High-performance water-based acrylic coating and preparation method thereof

A water-based acrylic, high-performance technology, applied in coatings and other directions, can solve the problems of slow rise in hardness and slow surface drying, and achieve the effect of improving drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] High-performance water-based acrylic coatings, including the following raw materials:

[0038] Water-based acrylic resin, dispersant A, amine neutralizer, defoamer, leveling agent, wetting agent, film-forming aid, anti-settling agent, pigment and filler, thickener, distilled water, silica sol, dispersant B,

[0039] Among them, the water-based acrylic resin core-shell self-crosslinking acrylic water-based emulsion, the model is Wanhua 0613, the glass transition temperature is 25-27 °C, and the solid content is 45%;

[0040] Dispersant A is a high molecular block polymer, the model is BYK190;

[0041] The amine neutralizing agent is a polymer without metal ions, and the present embodiment selects dimethylethanolamine neutralizing agent;

[0042] The defoamer is an acetylenic glycol-based high polymer defoamer, the model is BYK012;

[0043] The leveling agent is a polyether modified silicone leveling agent, the model is BYK347;

[0044] The wetting agent is alkyl polyoxye

Embodiment 2、3

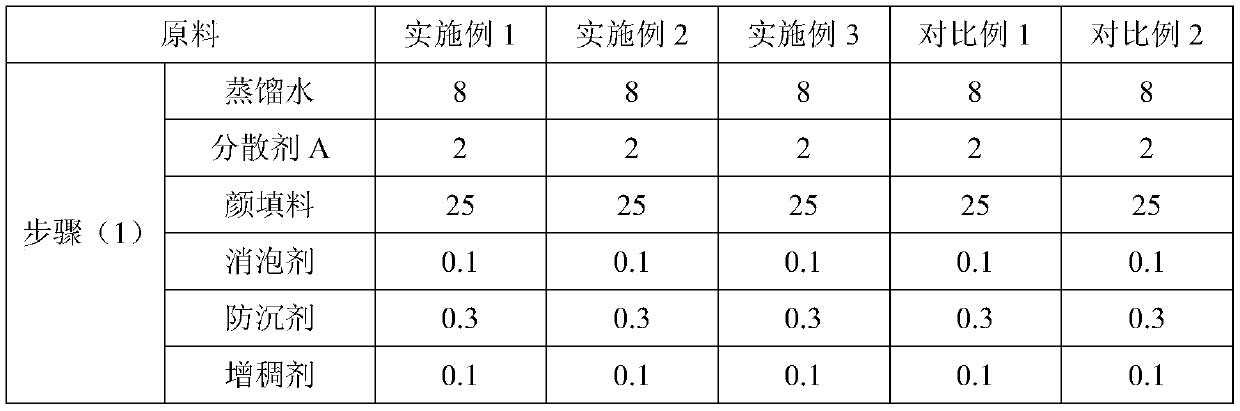

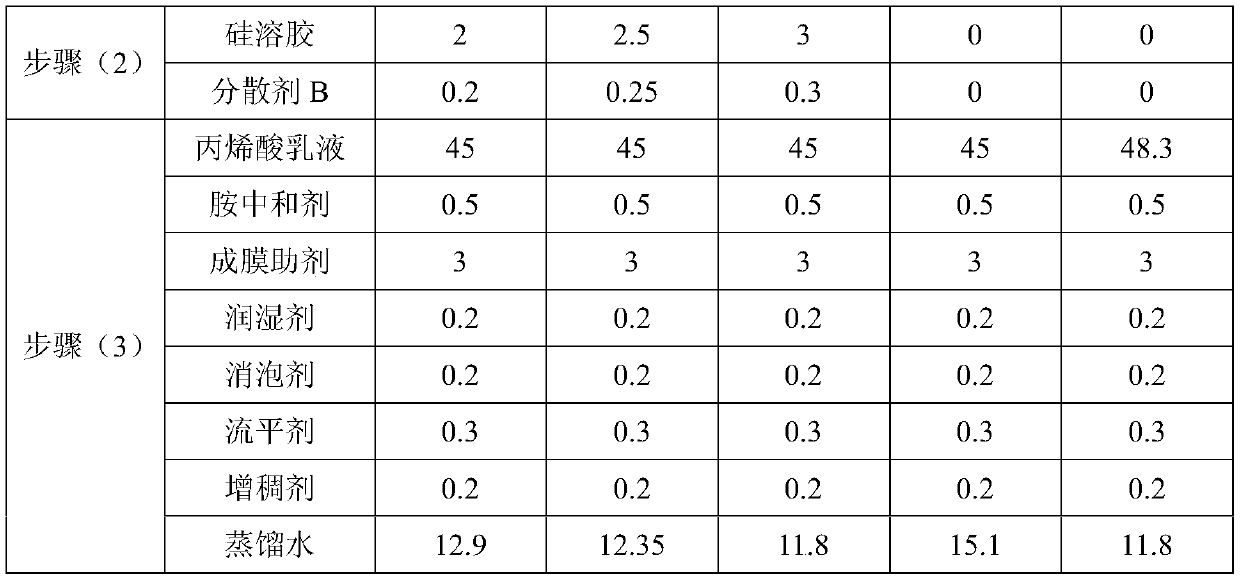

[0057] As shown in Table 1, the difference between Examples 2 and 3 and Example 1 is that the parts by weight of each raw material are different, but the preparation method is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap