Garbage cleaning ship

A garbage cleaning and cleaning area technology, applied in the field of cleaning ships, can solve the problems of unsatisfactory, floating garbage that cannot be salvaged manually, and achieve the effects of reducing working time, prolonging effective working time, and facilitating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

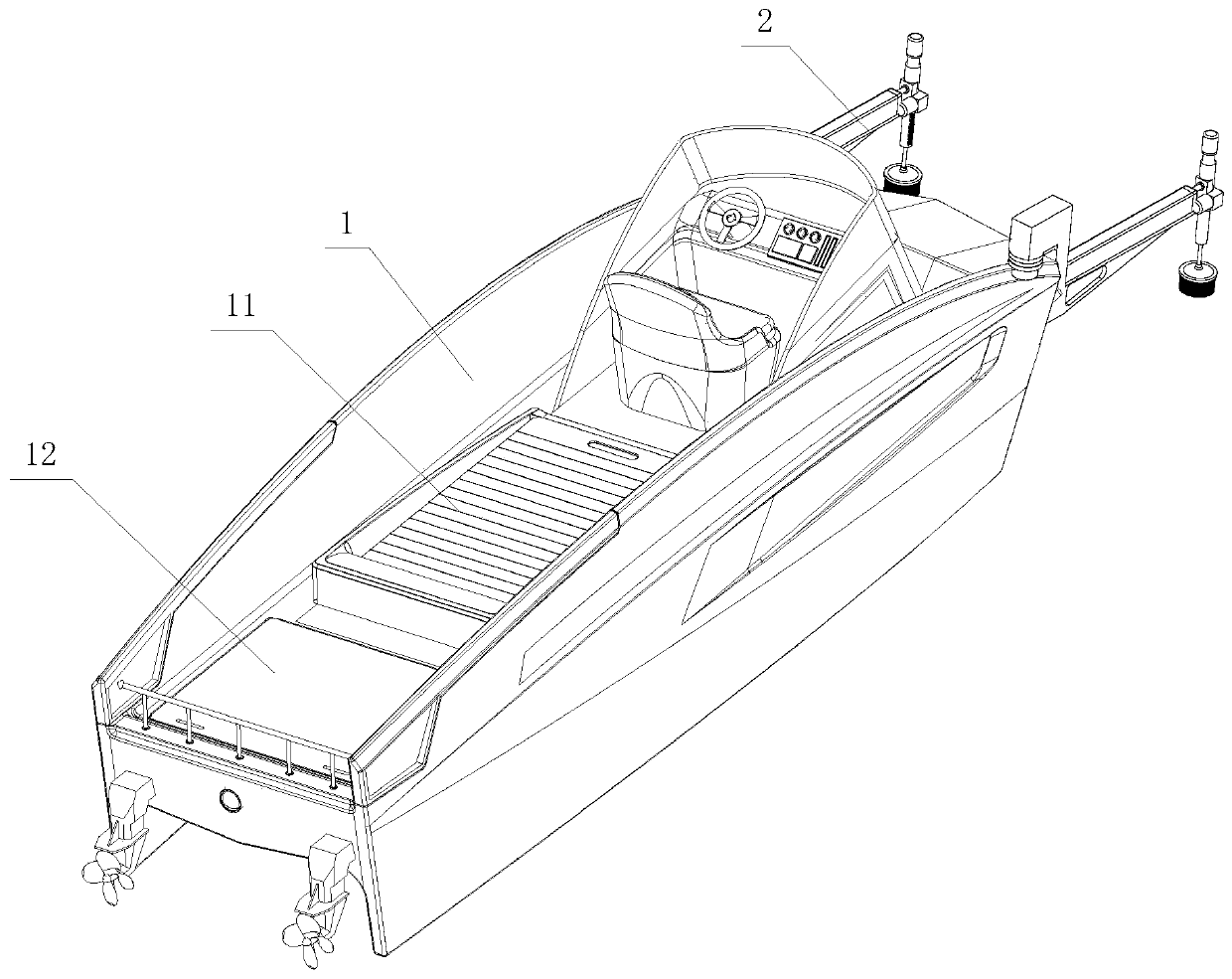

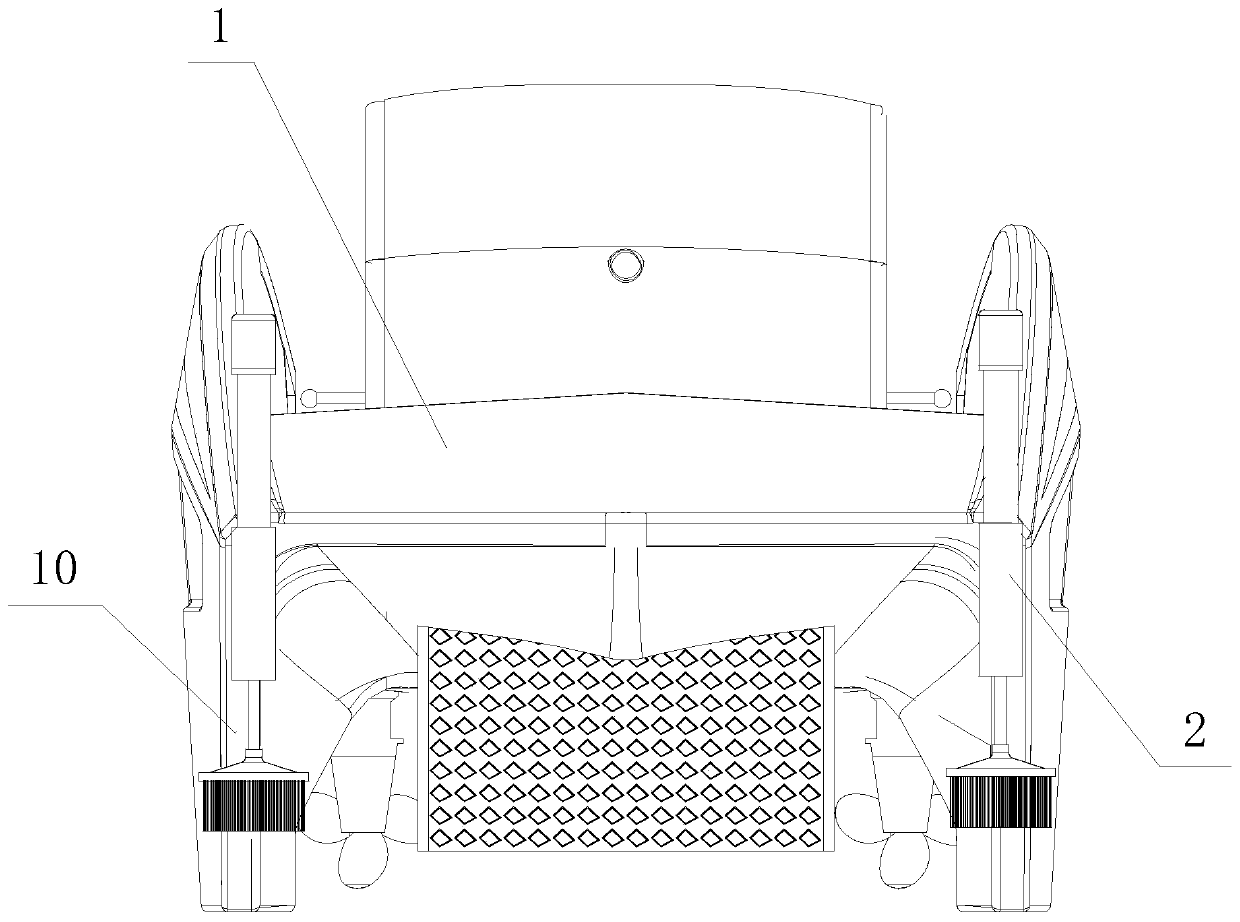

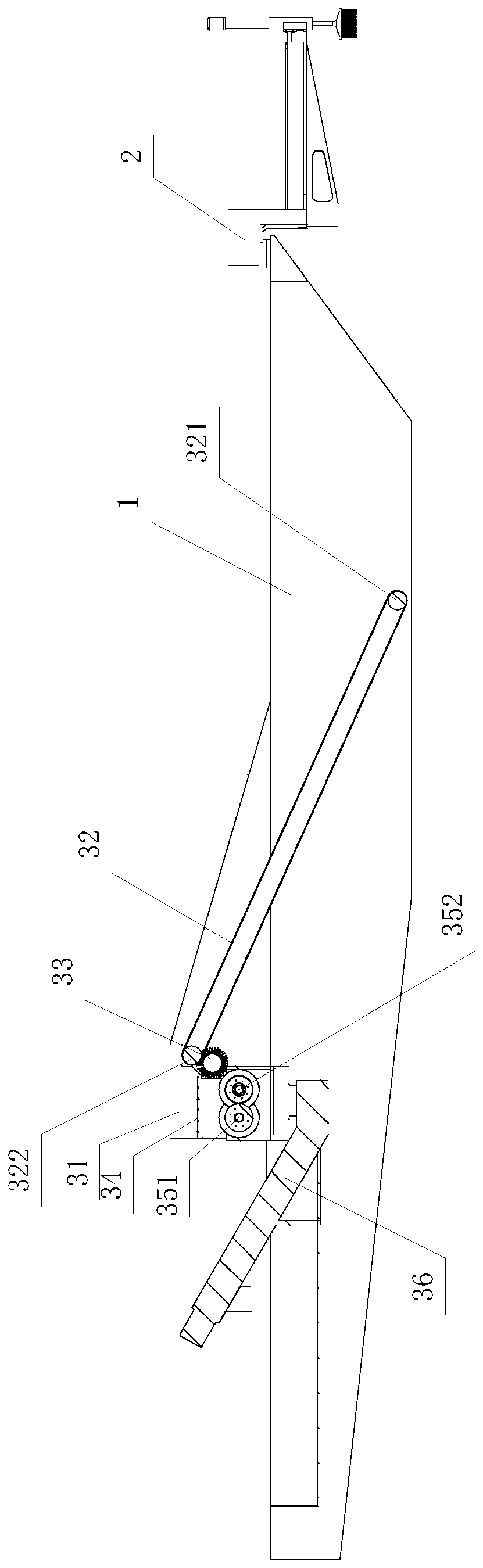

[0027] refer to Figure 1 to Figure 8 , the present invention provides a kind of rubbish clearing ship, is used for clearing up floating rubbish on the water surface, and it comprises catamaran hull 1, and catamaran hull structure refers to figure 1 and figure 2 , floating bodies 10 are arranged on both sides of the bottom of the catamaran hull, the floating bodies support the entire hull, a cleaning area is formed between the two floating bodies, and the cleaning area runs through front and back. During driving, a part of water can pass through the cleaning area, and in When on the water surface, a part of the upper end of the cleaning area is located above the water surface to allow floating objects on the water surface to pass through. Specifically, there is a gap between the upper surface of the cleaning area and the water surface, and the gap is us

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap