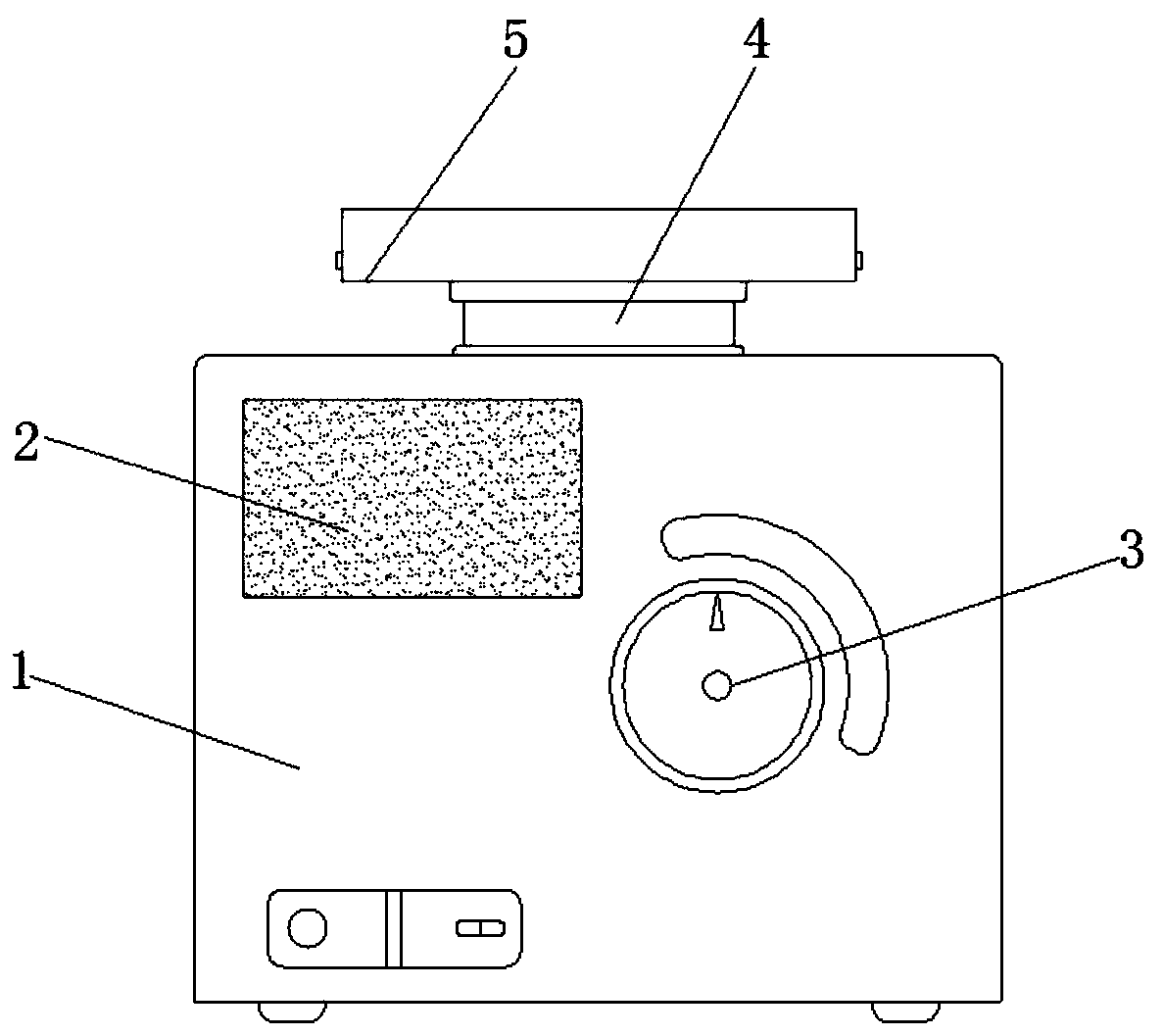

Reagent mixing device

A reagent and installation port technology, applied in the field of reagents, can solve problems such as inconvenient replacement, and achieve the effects of avoiding slippage and inconvenient disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

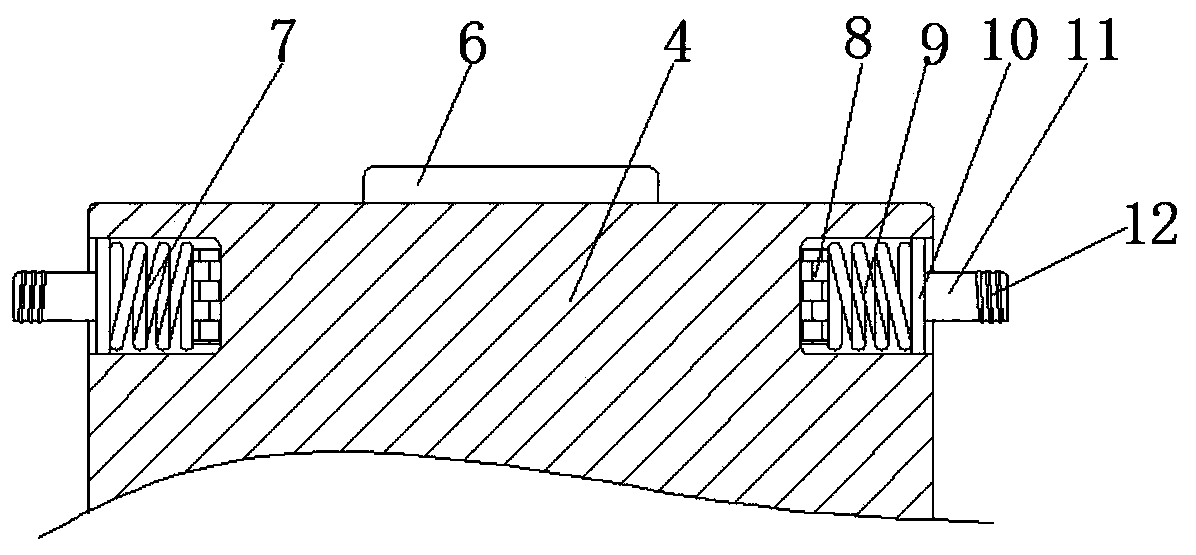

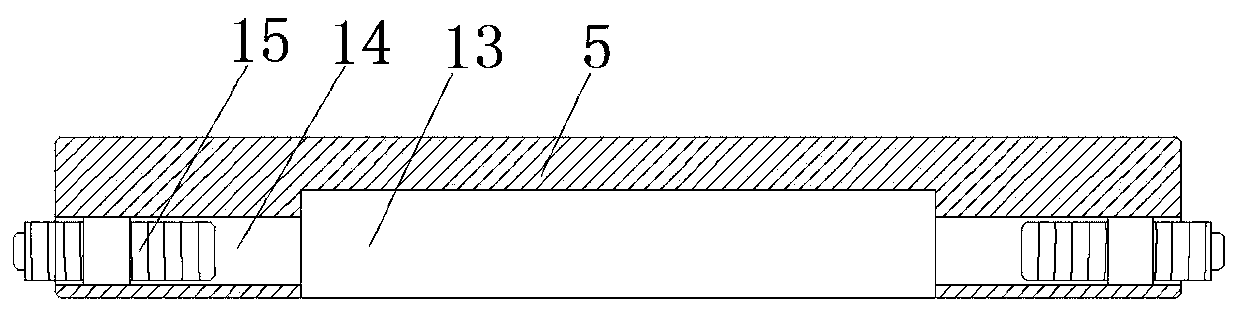

[0019] refer to Figure 1-4 , a mixing device for reagents, comprising a housing 1, the top outer wall of the housing 1 is provided with a rotating shaft 4, and the outer walls on both sides of the rotating shaft 4 are provided with limiting grooves, and the inner walls of the two limiting grooves are provided with limiting mechanisms 7. The top outer wall of the rotating shaft 4 is fixed with a push switch 6 by bolts, and the rotating shaft 4 is clamped with the same rotating head 5 through two limit mechanisms 7. The limit mechanism 7 includes an electromagnet 8, and the electromagnet 8 is fixed by bolts On the inner wall of one side of the limiting groove, the outer

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap