Processing method for inhibiting recrystallization of aluminum lithium alloy

An aluminum-lithium alloy and processing method technology, applied in the field of aluminum-lithium alloy processing, can solve the problems that recovery annealing cannot achieve the desired effect, does not have universality, and the effect is unstable, so as to inhibit the occurrence of final solid solution recrystallization and reduce the shape of the alloy. Nucleation point, the effect of eliminating the local strain area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The aluminum-lithium alloy ingot is prepared by vacuum melting and casting. The chemical composition of the prepared aluminum-lithium alloy is Cu: 2.7wt%, Li: 1.8wt%, Mg: 0.4wt%, Mn: 0.4wt%, Zn: 0.6 wt%, Zr: 0.1wt%, the balance is aluminum;

[0036] (2) Homogenize the ingot at 520°C for 75 hours;

[0037] (3), the homogenized ingot is preheated at 450 ° C, kept for 20 minutes, and then rolled into a plate;

[0038] (4) The aluminum-lithium alloy plate after billeting is subjected to solution treatment at 540° C. for 1 hour, and then quenched with cold water at 25° C.;

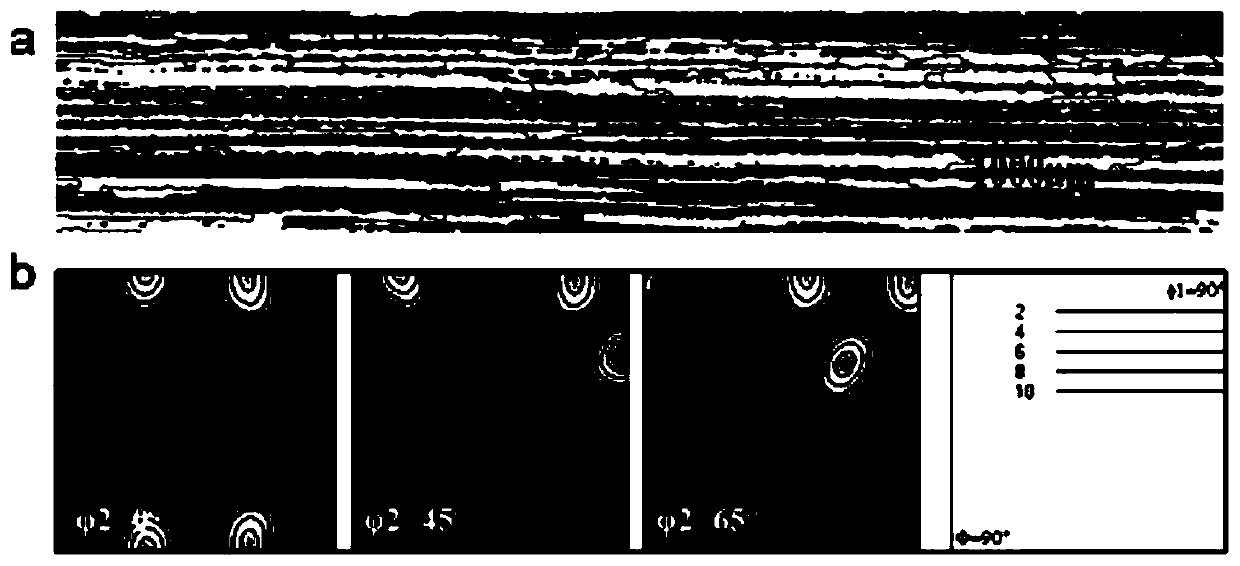

[0039] (5) Rolling the quenched aluminum-lithium alloy sheet 6 times at 250° C., the reduction rate of each pass is 16%, the total reduction rate is 65%, and the rolling speed is 6m / min;

[0040] (6) Perform final solid solution on the aluminum-lithium alloy plate after multi-pass temperature-controlled hot rolling, and perform solution treatment at 540° C. for 1 hour;

[0041] (7) pre-stretching t

Embodiment 2

[0046] A processing method for suppressing the subsequent recrystallization of an aluminum-lithium alloy is carried out as follows:

[0047] (1), using vacuum melting and casting method to prepare aluminum-lithium alloy ingot, the chemical composition of the prepared aluminum-lithium alloy is Cu: 2.8wt%, Li: 1.9wt%, Mg: 0.3wt%,; Mn: 0.5wt%, Zn: 0.7wt%, Zr: 0.08wt%, Si: 0.05wt%, Fe: 0.07wt%, the balance is aluminum;

[0048] (2) Homogenize the ingot at 530°C for 80 hours;

[0049] (3), the homogenized ingot is preheated at 460 ° C, kept for 40 minutes, and then rolled into a plate;

[0050] (4) Carry out solid solution treatment at 510° C. for 2 hours to the aluminum-lithium alloy plate after billeting, and then quench with cold water at 25° C.;

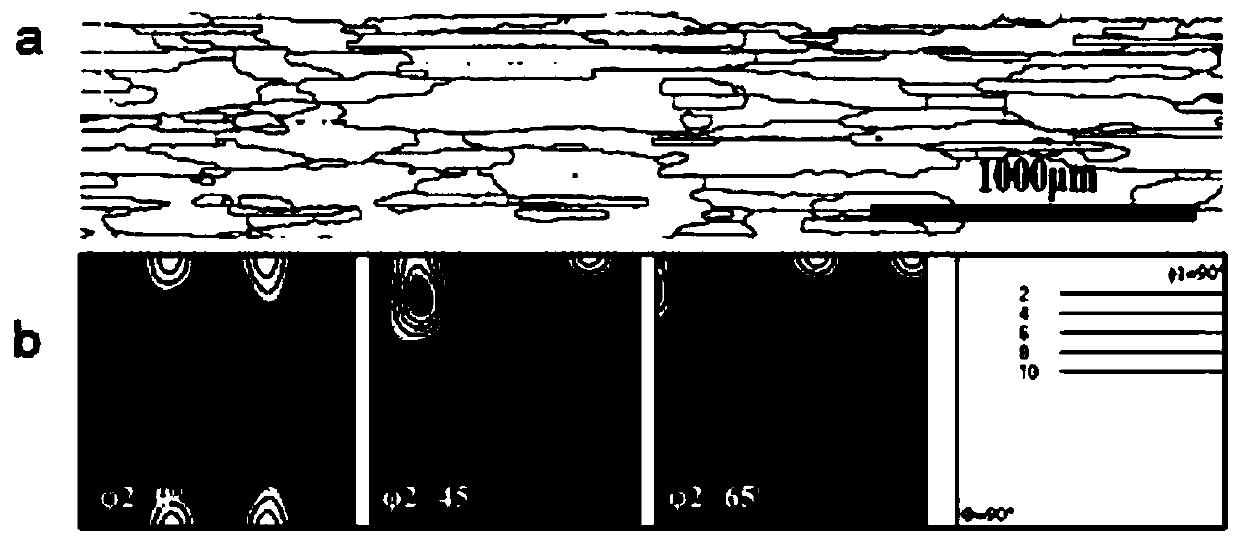

[0051] (5) Rolling the quenched aluminum-lithium alloy plate 5 times at 150° C., the reduction rate of each pass is 15%, the total reduction rate is 55%, and the rolling rate is 4m / min;

[0052] (6) Perform final solid solution on t

Embodiment 3

[0058] A processing method for suppressing the subsequent recrystallization of an aluminum-lithium alloy is carried out as follows:

[0059] (1), using the vacuum casting method to prepare aluminum-lithium alloy ingots, the chemical composition of the prepared aluminum-lithium alloy is Cu: 2.7wt%; Li: 1.7wt%; Mg: 0.5wt%; Mn: 0.3wt%; Zn: 0.5 wt%; Zr: 0.12wt%, Si: 0.03wt%, Fe: 0.04wt%, the balance is aluminum;

[0060] (2) Homogenize the ingot at 510°C for 70 hours;

[0061] (3), the homogenized ingot is preheated at 420 ° C, kept for 35 minutes, and then rolled into a plate;

[0062] (4) The aluminum-lithium alloy plate after billeting is subjected to solution treatment at 550° C. for 0.5 h, and then quenched in cold water at 25° C.;

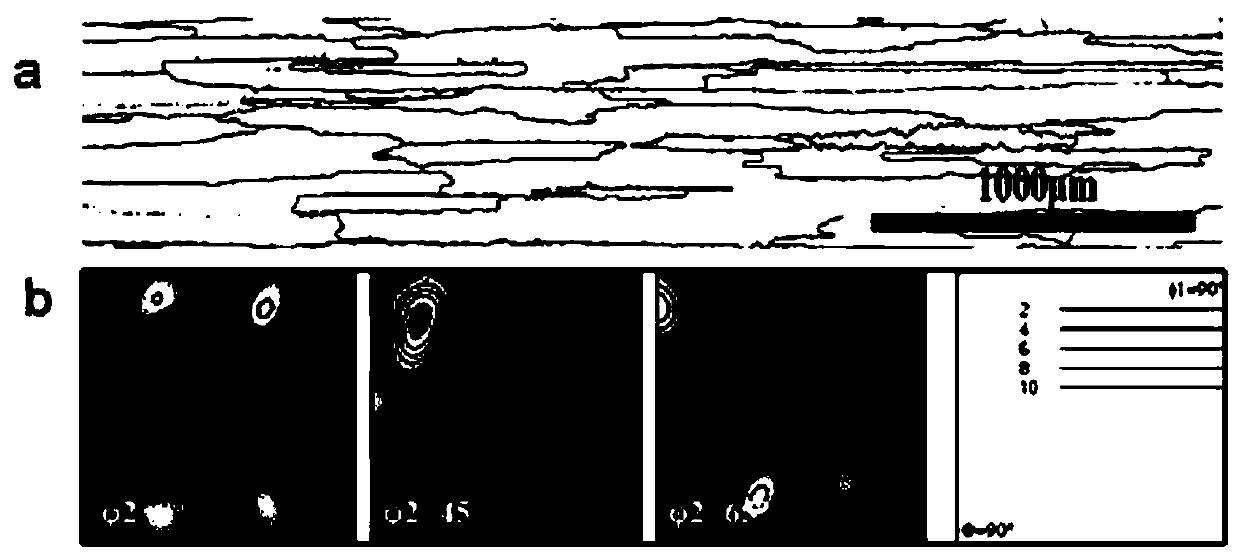

[0063] (5) Rolling the quenched aluminum-lithium alloy sheet 8 times at 350° C., the reduction rate of each pass is 20%, the total reduction rate is 83%, and the rolling rate is 8m / min;

[0064] (6) Perform final solid solution on the aluminum-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap