Bipolar copolymer blue phosphorescence main material, preparation method thereof and organic electroluminescent device

A bipolar copolymer and phosphorescent host technology, which can be used in luminescent materials, electro-solid devices, semiconductor devices, etc., can solve the problems of poor thermal stability and low luminous efficiency, and achieve excellent film-forming performance and high electroluminescence efficiency. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

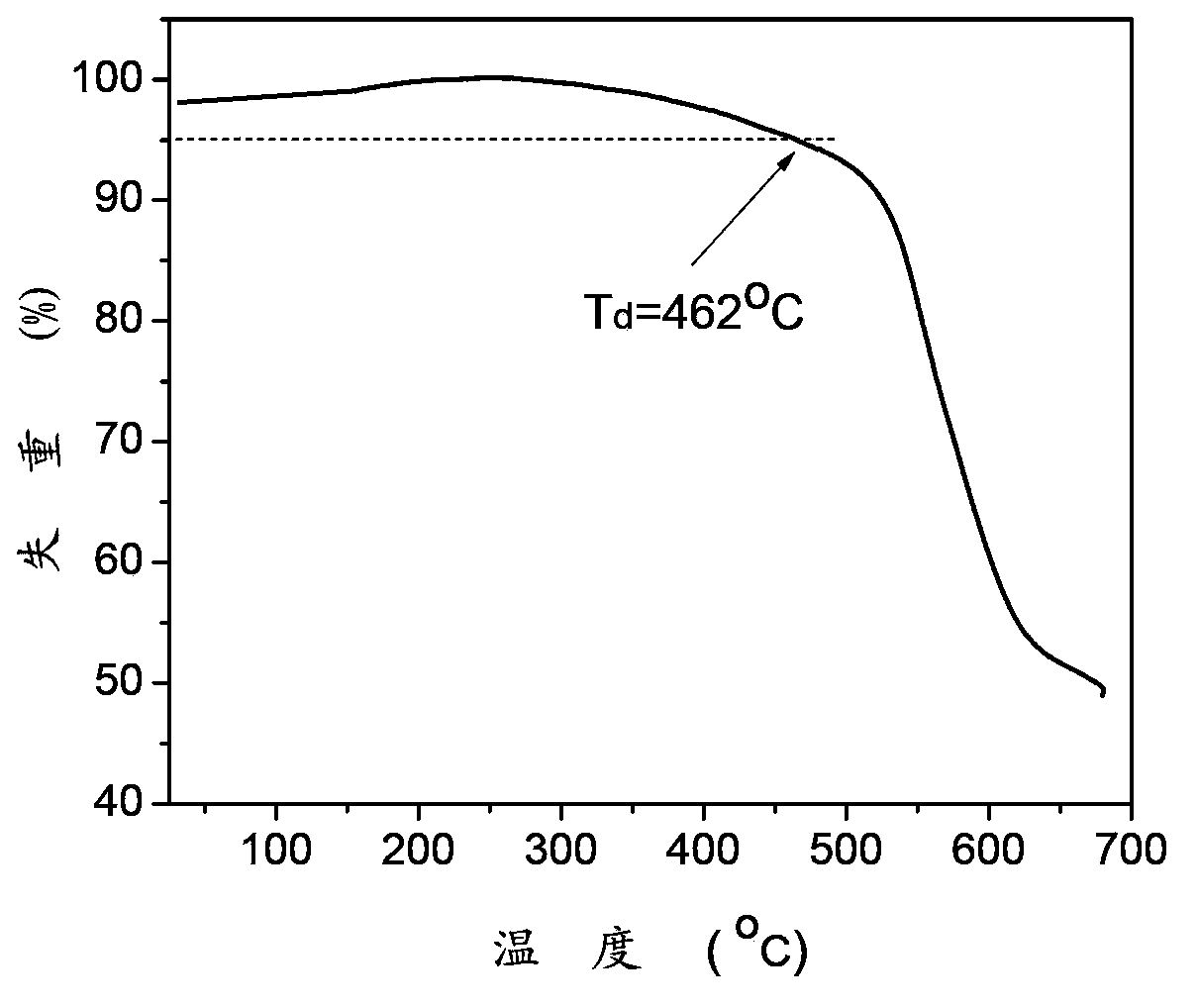

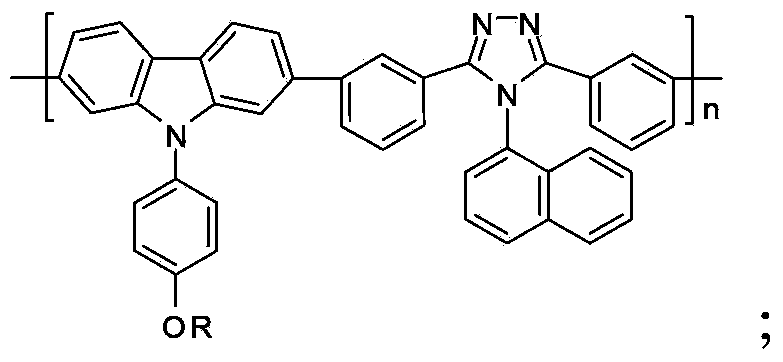

[0032] The bipolar copolymer blue-light phosphorescent host material of this embodiment, that is, poly{N-(4-n-hexyloxyphenyl)-2,7-diylcarbazole-co-3,5-di(3-yl -Phenyl)-4-naphthyl-4H-1,2,4-triazole} (P1) (where R is n-hexyl, n=39), its structural formula is as follows:

[0033]

[0034] The preparation steps of above-mentioned polymer are as follows:

[0035] The reaction formula is as follows:

[0036]

[0037] Under argon protection, N-(4-n-hexaneoxyphenyl)-2,7-dipinacol borate carbazole (119mg, 0.2mmol), 3,5-bis(3-bromobenzene Base)-4-naphthyl-4H-1,2,4-triazole (101mg, 0.2mmol) was added to a flask containing 10ml of toluene solvent, and after fully dissolving, potassium carbonate (2mL, 2mol / L) solution was added to In the flask, the oxygen was vacuumed and filled with argon, and then bistriphenylphosphine palladium dichloride (5.6mg, 0.008mmol) was added; the flask was heated to 100°C for Suzuki coupling reaction for 48h. Subsequently, the polymerization reaction wa

Embodiment 2

[0041] The bipolar copolymer blue-light phosphorescent host material of this embodiment, that is, poly{N-(4-methoxyphenyl)-2,7-diylcarbazole-co-3,5-bis(3-yl- Phenyl)-4-naphthyl-4H-1,2,4-triazole} (where R is methyl, n=98), its structural formula is as follows:

[0042]

[0043] The preparation steps of above-mentioned polymer are as follows:

[0044] The reaction formula is as follows:

[0045]

[0046]Under the protection of a mixed gas of nitrogen and argon, N-(4-methoxyphenyl)-2,7-dipinacol borate carbazole (130mg, 0.3mmol), 3,5-bis(3- Bromophenyl)-4-naphthyl-4H-1,2,4-triazole (152mg, 0.3mmol) and 15mL tetrahydrofuran were added to a 50mL two-necked bottle, and after fully dissolving, a mixture of nitrogen and argon was introduced to exhaust After about 20 minutes in the air, tetrakistriphenylphosphine palladium (4mg, 0.003mmol) was added into it, and after fully dissolved, sodium bicarbonate (3mL, 2mol / L) solution was added. Then, the mixed gas of nitrogen and argo

Embodiment 3

[0049] The bipolar copolymer blue-light phosphorescent host material of this embodiment, that is, poly{N-(4-n-eicosyloxyphenyl)-2,7-diylcarbazole-co-3,5-bis(3 -yl-phenyl)-4-naphthyl-4H-1,2,4-triazole} (where R is n-eicosyl, n=83), its structural formula is as follows:

[0050]

[0051] The preparation steps of above-mentioned polymer are as follows:

[0052] The reaction formula is as follows:

[0053]

[0054] Under nitrogen protection, N-(4-n-eicosyloxyphenyl)-2,7-dipinacol borate carbazole (238mg, 0.3mmol), 3,5-bis(3-bromobenzene base)-4-phenyl-4H-1,2,4-triazole (167mg, 0.33mmol), palladium acetate (3.5mg, 0.015mmol) and tris(o-methoxyphenyl)phosphine (21mg, 0.06mmol ) into a flask containing 12mL of N,N-dimethylformamide, fully dissolved and then adding potassium carbonate (3mL, 2mol / L) solution, and then blowing nitrogen into the flask and exhausting the air for about 30min; the flask was heated The Suzuki coupling reaction was performed at 130°C for 12h. Subsequ

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap