Heating temperature control method for adjusting charging bucket threshold value based on spice liquid weight

A control method and spice liquid technology, which are applied in the direction of temperature control using electric methods, electrical program control, program control in sequence/logic controllers, etc., can solve the problem that the temperature cannot be controlled within a good range and the temperature of the heating device Problems such as overshooting and inability to control the steam opening, etc., to achieve significant control effects, weakened temperature fluctuations, and avoid capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

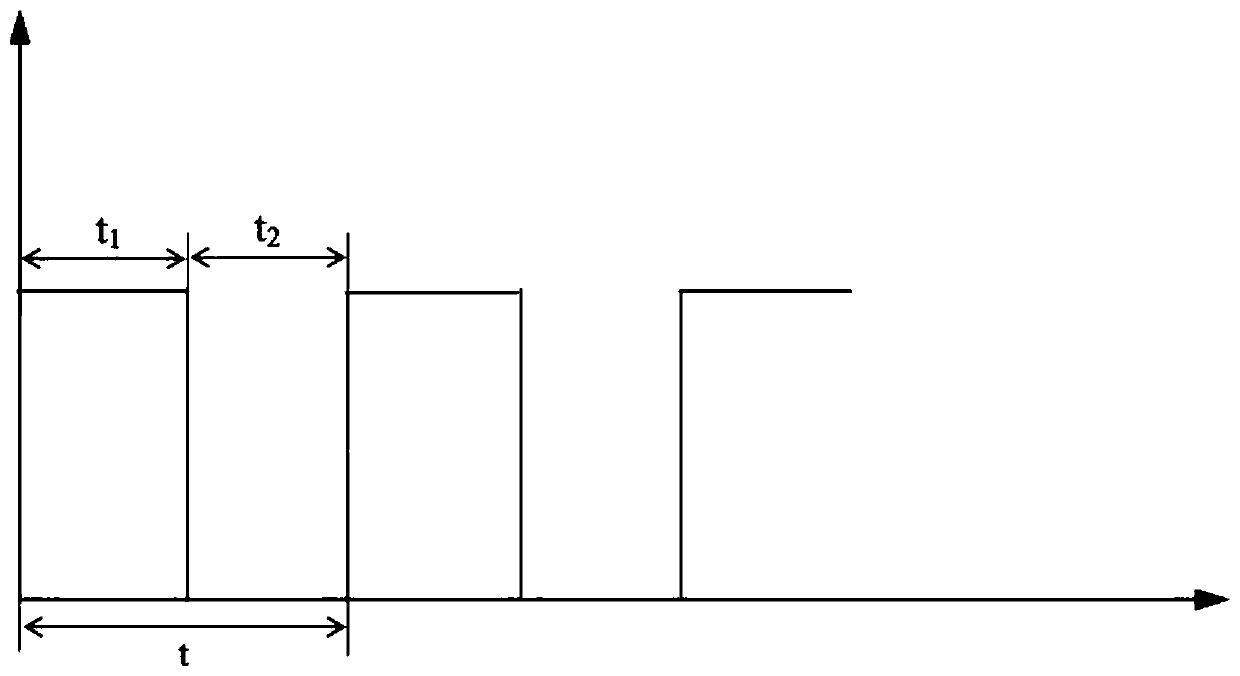

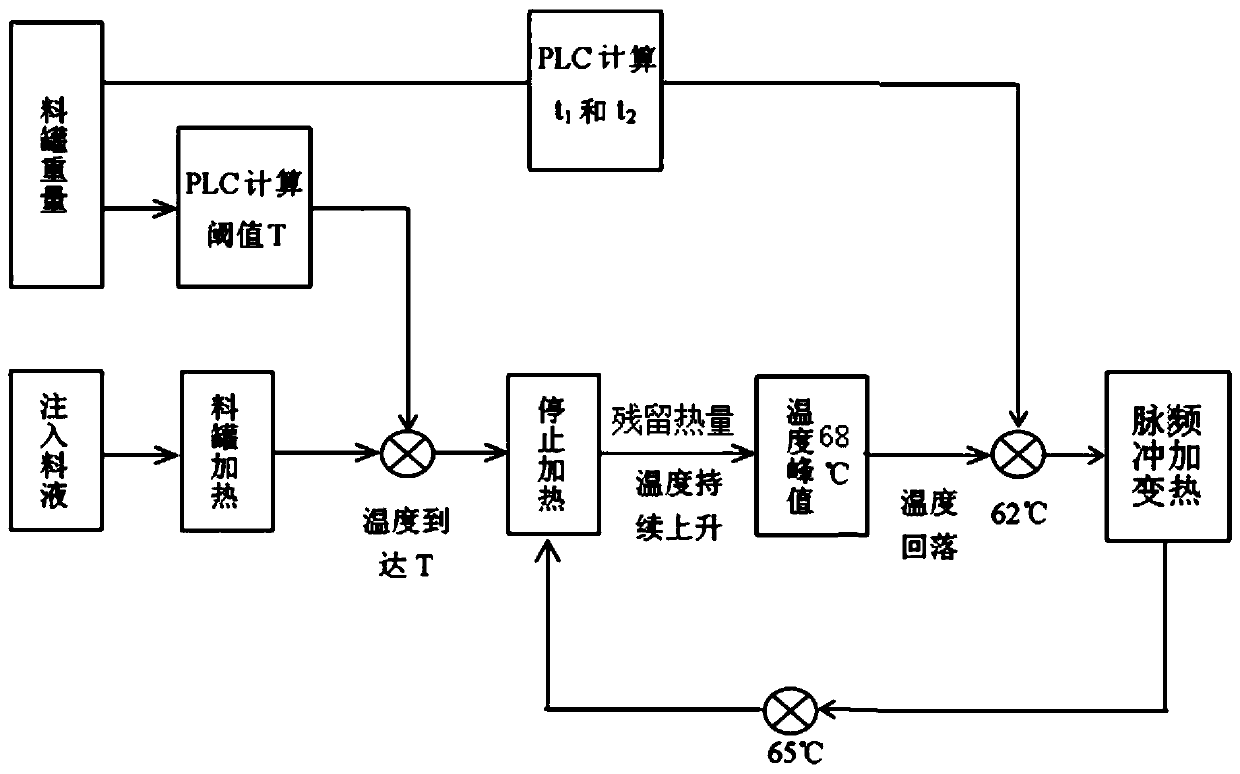

[0021] A: Add 300Kg of spice liquid to the material tank for use. Set the basic parameters and formulate the calculation threshold in the PLC controller; set the temperature-quality ratio coefficient K according to the equipment situation and process requirements 1 The value is 750, the valve opening time base value K 2 Is 5, the time-quality ratio coefficient K 3 Is 25, and the rectangular wave period t is 30s;

[0022] B: First click the control button "tank heating" on the material tank, the material tank enters the first heating stage, and the steam valve remains open;

[0023] C: Steam into the middle layer of the material tank to heat the perfume liquid to 62~65℃. At this time, the residual heat in the middle layer of the material tank is basically fixed. The mass of the perfume liquid 300Kg is collected through the PLC controller program and substituted into the calculation threshold The formula T=65-750 / M, where M is the quality of the material liquid, and t

Example Embodiment

[0027] Example 2

[0028] A: Add 450Kg of spice liquid to the material tank for use, set the basic parameters and formulate the calculation threshold value in the PLC controller; set the temperature mass ratio coefficient K according to the equipment situation and process requirements 1 The value is 750, the valve opening time base value K 2 Is 5, the time-quality ratio coefficient K 3 Is 25, and the rectangular wave period t is 30s;

[0029] B: First click the control button "tank heating" on the material tank, the material tank enters the first heating stage, and the steam valve remains open;

[0030] C: Steam into the middle layer of the material tank to heat the perfume liquid to 62~65℃. At this time, the residual heat in the middle layer of the material tank is basically fixed. The mass of the perfume liquid 450Kg is collected through the PLC controller program and substituted into the calculation threshold. The formula T=65-750 / M, where M is the quality of the material liquid, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap