Single-guide-beam downlink type bridge feeding device and bridge feeding method thereof

A beam-feeding, row-type technology, which is applied in the field of single-guide beam downward-type beam-feeding devices, can solve the problems of needing the assistance of large cranes and high-altitude operations, the wear and tear of hoist wire ropes, and rollover accidents during installation and commissioning, so as to reduce the risk of rollover and erection The process is stable and the effect of avoiding wear and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

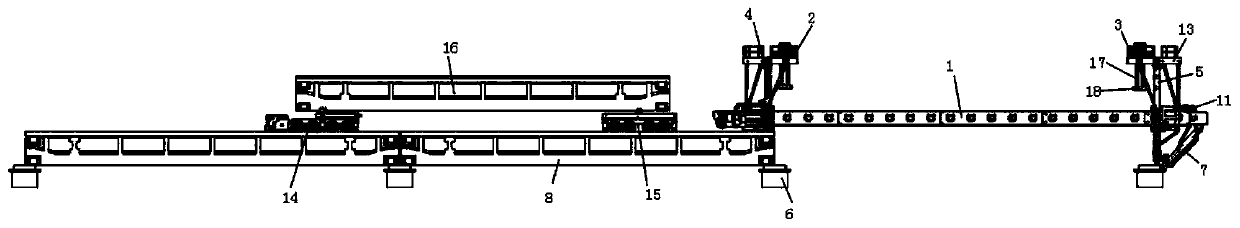

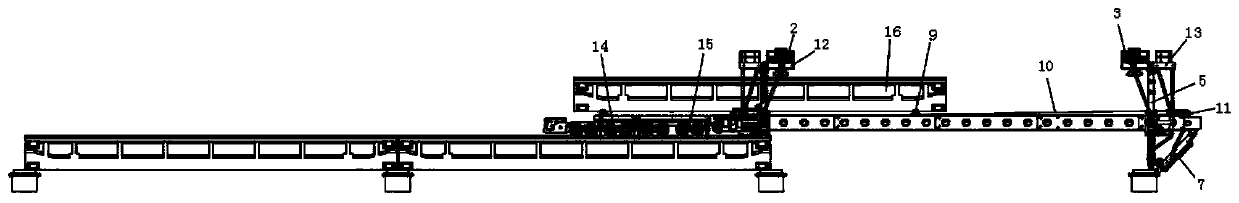

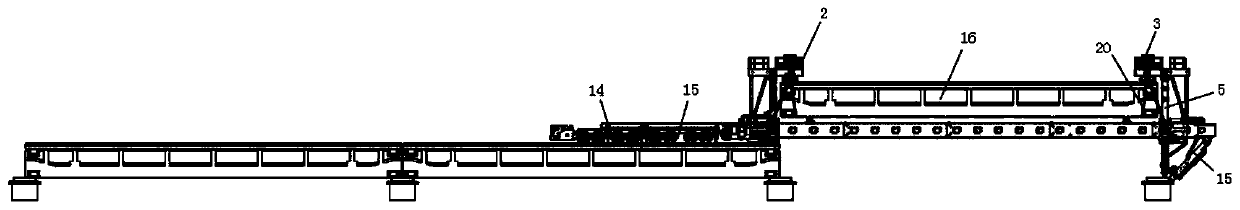

[0028] see Figure 1-6 As shown, a single guide girder descending type beam feeding device includes an active vehicle 14 and a passive vehicle 15 that drag the prefabricated bridge 16 to move along the length direction of the main bridge 8, and are used to move the prefabricated bridge 16 to the upper end of the main beam 1 Carrying trolley 9 and active vehicle 14 and passive vehicle 15 end are provided with docking mechanism 19, wherein, the structure of active vehicle 14 and passive vehicle 15 is identical, and the bottom en

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap