Highly-ionized energy element sampling system of inductively coupled plasma emission spectrometer

A plasma and inductive coupling technology, which is applied in the direction of material analysis, instruments, and scientific instruments by optical means, can solve the problems of low detection sensitivity, achieve low detection sensitivity, increase the concentration of the element to be tested, and improve the effective injection. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

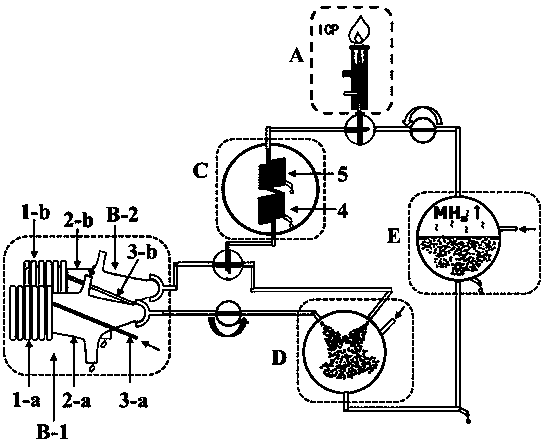

[0013] Such as figure 1 As shown, the high ionization energy element sampling system of the inductively coupled plasma emission spectrometer includes the inductively coupled plasma emission spectrometer A, and the system also includes the ultrasonic atomization device IB-1, the ultrasonic atomization device IIB-2, and the solvent removal device C , hydrogenation reaction device D and gas-liquid separation device E; ultrasonic atomization device IB-1 and ultrasonic atomization device IIB-2 both include ultrasonic generators 1-a, 1-b and atomization chambers 2-a, 2-b, Among them, the ultrasonic generator 1-a, 1-b is connected with the spray chamber 2-a, 2-b, and the spray chamber 2-a, 2-b is guided by the spray chamber main body and the sample injection penetrating into the spray chamber main body. tube 3-a, 3-b; the desolvation device C includes a heating tube 4 and a condenser tube 5 connected from bottom to top through a glass ball grinding port; The chemical chamber 2-a is con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap