Chip and electronic equipment

A technology of electronic equipment and chips, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of chip junction temperature rise, retention, chip failure, etc., and achieve the effect of improving heat dissipation performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are preferred embodiments of the application. It should be pointed out that for those skilled in the art, without departing from the principle of the application, some improvements and modifications can also be made, and these improvements and modifications are also considered as the present invention. The scope of protection applied for.

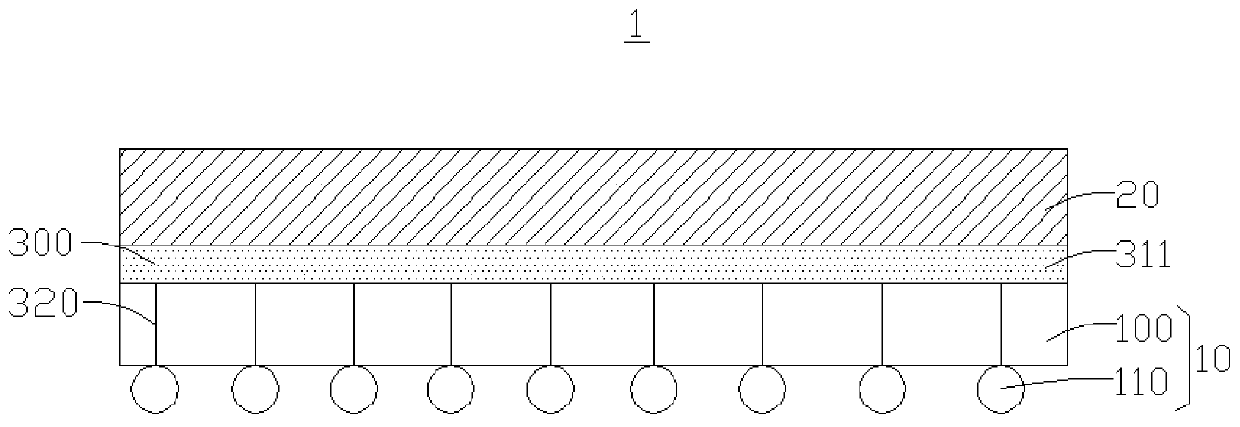

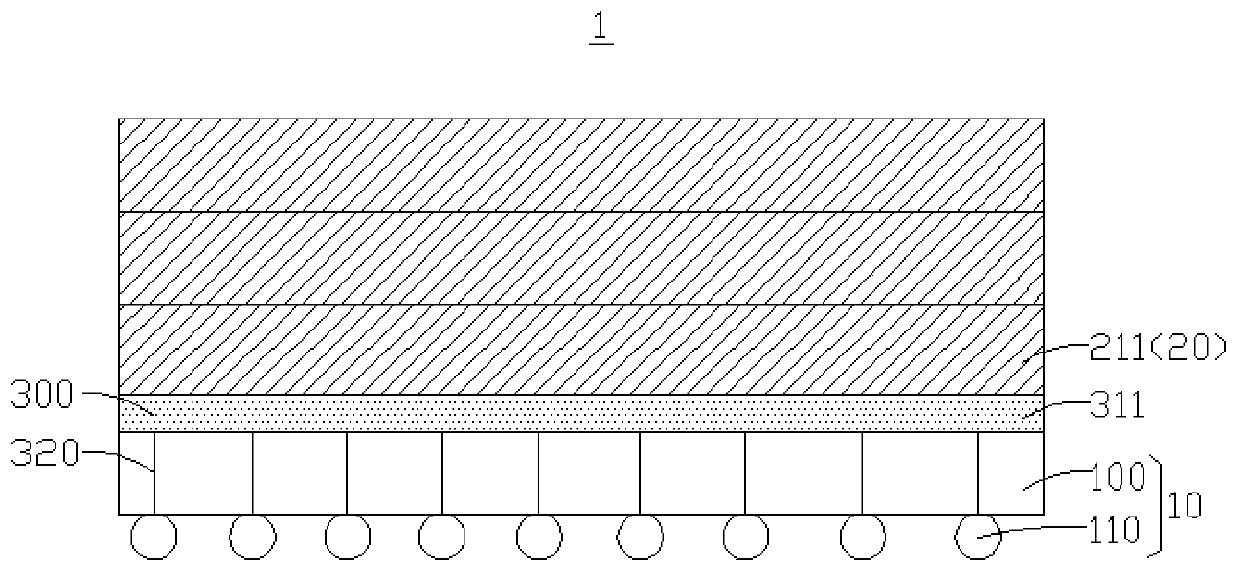

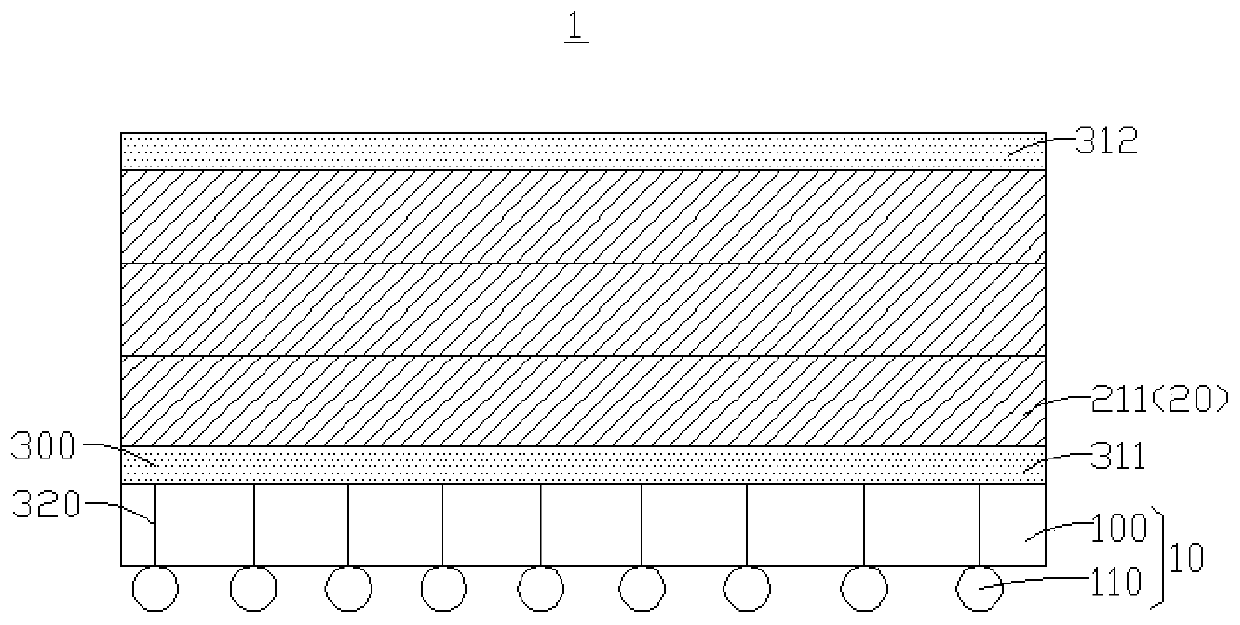

[0047] Please refer to figure 1 . figure 1 It is a schematic structural diagram of the chip according to the first embodiment of the present application. This embodiment provides a chip 1 , the chip 1 includes: a base material 10 , and the base material 10 includes a substrate 100 and a plurality of first solder balls 110 carried on the substrate 100 . The functional module 20, the functional module 20 and the first solder ball 110 are respectively disposed on opposite sides of the substrate 100, and the functional module 20 dissipates heat during operation. The heat conduction device 300, the heat conduction device 300

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap