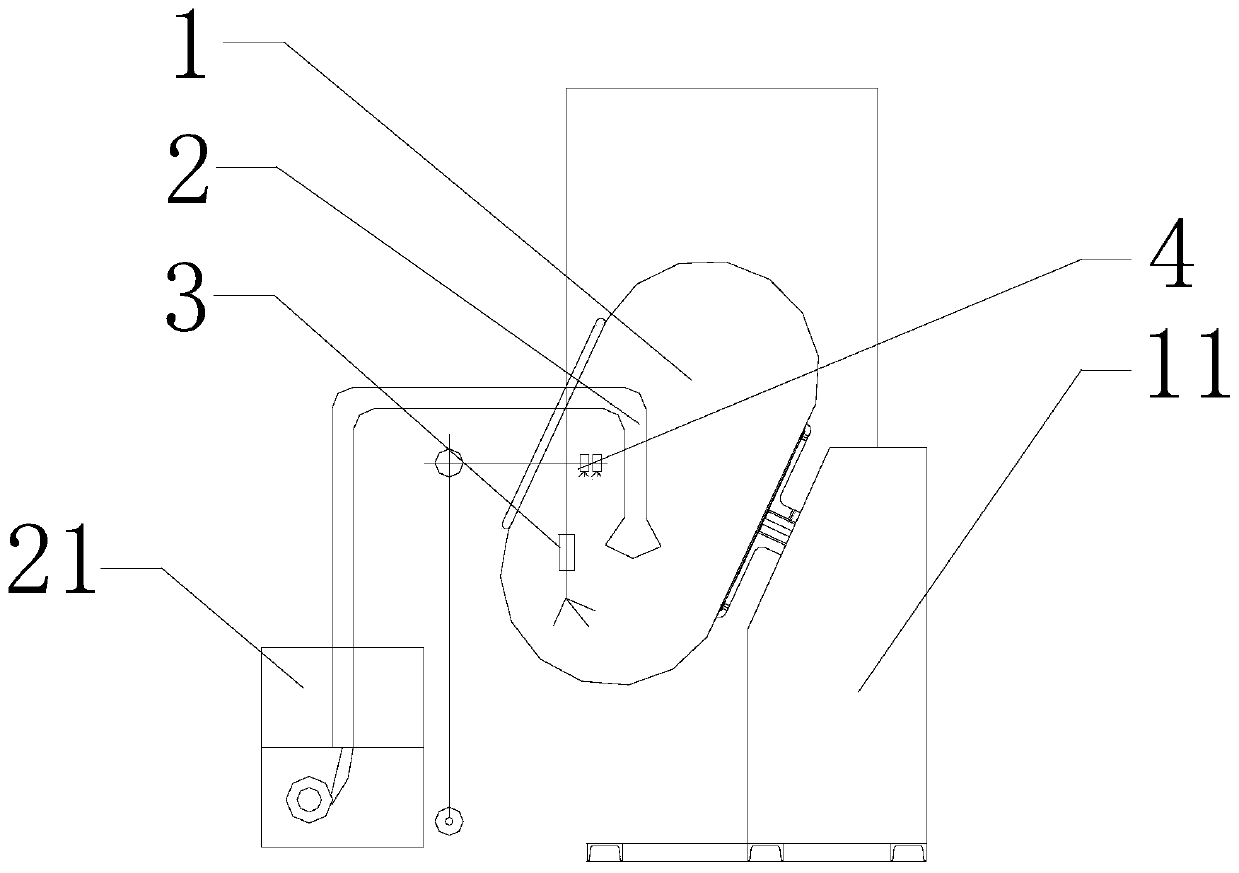

Image

Examples

Embodiment 1

[0067] White TPU foam beads with a specific gravity of 0.11g / cm3 prepared by the gas impregnation method in a kettle.

[0068] 1) First, use the ultrasonic cleaning process to remove the grease and dirt on the surface of the white TPU foam beads, rinse, and dry at 50-100°C. The cleaning liquid is a water-based cleaning liquid containing 10% surfactant 6501, and the ultrasonic Frequency 25KHz, power density 0.35W / cm 2 ;

[0069] 2) The surface of the treated white TPU foam beads is then subjected to low-temperature plasma treatment, the working gas is nitrogen, the working pressure is 100Pa, and the temperature is 80°C;

[0070] 3) the carboxyl type water-based polyurethane spray solution containing black color paste is prepared with a solid content of 10%, which includes:

[0071] a. The amount of carbon black in the black color paste / the solid amount of water-based polyurethane = 1:50;

[0072] b. Select the aqueous antioxidant dispersion containing triethylene glycol

Embodiment 2

[0079] The specific gravity prepared by the gas impregnation method in the kettle is 0.16g / cm 3 White TPU foam beads.

[0080] 1) First use the ultrasonic cleaning process to remove the grease and dirt on the surface of the white TPU foam beads, rinse, and dry at low temperature. The cleaning liquid is a water-based cleaning liquid containing 10% surfactant 6501, and the ultrasonic frequency is 25KHz. Power density 0.35W / cm2;

[0081] 2) The surface of the treated white TPU foam beads is then subjected to low-temperature plasma treatment, the working gas is nitrogen, the working pressure is 100Pa, and the temperature is 80°C;

[0082] 3) preparing the carboxyl-based aqueous polyurethane spray solution containing blue color paste with a solid content of 10%, which includes:

[0083] a. The amount of blue pigment in the blue color paste / the solid amount of water-based polyurethane = 1:5;

[0084] b. Select the aqueous antioxidant dispersion containing triethylene glycol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap