Carbon fiber air filtration sterilizer

A sterilization, air filtration technology, applied in the direction of air quality improvement, air conditioning system, mechanical equipment, etc., can solve the problems of reducing the working efficiency of air purifiers, unable to achieve air purification, sterilization and disinfection, poor disinfection and sterilization effect, etc. Simple structure, improved filtering effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

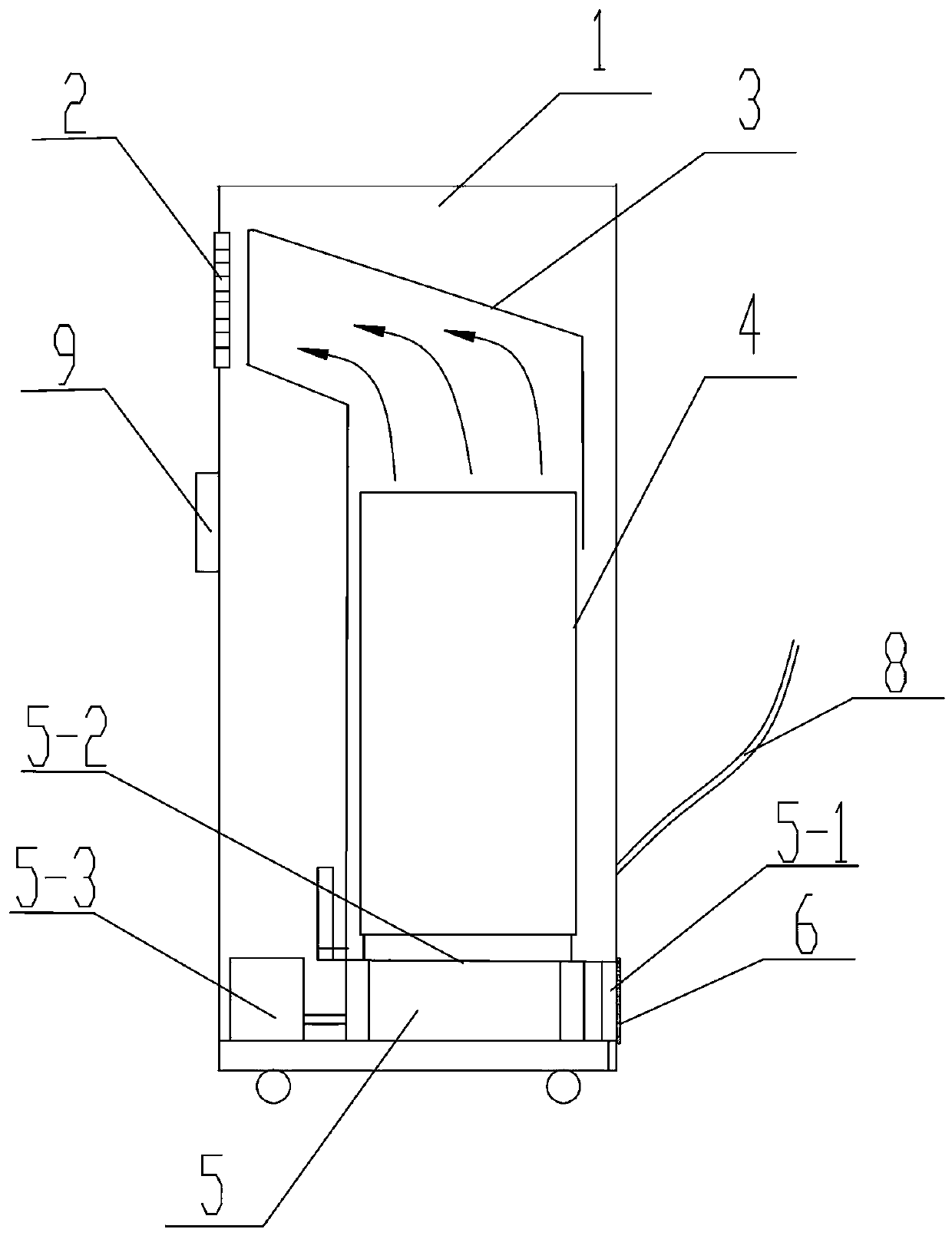

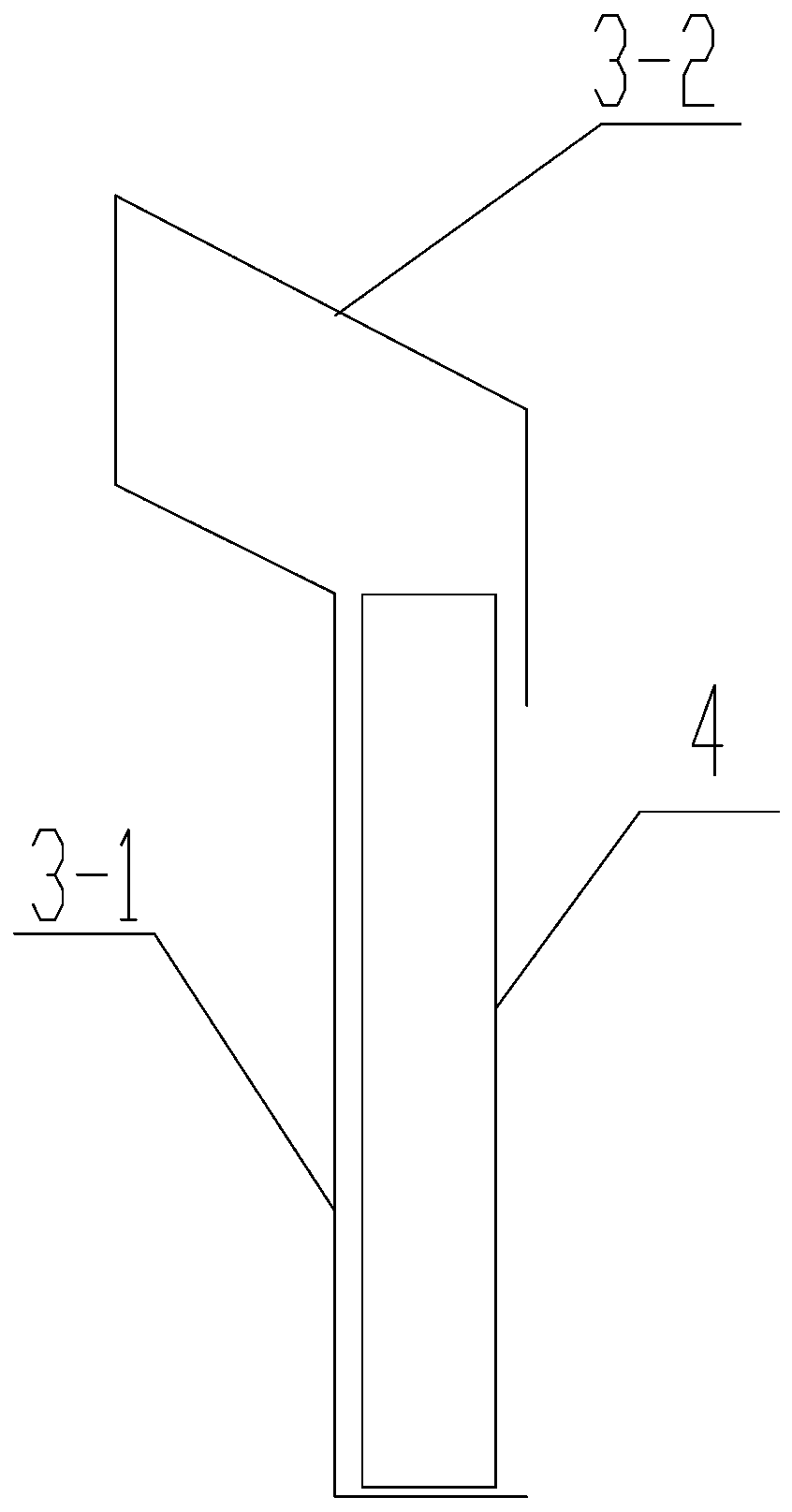

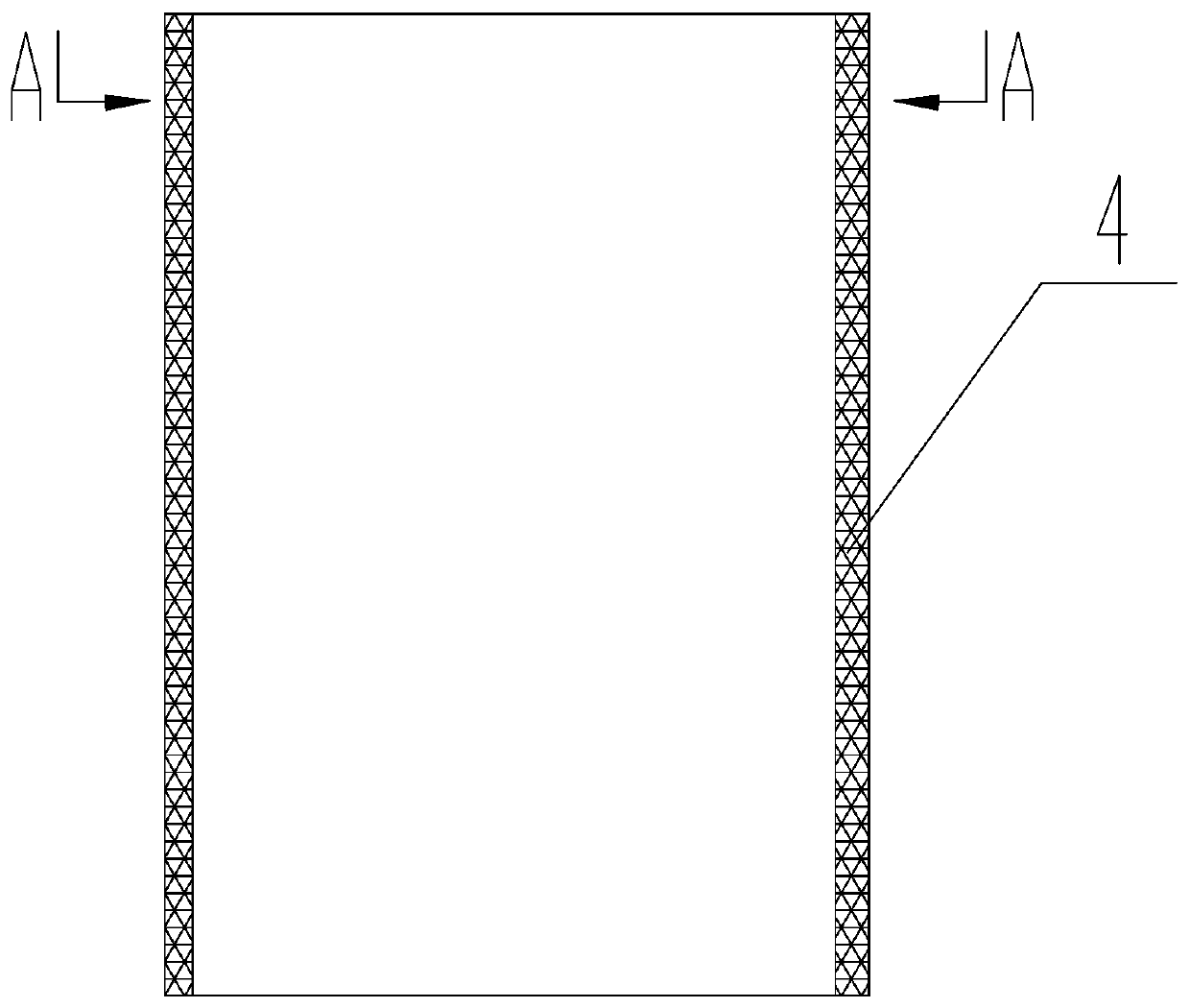

[0037] Such as Figure 1-4 As shown in the figure, a carbon fiber air filter sterilization and disinfection machine of the present invention includes an outer box body 1, an air inlet, a fresh air outlet 2, an induced draft fan and a filter sterilization device, a power connection line 8 arranged on the outer box body, and its power supply The connection line 8 is connected with the power supply, and it is characterized in that a first air inlet box 5, a second filter sterilization box 4 as a filter sterilization device and a third purified air exhaust box are arranged in the outer box body 1 from bottom to top 3. The fresh air outlet 2 is arranged on the upper part of the front panel of the outer box body 1, and a control panel 9 is also arranged on the front panel of the outer box body,

[0038] The first air inlet box 5 is arranged on the lower part of the outer box body 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap