Novel organic material and application thereof in devices

An organic material and a new type of technology, applied in the field of organic electroluminescent display, can solve the problems of low electron mobility, serious power consumption, and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

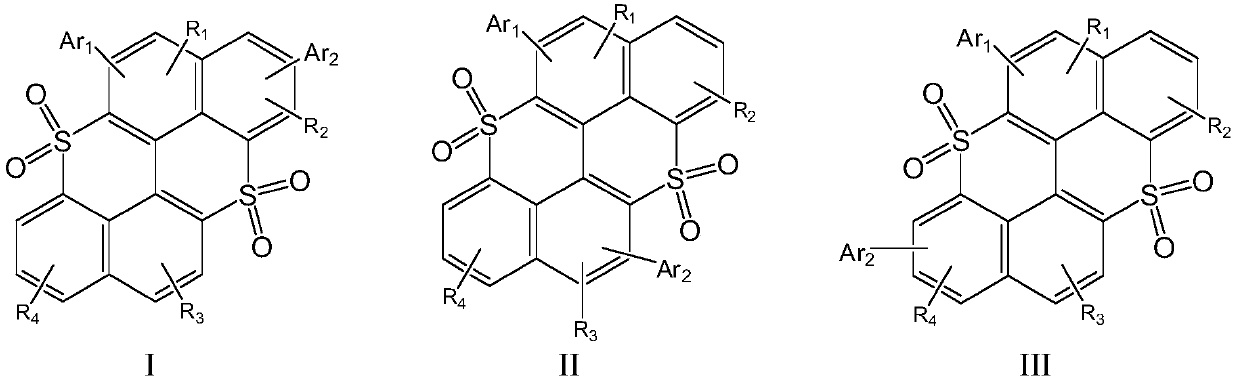

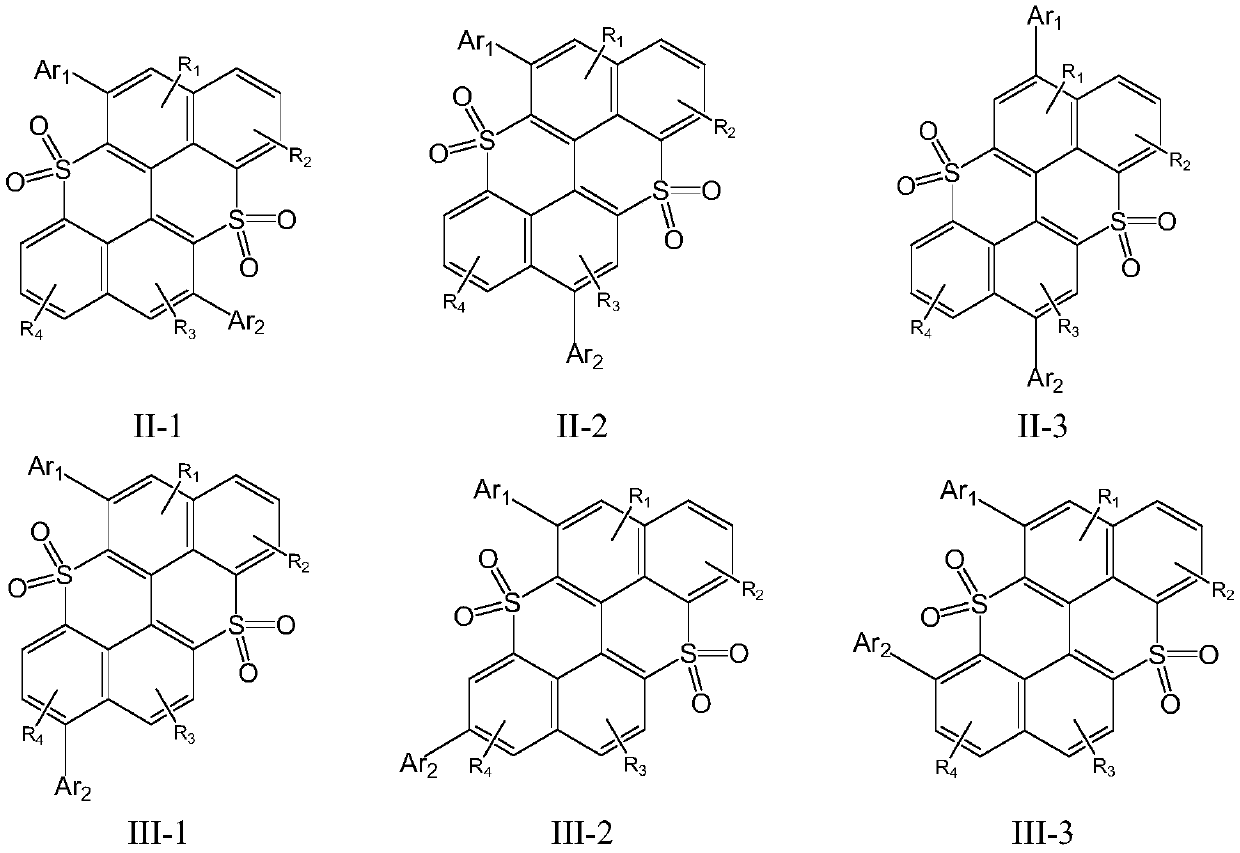

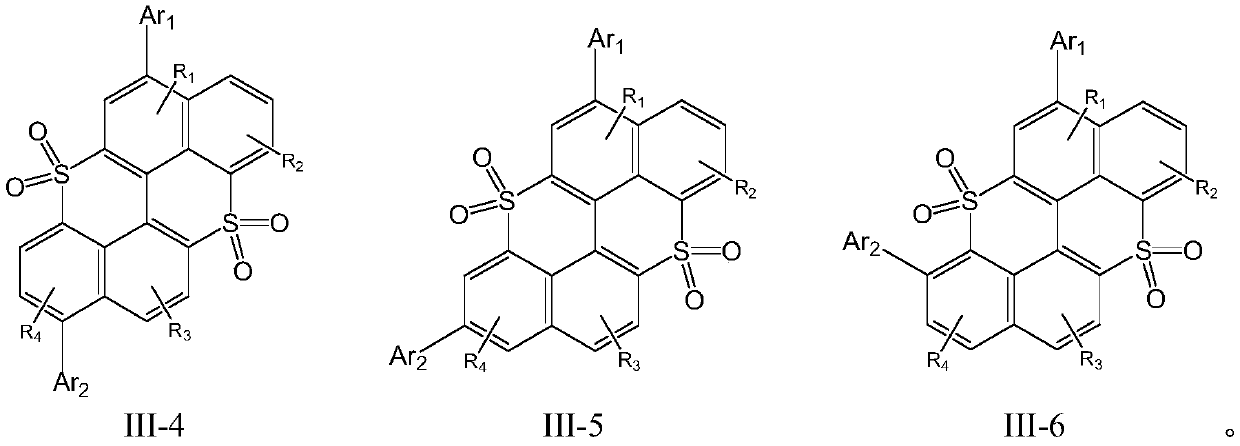

Method used

Image

Examples

Embodiment 1

[0073] Synthesis of (Compound II-1-1)

[0074] The synthetic route is as follows:

[0075]

[0076] Synthesis of Compound II-1-1

[0077] A 1-liter three-neck flask equipped with a magnetic stirrer. After nitrogen replacement, 40.07 g (0.378 mol) of sodium carbonate, 25.62 g (purity 99%, 0.21 mol) of phenylboronic acid and 100 ml of toluene were added in sequence. After nitrogen replacement again, 0.5 g of Pd132 was added in sequence. After the addition, the temperature was raised to 80°C. Start to drop a solution consisting of 53.6 g of compound P1 (purity 99%, 0.1 mol) and 100 ml of toluene, and control the temperature at 75-90°C. Cool down to room temperature, add 100ml of deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF to obtain 42.93g of a light yellow solid with a purity of 99% and a yield of 81%.

[0078] Product MS (m / e): 530; Elemental analysis (C 32 h 18 o 4 S 2 ): theoretical value C: 72.43%; H

Embodiment 2

[0080] Synthesis of (Compound II-1-6)

[0081] The synthetic route is as follows:

[0082]

[0083] Synthesis of compound II-1-6

[0084] A 1-liter three-neck flask equipped with a magnetic stirrer. After nitrogen replacement, 40.28 g (0.38 mol) of sodium carbonate, 41.58 g (purity 99%, 0.21 mol) of 4-biphenylboronic acid and 100 ml of toluene were added in sequence. After nitrogen replacement again, 0.5 g of Pd132 was added in sequence. After the addition, the temperature was raised to 80°C. Start to drop a solution consisting of 53.6 g of compound P1 (purity 99%, 0.1 mol) and 100 ml of toluene, and control the temperature at 75-90°C. Cool down to room temperature, add 100ml of deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF to obtain 54.56g of a light yellow solid with a purity of 99% and a yield of 80%.

[0085] Product MS (m / e): 682; Elemental analysis (C 44 h 26 o 4 S 2 ): theoretical value C: 77.40%

Embodiment 3

[0087] Synthesis of (Compound II-1-11)

[0088] The synthetic route is as follows:

[0089]

[0090] Synthesis of compound II-1-11

[0091] A 1-liter three-neck flask equipped with a magnetic stirrer. After nitrogen replacement, 40.07 g (0.378 mol) of sodium carbonate, 42.84 g (purity 99%, 0.21 mol) of (4-cyclohexylphenyl) boric acid and 100 ml of toluene were added in sequence. After nitrogen replacement again, 0.5g of Pd132 was added in sequence. After the addition, the temperature was raised to 80°C. Start to drop a solution consisting of 53.6 g of compound P1 (purity 99%, 0.1 mol) and 100 ml of toluene, and control the temperature at 75-90°C. Cool down to room temperature, add 100ml of deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF to obtain 55.52g of a light yellow solid with a purity of 99% and a yield of 80%.

[0092] Product MS (m / e): 694; Elemental Analysis (C 44 h 38 o 4 S 2 ): theoretical valu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap